Table of Contents

What is ASTM A312? Everything You Need to Know

1.0 What is ASTM A312?

1.1 Overview of ASTM A312

- ASTM A312 is a standard specification for seamless, welded, and heavily cold-worked austenitic stainless steel pipes.

- It is widely used in industries requiring reliable performance in high-temperature and corrosive environments.

- Pipe sizes covered range from 1/8” to 30” diameters and thicknesses from SCH 10S to SCH 80S.

- Common material grades include TP304/304L and TP316/316L, known for their durability and corrosion resistance.

1.2 Key Features of ASTM A312 Pipes

- High resistance to corrosion and oxidation.

- Suitable for extreme temperatures and pressure applications.

- Versatile manufacturing types, including seamless, welded, and heavily cold-worked pipes.

2.0 Material Grades

2.1 TP304/304L:

- Excellent general corrosion resistance.

- Cost-effective and commonly used in food, beverage, and sanitary applications.

2.2 TP316/316L:

- Enhanced resistance to chloride-induced corrosion.

- Preferred for marine and chemical processing applications.

3.0 Types of Pipes

3.1 Seamless Pipes (SMLS):

Made without welding; high strength and pressure resistance.

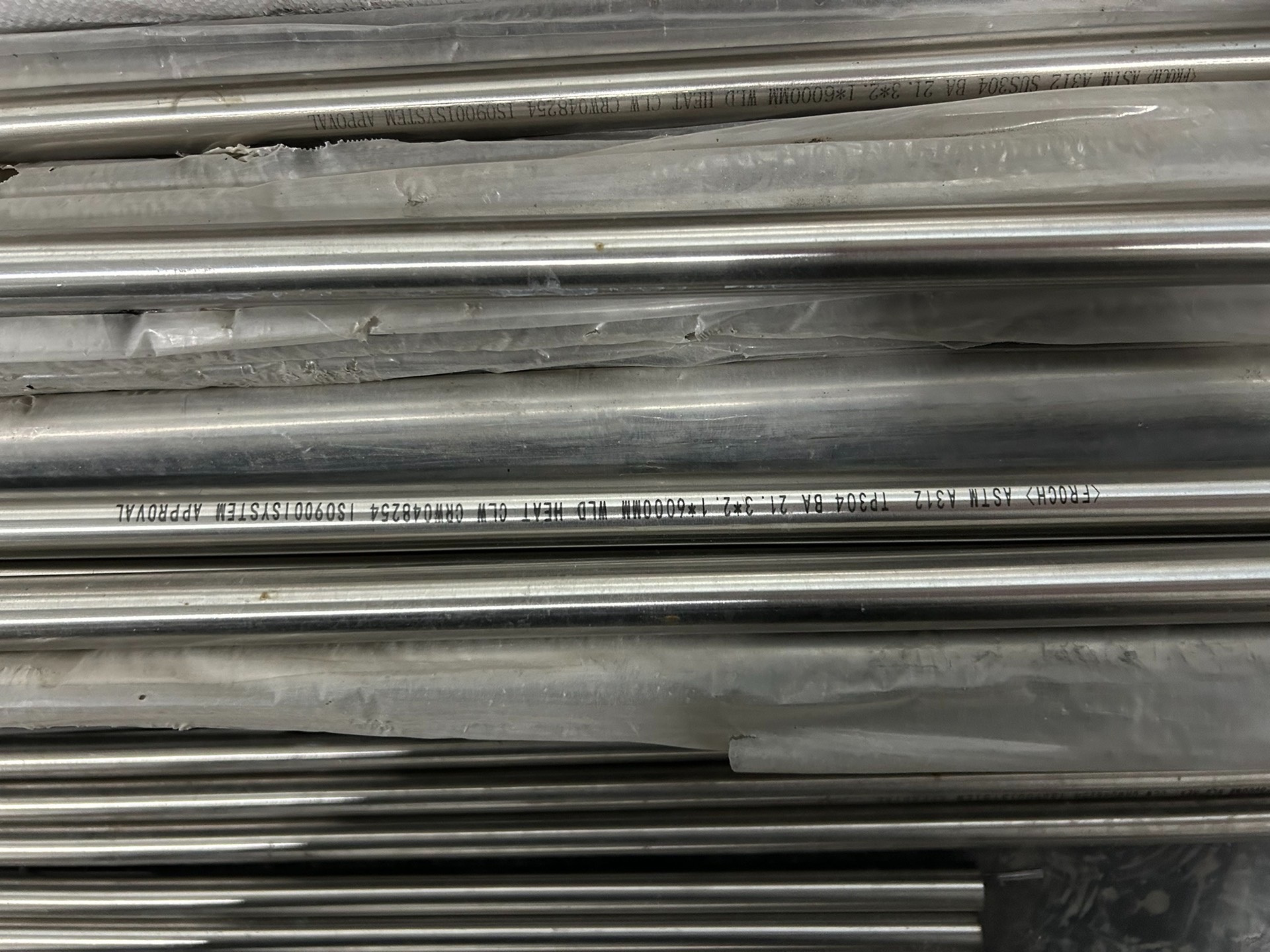

3.2 Welded Pipes (WLD):

Manufactured by automatic welding without filler metal.

3.3 Heavily Cold-Worked Pipes (HCW):

Produced by reducing thickness through cold working, providing enhanced mechanical properties.

4.0 Specifications

- Diameter Range: 1/8” to 30”.

- Wall Thickness: SCH 10S to SCH 80S.

- Heat Treatment: All pipes must undergo heat treatment for durability and corrosion resistance.

5.0 Applications

- Food and beverage industry.

- Chemical and petrochemical processing.

- Oil and gas transportation.

- Cryogenic systems and pressure containment.

6.0 Why Choose ASTM A312?

- Compliance with stringent international standards.

- Reliable performance in demanding environments.

- Long lifespan and cost-efficiency.

7.0 Conclusion

- ASTM A312 ensures consistent quality and reliability in stainless steel pipes for critical applications.

- Its versatile specifications make it a trusted choice across industries.

- For specific project needs, consult with industry experts to select the appropriate grade and type.

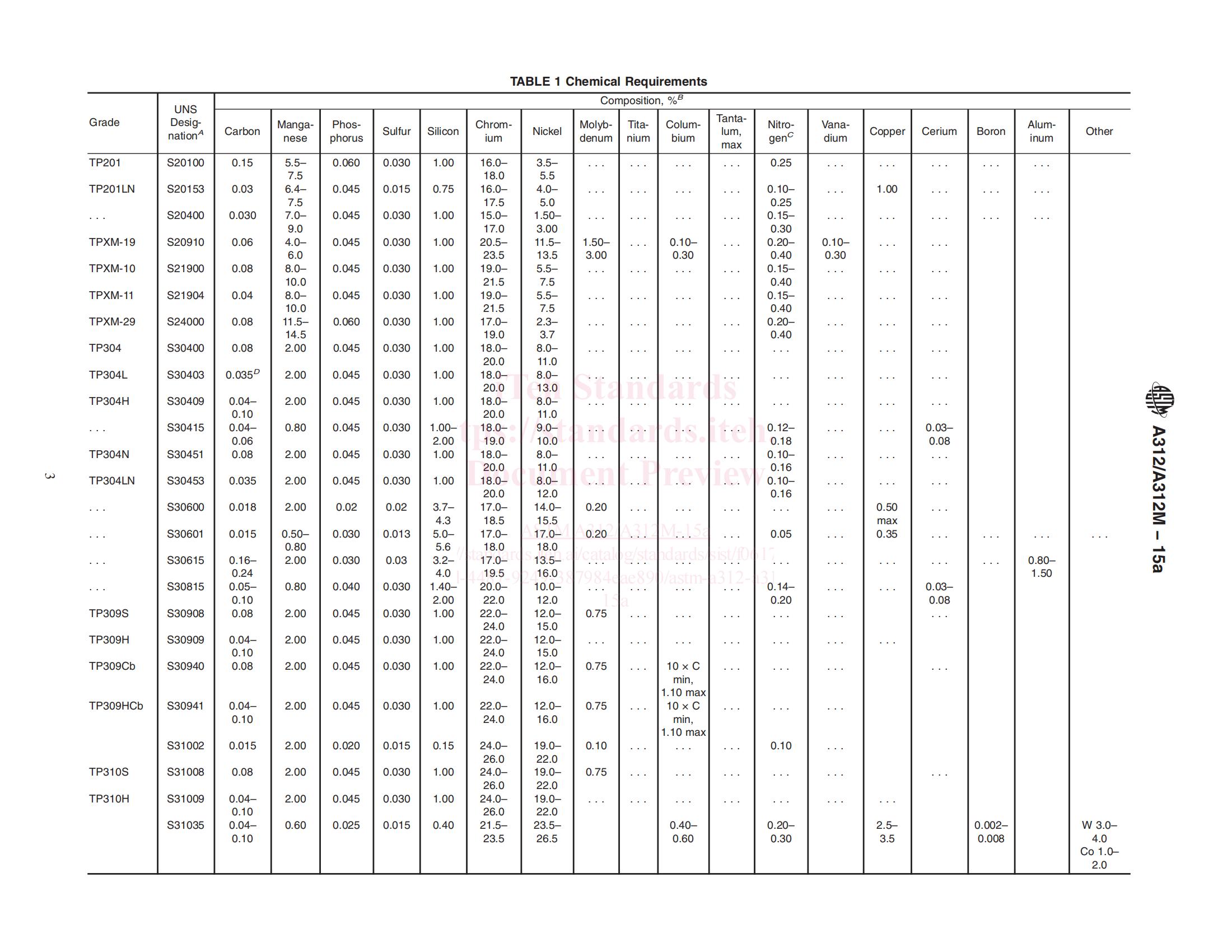

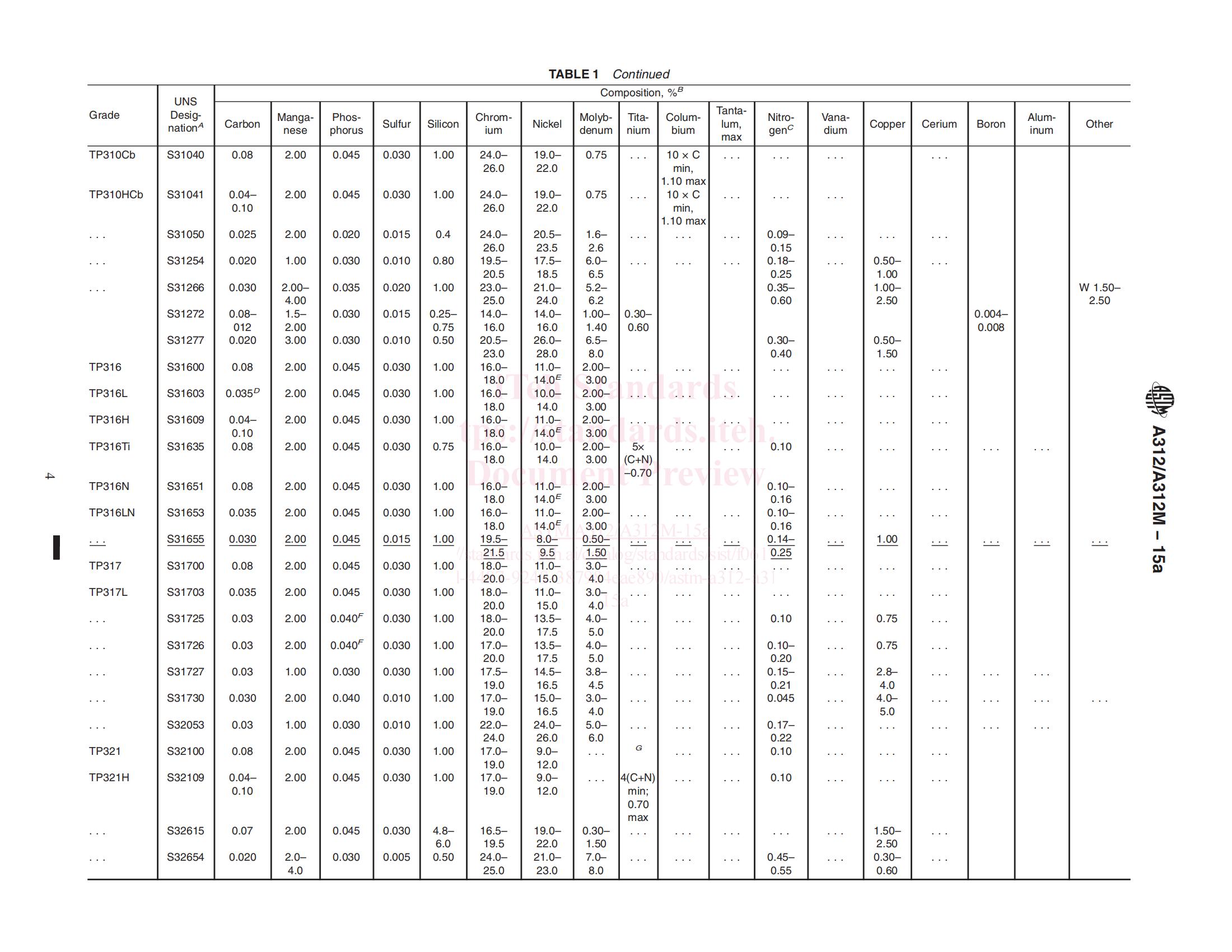

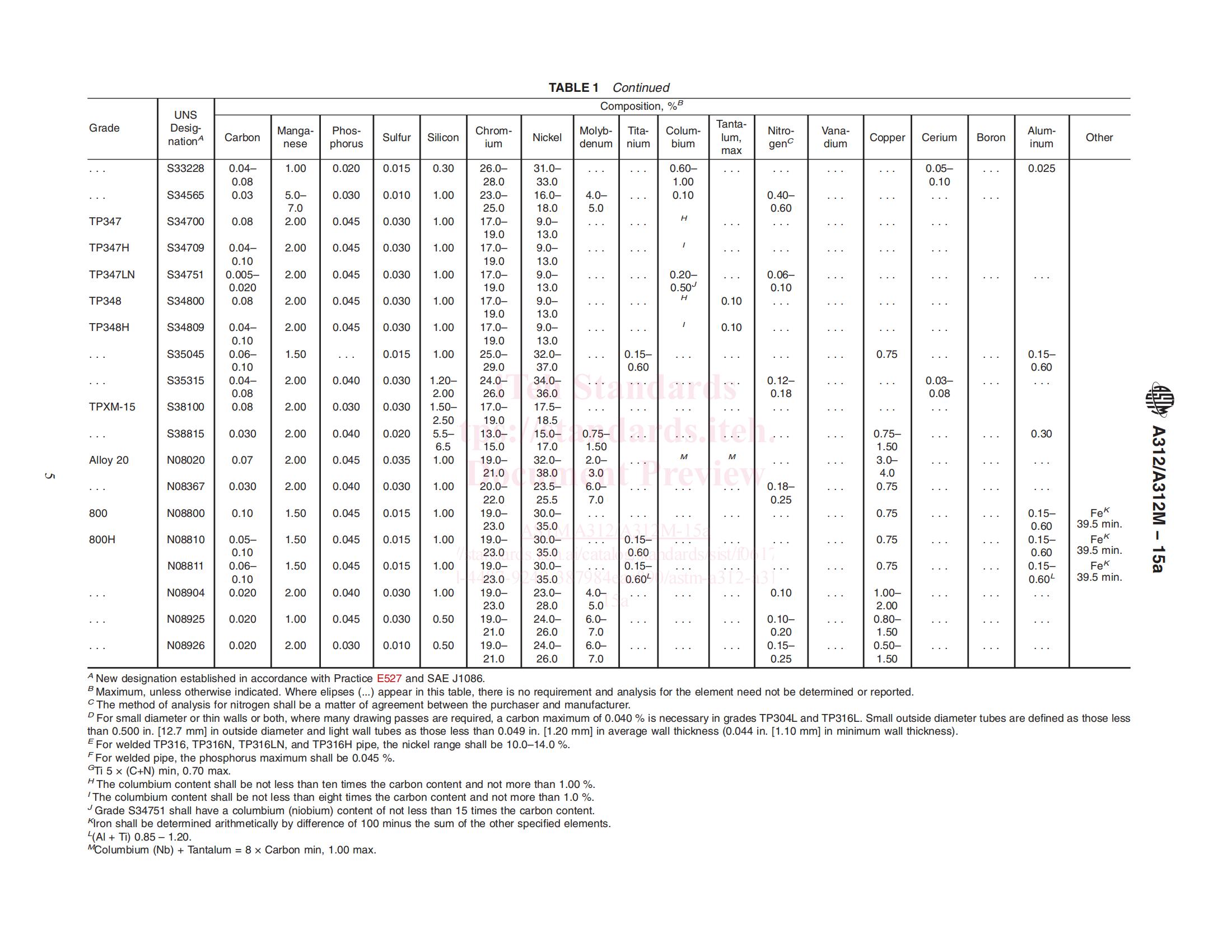

ASTM A312 Grades and Chemical Composition

| Grade | UNS Designation | Carbon (%) | Chromium (%) | Nickel (%) | Molybdenum (%) | Nitrogen (%) |

| TP304 | S30400 | 0.08 | 18.0-20.0 | 8.0-11.0 | – | – |

| TP304L | S30403 | 0.035 | 18.0-20.0 | 8.0-13.0 | – | – |

| TP316 | S31600 | 0.08 | 16.0-18.0 | 11.0-14.0 | 2.00-3.00 | – |

| TP316L | S31603 | 0.035 | 16.0-18.0 | 10.0-14.0 | 2.00-3.00 | – |

| TP321 | S32100 | 0.08 | 17.0-19.0 | 9.0-12.0 | – | 0.10 |

Mechanical Properties

| Grade | UNS Designation | Tensile Strength (min) [ksi/MPa] | Yield Strength (min) [ksi/MPa] |

| TP304 | S30400 | 75 [515] | 30 [205] |

| TP304L | S30403 | 70 [485] | 25 [170] |

| TP316 | S31600 | 75 [515] | 30 [205] |

| TP316L | S31603 | 70 [485] | 25 [170] |

| TP321 | S32100 | 75 [515] (Welded) | 30 [205] |

References:

https://www.astm.org/a0312_a0312m-24b.html