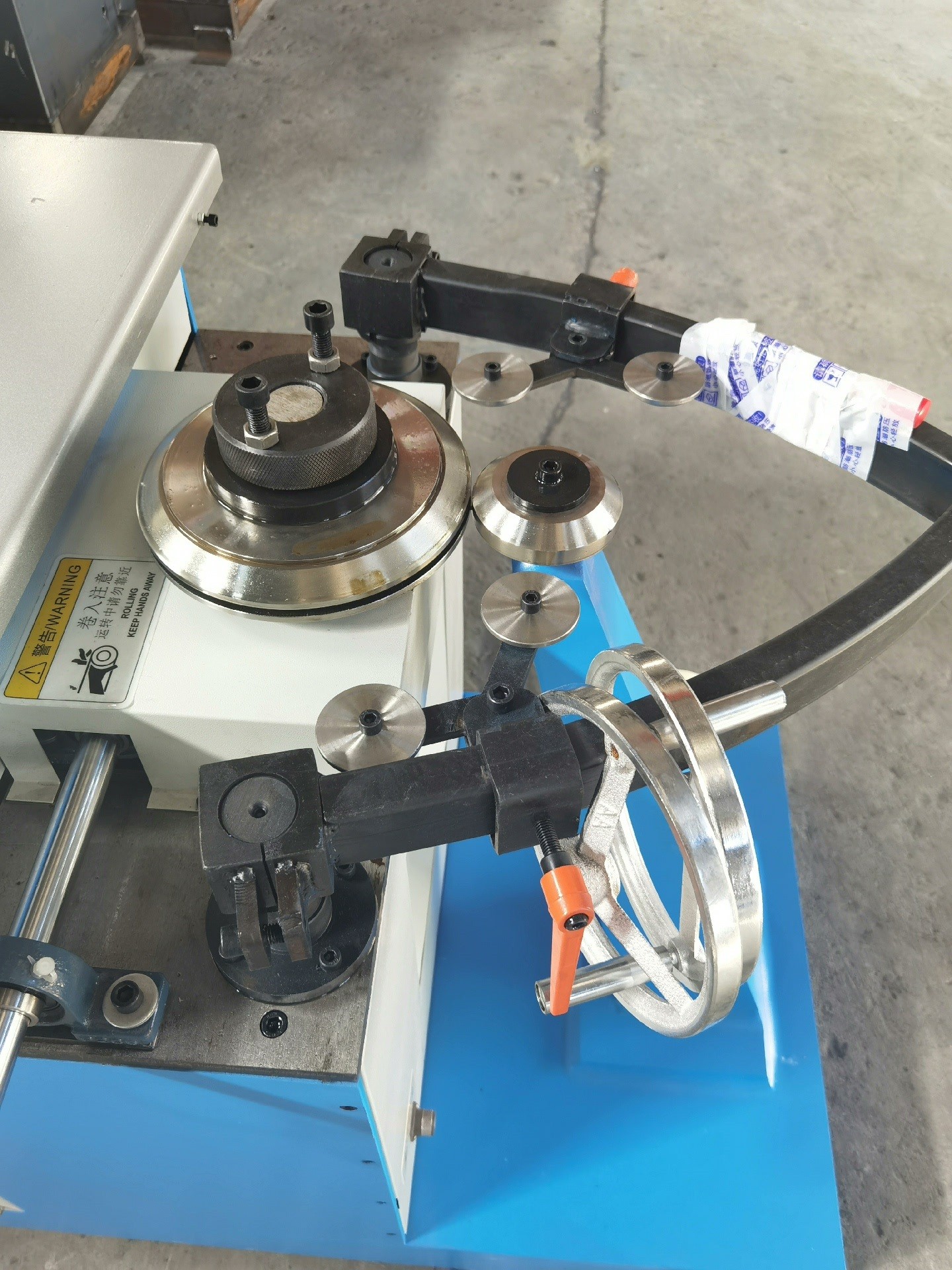

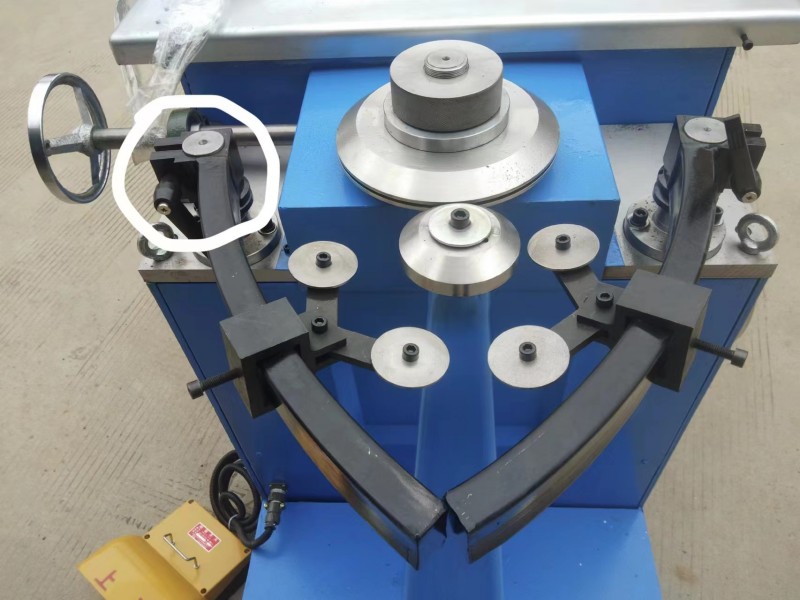

The machine features two separate workstations. On one side, the Flanger/Swager flanges one side of a cylindrical gore. By switching the mode, the upper table lowers, allowing the operator to swage the connecting side of the next gore.

On the opposite side, the Lockseamer completes the process by closing the seam into a standing rib, while another operator finalizes the operation.

Lockformer Dual Head Gore-Locker Key Features:

- High Flexibility: No need to replace equipment between different production tasks.

- High-Speed Production: Ensures consistent quality with fast production times.

- Large Capacity: Supports material thickness up to 1.5mm.

- Low Maintenance: Virtually maintenance-free, with no lubrication required.

- Precision Manufacturing: All rotating parts and tools are made from hardened steel for exceptional performance.

- Adjustable Speed: Equipped with two current inverters, allowing speed adjustment from 0-200% for greater flexibility in operation, particularly for varying elbow diameters.

Design and Durability:

- The frame is constructed with a full steel welding structure, ensuring high rigidity and strength.

- Heat-treated and vibrated steel plates enhance the overall durability.

- The machine utilizes a floor boring-milling process to ensure precision throughout the production.

- High-quality stainless steel is used for the operating table, making it resistant to wear and tear.

Elbow Gorelocker Forming Machine – Ideal for:

- Round Duct Elbow Production: Used for connecting circular ducts at corners or for turning connections.

- HVAC & Exhaust Systems: Essential for creating reliable, strong connections in ventilation and exhaust applications.

- High-Efficiency Manufacturing: Capable of producing hundreds of fittings per day with ease.

Vui lòng điền vào mẫu này để gửi yêu cầu báo giá. Một trong những thành viên trong nhóm của chúng tôi sẽ xem xét thông tin chi tiết và liên hệ trong vòng 12 giờ làm việc.