- 1.0Basic Requirements for Pipe Hole Punching Processing

- 2.0Application of ISO Standards in Pipe Hole Punching

- 2.1 ISO 286: Dimensional Tolerance Standards

- 2.2ISO 286 Dimensional Tolerance Table – Hole Diameter Tolerance

- 2.3ISO 286 Dimensional Tolerance Table – Shaft Diameter Tolerance

- 2.4ISO 286 IT Grade Tolerance Table

- 2.5ISO 286 Tolerance Band Calculation Table

- 2.6ISO 286 Diameter Tolerance Table (Hole and Shaft Diameters)

- 2.7ISO 286 Tolerance Band and Fit Table

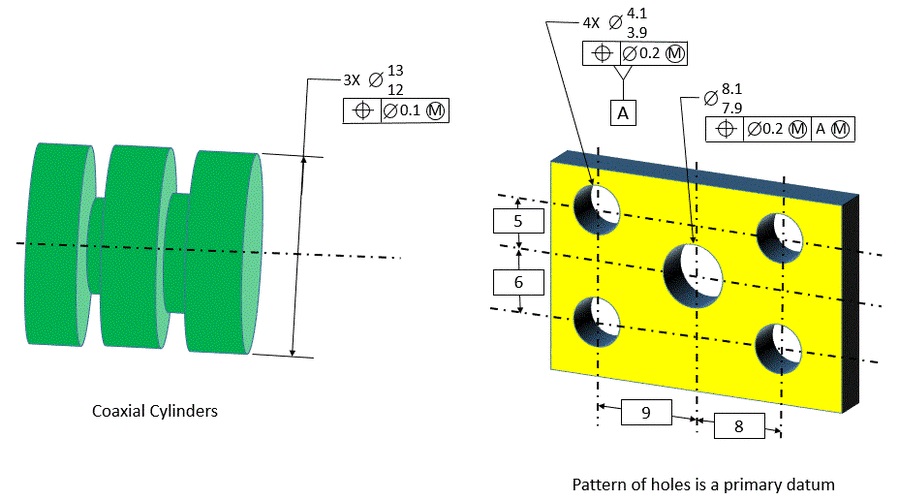

- 2.8 ISO 1101: Geometrical Tolerances

- 3.0Key Aspects of ISO 1101: Geometrical Tolerances

- 4.0ISO 2768: General Tolerances for Dimensions

- 5.0Hole Positioning and Other Special Considerations

- 6.0Clearance Guide for Punching Mild Steel

- 7.0Recommended Tonnage for Punching Mild Steel

Pipe hole punching is an important processing technology widely used in industries such as machinery, construction, and automotive. When performing pipe hole punching, ensuring the accuracy of hole diameter, hole position, and hole shape is crucial, especially when dealing with pipes of different materials and specifications.

ISO standards provide detailed specifications on tolerances, helping manufacturers achieve high-precision processing and ensure each hole meets design requirements, whether for square pipes or round pipes.

1.0Basic Requirements for Pipe Hole Punching Processing

Pipe hole punching is typically performed using a pipe-punching machine. The accuracy of the hole shape and position directly affects the adaptability and assembly effectiveness of the pipe in subsequent production stages. Therefore, controlling processing accuracy is key to improving product quality.

2.0Application of ISO Standards in Pipe Hole Punching

2.1 ISO 286: Dimensional Tolerance Standards

ISO 286 provides specifications for dimensional tolerances of pipe hole punching, covering hole diameter, pipe diameter, and other dimensional tolerances.

Adhering to the ISO 286 standard during pipe hole punching ensures that the punched pipe meets design requirements and minimizes rework or non-conforming products caused by tolerance issues.

| ISO Tolerances for Holes (ISO 286-2) | ||||||||||||||||||||

| Nominal hole sizes (mm) | ||||||||||||||||||||

| over | 3 | 6 | 10 | 18 | 30 | 40 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 225 | 250 | 280 | 315 | 355 |

| inc. | 6 | 10 | 18 | 30 | 40 | 50 | 65 | 80 | 100 | 120 | 140 | 160 | 180 | 200 | 225 | 250 | 280 | 315 | 355 | 400 |

| micrometres | ||||||||||||||||||||

| E6 | 28 | 34 | 43 | 53 | 66 | 79 | 94 | 110 | 129 | 142 | 161 | |||||||||

| 20 | 25 | 32 | 40 | 50 | 60 | 72 | 85 | 100 | 110 | 125 | ||||||||||

| E7 | 32 | 40 | 50 | 61 | 75 | 90 | 107 | 125 | 146 | 162 | 185 | |||||||||

| 20 | 25 | 32 | 40 | 50 | 60 | 72 | 85 | 100 | 110 | 125 | ||||||||||

| E11 | 95 | 115 | 142 | 170 | 210 | 250 | 292 | 335 | 390 | 430 | 485 | |||||||||

| 20 | 25 | 32 | 40 | 50 | 60 | 72 | 85 | 100 | 110 | 125 | ||||||||||

| E12 | 140 | 175 | 212 | 250 | 300 | 360 | 422 | 485 | 560 | 630 | 695 | |||||||||

| 20 | 25 | 32 | 40 | 50 | 60 | 72 | 85 | 100 | 110 | 125 | ||||||||||

| E13 | 200 | 245 | 302 | 370 | 440 | 520 | 612 | 715 | 820 | 920 | +1 015 | |||||||||

| 20 | 25 | 32 | 40 | 50 | 60 | 72 | 85 | 100 | 110 | 125 | ||||||||||

| F6 | 18 | 22 | 27 | 33 | 41 | 49 | 58 | 68 | 79 | 88 | 98 | |||||||||

| 10 | 13 | 16 | 20 | 2 | 30 | 36 | 43 | 50 | 56 | 62 | ||||||||||

| F7 | 22 | 28 | 34 | 41 | 50 | 60 | 71 | 83 | 96 | 108 | 119 | |||||||||

| 10 | 13 | 16 | 20 | 25 | 30 | 36 | 43 | 50 | 56 | 62 | ||||||||||

| F8 | 28 | 35 | 43 | 53 | 64 | 76 | 90 | 106 | 122 | 137 | 151 | |||||||||

| 10 | 13 | 16 | 20 | 25 | 30 | 36 | 43 | 50 | 56 | 62 | ||||||||||

| G6 | 12 | 14 | 17 | 20 | 25 | 29 | 34 | 39 | 44 | 49 | 54 | |||||||||

| 4 | 5 | 6 | 7 | 9 | 10 | 12 | 14 | 15 | 17 | 18 | ||||||||||

| G7 | 16 | 20 | 24 | 28 | 34 | 40 | 47 | 54 | 61 | 69 | 75 | |||||||||

| 4 | 5 | 6 | 7 | 9 | 10 | 12 | 14 | 15 | 17 | 18 | ||||||||||

| G8 | 22 | 27 | 33 | 40 | 48 | 56 | 66 | 77 | 87 | 98 | 107 | |||||||||

| 4 | 5 | 6 | 7 | 9 | 10 | 12 | 14 | 15 | 17 | 18 | ||||||||||

| H6 | 8 | 9 | 11 | 13 | 16 | 19 | 22 | 25 | 29 | 32 | 36 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| H7 | 12 | 15 | 18 | 21 | 25 | 30 | 35 | 40 | 46 | 52 | 57 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| H8 | 18 | 22 | 27 | 33 | 39 | 46 | 54 | 63 | 72 | 81 | 89 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| H9 | 30 | 36 | 43 | 52 | 62 | 74 | 87 | 100 | 115 | 130 | 140 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| H10 | 48 | 58 | 70 | 84 | 100 | 120 | 140 | 160 | 185 | 210 | 230 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| H11 | 75 | 90 | 110 | 130 | 160 | 190 | 220 | 250 | 290 | 320 | 360 | |||||||||

| 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | ||||||||||

| J6 | 5 | 5 | 6 | 8 | 10 | 13 | 16 | 18 | 22 | 25 | 29 | |||||||||

| -3 | -4 | -5 | -5 | -6 | -6 | -6 | -7 | -7 | -7 | -7 | ||||||||||

| J7 | 6 | 8 | 10 | 12 | 14 | 18 | 22 | 26 | 30 | 36 | 39 | |||||||||

| -6 | -7 | -8 | -9 | -11 | -12 | -13 | -14 | -16 | -16 | -18 | ||||||||||

| J8 | 10 | 12 | 15 | 20 | 24 | 28 | 34 | 41 | 47 | 55 | 60 | |||||||||

| -8 | -10 | -12 | -13 | -15 | -18 | -20 | -22 | -25 | -26 | -29 | ||||||||||

| JS6 | 4 | 4.5 | 5.5 | 6.5 | 8 | 9.5 | 11 | 12.5 | 14.5 | 16 | 18 | |||||||||

| -4 | -4.5 | -5.5 | -6.5 | -8 | -9.5 | -11 | -12.5 | -14.5 | -16 | -18 | ||||||||||

| JS7 | 6 | 7.5 | 9 | 10.5 | 12.5 | 15 | 17.5 | 20 | 23 | 26 | 28.5 | |||||||||

| -6 | -7.5 | -9 | -10.5 | -12.5 | -15 | -17.5 | -20 | -23 | -26 | -28.5 | ||||||||||

| JS8 | 9 | 11 | 13.5 | 16.5 | 19.5 | 23 | 27 | 31.5 | 36 | 40.5 | 44.5 | |||||||||

| -9 | -11 | -13.5 | -16.5 | -19.5 | -23 | -27 | -31.5 | -36 | -40.5 | -44.5 | ||||||||||

| K6 | 2 | 2 | 2 | 2 | 3 | 4 | 4 | 4 | 5 | 5 | 7 | |||||||||

| -6 | -7 | -9 | -11 | -13 | -15 | -18 | -21 | -24 | -27 | -29 | ||||||||||

| K7 | 3 | 5 | 6 | 6 | 7 | 9 | 10 | 12 | 13 | 16 | 17 | |||||||||

| -9 | -10 | -12 | -15 | -18 | -21 | -25 | -28 | -33 | -36 | -40 | ||||||||||

| K8 | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | 22 | 25 | 28 | |||||||||

| -13 | -16 | -19 | -23 | -27 | -32 | -38 | -43 | -50 | -56 | -61 | ||||||||||

| M6 | -1 | -3 | -4 | -4 | -4 | -5 | -6 | -8 | -8 | -9 | -10 | |||||||||

| -9 | -12 | -15 | -17 | -20 | -24 | -28 | -33 | -37 | -41 | -46 | ||||||||||

| M7 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | |||||||||

| -12 | -15 | -18 | -21 | -25 | -30 | -35 | -40 | -46 | -52 | -57 | ||||||||||

| M8 | 2 | 1 | 2 | 4 | 5 | 5 | 6 | 8 | 9 | 9 | 11 | |||||||||

| -16 | -21 | -25 | -29 | -34 | -41 | -48 | -55 | -63 | -72 | -78 | ||||||||||

| N6 | -5 | -7 | -9 | -11 | -12 | -14 | -16 | -20 | -22 | -25 | -26 | |||||||||

| -13 | -16 | -20 | -24 | -28 | -33 | -38 | -45 | -51 | -57 | -62 | ||||||||||

| N7 | -4 | -4 | -5 | -7 | -8 | -9 | -10 | -12 | -14 | -14 | -16 | |||||||||

| -16 | -19 | -23 | -28 | -33 | -39 | -45 | -52 | -60 | -66 | -73 | ||||||||||

| N8 | -2 | -3 | -3 | -3 | -3 | -4 | -4 | -4 | -5 | -5 | -5 | |||||||||

| -20 | -25 | -30 | -36 | -42 | -50 | -58 | -67 | -77 | -86 | -94 | ||||||||||

| P6 | -9 | -12 | -15 | -18 | -21 | -26 | -30 | -36 | -41 | -47 | -51 | |||||||||

| -17 | -21 | -26 | -31 | -37 | -45 | -52 | -61 | -70 | -79 | -87 | ||||||||||

| P7 | -8 | -9 | -11 | -14 | -17 | -21 | -24 | -28 | -33 | -36 | -41 | |||||||||

| -20 | -24 | -29 | -35 | -42 | -51 | -59 | -68 | -79 | -88 | -98 | ||||||||||

| P8 | -12 | -15 | -18 | -22 | -26 | -32 | -37 | -43 | -50 | -56 | -62 | |||||||||

| -30 | -37 | -45 | -55 | -65 | -78 | -91 | -106 | -122 | -137 | -151 | ||||||||||

| R6 | -12 | -16 | -20 | -24 | -29 | -35 | -37 | -44 | -47 | -56 | -58 | -61 | -68 | -71 | -75 | -85 | -89 | -97 | -103 | |

| -20 | -25 | -31 | -37 | -45 | -54 | -56 | -66 | -69 | -81 | -83 | -86 | -97 | -100 | -104 | -117 | -121 | -133 | -139 | ||

| R7 | -11 | -13 | -16 | -20 | -25 | -30 | -32 | -38 | -41 | -48 | -50 | -53 | -60 | -63 | -67 | -74 | -78 | -87 | -93 | |

| -23 | -28 | -34 | -41 | -50 | -60 | -62 | -73 | -76 | -88 | -90 | -93 | -106 | -109 | -113 | -126 | -130 | -144 | -150 | ||

2.2ISO 286 Dimensional Tolerance Table – Hole Diameter Tolerance

This table describes the hole diameter tolerance based on different IT grades (tolerance grades) for various hole diameter ranges.

| Size Range (mm) | IT7 Tolerance (mm) | IT8 Tolerance (mm) | IT9 Tolerance (mm) |

| 1 – 3 | ±0.020 | ±0.025 | ±0.030 |

| 3 – 6 | ±0.025 | ±0.030 | ±0.035 |

| 6 – 10 | ±0.030 | ±0.035 | ±0.040 |

| 10 – 18 | ±0.035 | ±0.040 | ±0.045 |

| 18 – 30 | ±0.040 | ±0.045 | ±0.050 |

| 30 – 50 | ±0.050 | ±0.060 | ±0.070 |

2.3ISO 286 Dimensional Tolerance Table – Shaft Diameter Tolerance

This table shows the tolerance for shaft diameter based on different IT grades.

| Size Range (mm) | IT7 Tolerance (mm) | IT8 Tolerance (mm) | IT9 Tolerance (mm) |

| 1 – 3 | ±0.020 | ±0.025 | ±0.030 |

| 3 – 6 | ±0.025 | ±0.030 | ±0.035 |

| 6 – 10 | ±0.030 | ±0.035 | ±0.040 |

| 10 – 18 | ±0.035 | ±0.040 | ±0.045 |

| 18 – 30 | ±0.045 | ±0.050 | ±0.060 |

| 30 – 50 | ±0.060 | ±0.070 | ±0.080 |

2.4ISO 286 IT Grade Tolerance Table

This table shows the tolerance range for different IT grades, helping to choose the appropriate tolerance precision.

| IT Grade | Tolerance Range (mm) |

| IT01 | ±0.0025 |

| IT2 | ±0.005 |

| IT3 | ±0.010 |

| IT4 | ±0.015 |

| IT5 | ±0.025 |

| IT6 | ±0.050 |

| IT7 | ±0.080 |

| IT8 | ±0.120 |

| IT9 | ±0.180 |

2.5ISO 286 Tolerance Band Calculation Table

This table shows the allowable deviation between holes and shafts for different tolerance bands (such as H7 and H7).

| Fit Type | Hole Tolerance (mm) | Shaft Tolerance (mm) |

| H7 | ±0.025 | 0.000 |

| H8 | ±0.030 | 0.000 |

| h7 | ±0.025 | ±0.000 |

| h8 | ±0.030 | ±0.000 |

2.6ISO 286 Diameter Tolerance Table (Hole and Shaft Diameters)

This table shows the tolerances for hole and shaft diameters within different size ranges, applicable to fit precision control in mechanical processing.

| Size Range (mm) | Hole Tolerance (mm) | Shaft Tolerance (mm) |

| 3 – 6 | ±0.025 | ±0.020 |

| 6 – 10 | ±0.035 | ±0.030 |

| 10 – 18 | ±0.045 | ±0.035 |

| 18 – 30 | ±0.060 | ±0.045 |

| 30 – 50 | ±0.080 | ±0.060 |

2.7ISO 286 Tolerance Band and Fit Table

This table lists the different tolerance bands (such as H7, h7, and P7) for hole and shaft fits, helping to ensure fit accuracy.

| Fit Type | Hole Tolerance (mm) | Shaft Tolerance (mm) |

| H7 | ±0.025 | 0.000 |

| H8 | ±0.030 | 0.000 |

| h7 | ±0.025 | ±0.000 |

| h8 | ±0.030 | ±0.000 |

| P7 | ±0.030 | 0.000 |

2.8 ISO 1101: Geometrical Tolerances

The ISO 1101 standard ensures that the hole position and shape after punching meet design requirements, particularly for precision machining, where hole position accuracy is crucial. By appropriately setting geometrical tolerances, manufacturers can guarantee the accurate position and shape of each hole, avoiding errors during assembly and welding.

ISO 1101 is an international standard that defines geometrical tolerances for mechanical parts, such as their shape, dimensional accuracy, and assembly requirements. It provides symbols and methods for indicating allowable geometrical deviations in manufacturing and assembly processes. Geometrical tolerances are typically applied to parts that require high precision, such as bearings, gears, and racks.

3.0Key Aspects of ISO 1101: Geometrical Tolerances

Geometrical Tolerance Symbols

ISO 1101 defines various symbols to represent different geometrical requirements. Common geometrical tolerance symbols include:

- Straightness (⎯): Ensures a surface or contour remains straight within a specified range.

- Flatness (▭): Ensures a surface remains within a specified flat plane.

- Roundness (O): Ensures the roundness of a circular contour is within an acceptable range.

- Cylindricity (◯): Ensures a cylindrical shape remains within a specified tolerance range for both axis and diameter.

- Perpendicularity (⊥): Ensures the relationship between two surfaces or axes is perpendicular.

- Parallelism (∥): Ensures two surfaces or lines remain parallel.

- Concentricity (⌀): Ensures the axes of two circular features overlap.

- Position Tolerance (⊙): Defines the location tolerance for holes, shafts, or other features in space.

3.1Geometrical Tolerances with Dimensioning

Geometrical tolerances are usually combined with dimensioning to specify the precise shape and assembly requirements of a workpiece. For example:

- Hole geometrical tolerances: Often used to specify the position and deviation of holes in a plane.

- Shaft geometrical tolerances: Can include straightness, roundness, or concentricity.

3.2Applications of Geometrical Tolerances

In practice, geometrical tolerances are used alongside other dimensional tolerances to ensure the product can function correctly during assembly and use. ISO 1101 provides detailed rules for interpreting and applying these tolerance symbols to ensure manufacturing processes meet design specifications.

3.3Common Geometrical Tolerance Tables

| Tolerance Type | Symbol | Meaning | Application Range |

| Straightness | ⎯ | Ensures a surface or line is within a specified straightness range | Used for all linear contours and surfaces |

| Flatness | ▭ | Ensures a surface is flat, with all points within a specified plane | Used for flat machined parts |

| Roundness | O | Ensures a contour is within a specified roundness range | Used for circular features such as shafts and holes |

| Cylindricity | ◯ | Ensures a cylindrical surface is within a specified cylindricity range | Used for all cylindrical parts |

| Perpendicularity | ⊥ | Ensures a perpendicular relationship between two surfaces or axes | Used for parts requiring precise assembly |

| Parallelism | ∥ | Ensures two surfaces or lines are parallel | Used for components requiring precise assembly |

4.0ISO 2768: General Tolerances for Dimensions

ISO 2768 provides general tolerance guidelines for dimensions in mechanical design, which include dimensional tolerances for both linear and angular dimensions. It is often used for non-critical dimensions that don’t require precise tolerance control. For pipe hole punching, this standard helps maintain an overall dimensional accuracy for parts that aren’t directly involved in key functional connections but still need to meet quality standards.

4.1ISO 2768 Tolerance Table – General Tolerances for Linear Dimensions

| Dimension (mm) | Tolerance (mm) |

| 0.5 – 3 | ±0.05 |

| 3 – 6 | ±0.10 |

| 6 – 30 | ±0.15 |

| 30 – 120 | ±0.20 |

| 120 – 400 | ±0.30 |

| 400 – 1000 | ±0.50 |

4.2ISO 2768 Tolerance Table – General Tolerances for Angular Dimensions

| Angle (°) | Tolerance (°) |

| 0 – 10 | ±1.0 |

| 10 – 30 | ±1.5 |

| 30 – 90 | ±2.0 |

| 90 – 180 | ±2.5 |

These tolerances are applied to ensure that the parts can be assembled correctly, even if they are not as critical in terms of dimensional precision.

5.0Hole Positioning and Other Special Considerations

In addition to dimensional and geometrical tolerances, hole position control is another critical factor in pipe hole punching. The position of holes, relative to the pipe’s overall structure, must meet the design’s specified positional tolerances. ISO 1101 specifies how to define position tolerances for holes, ensuring the holes are punched in the right locations relative to the pipe.

Position Tolerance (ISO 1101): The position tolerance defines the acceptable deviation for a hole’s location. It is usually defined by a reference point or datum and is critical for ensuring that holes line up correctly with other parts, such as when the pipes are welded or fitted with other components.

6.0Clearance Guide for Punching Mild Steel

| Clearance Guide for Punching Mild Steel | |||||||||||||||||||

| Thickness of Mild Steel | |||||||||||||||||||

| Punch Size |

1/8 | 1/4 | 3/8 | 1/2 | 5/8 | 3/4 | 7/8 | 1″ | |||||||||||

| 3/16 | 13/64 | ||||||||||||||||||

| 1/4 | 17/64 | ||||||||||||||||||

| 5/16 | 21/64 | 11/32 | |||||||||||||||||

| 3/8 | 25/64 | 13/32 | 13/32 | ||||||||||||||||

| 7/16 | 29/64 | 15/32 | 15/32 | ||||||||||||||||

| 1/2 | 33/64 | 17/32 | 17/32 | 9/16 | |||||||||||||||

| 9/16 | 37/64 | 19/32 | 19/32 | 5/8 | |||||||||||||||

| 5/8 | 41/64 | 21/32 | 21/32 | 11/16 | 11/16 | ||||||||||||||

| 11/16 | 45/64 | 23/32 | 23/32 | 3/4 | 3/4 | ||||||||||||||

| 3/4 | 49/64 | 25/32 | 25/32 | 13/16 | 13/16 | 27/32 | |||||||||||||

| 13/16 | 53/64 | 27/32 | 27/32 | 7/8 | 7/8 | 29/32 | |||||||||||||

| 7/8 | 57/64 | 29/32 | 29/32 | 15/16 | 15/16 | 31/32 | 31/32 | ||||||||||||

| 15/16 | 61/64 | 31/32 | 31/32 | 1 | 1 | 1-1/32 | 1-1/32 | ||||||||||||

| 1 | 1-1/64 | 1-1/32 | 1-1/32 | 1-1/16 | 1-1/16 | 1-3/32 | 1-3/32 | 1-1/8 | |||||||||||

| 1-1/16 | 1-5/64 | 1-3/32 | 1-3/32 | 1-1/8 | 1-1/8 | 1-5/32 | 1-5/32 | 1-3/16 | |||||||||||

| 1-1/8 | 1-9/64 | 1-5/32 | 1-5/32 | 1-3/16 | 1-3/16 | 1-7/32 | 1-7/32 | 1-1/4 | |||||||||||

| 1-3/16 | 1-13/64 | 1-7/32 | 1-7/32 | 1-1/4 | 1-1/4 | 1-9/32 | 1-9/32 | 1-5/16 | |||||||||||

| 1-1/4 | 1-17/64 | 1-9/32 | 1-9/32 | 1-5/16 | 1-5/16 | 1-11/32 | 1-11/32 | 1-3/8 | |||||||||||

| 1-5/16 | 1-21/64 | 1-11/32 | 1-11/32 | 1-3/8 | 1-3/8 | 1-13/32 | 1-13/32 | 1-7/16 | |||||||||||

| 1-3/8 | 1-25/64 | 1-13/32 | 1-13/32 | 1-7/16 | 1-7/16 | 1-15/32 | 1-15/32 | 1-1/2 | |||||||||||

| 1-7/16 | 1-29/64 | 1-15/32 | 1-15/32 | 1-1/2 | 1-1/2 | 1-17/32 | 1-17/32 | 1-9/16 | |||||||||||

| 1-1/2 | 1-33/64 | 1-17/32 | 1-17/32 | 1-9/16 | 1-9/16 | 1-19/32 | 1-19/32 | 1-5/8 | |||||||||||

7.0Recommended Tonnage for Punching Mild Steel

| Recommended Tonnage for Punching Mild Steel | |||||||||||||||||||||

| Thickness of Mild Steel |

Punch Size | ||||||||||||||||||||

| 3/16 | 1/4 | 5/16 | 3/8 | 7/16 | 1/2 | 9/16 | 5/8 | 11/16 | 3/4 | 13/16 | 7/8 | 15/16 | 1″ | 1-1/8 | 1-1/4 | ||||||

| 3/16 1/4 |

.187 | 3 | 4 | 5 | 6 | 7 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 17 | 19 | ||||

| .250 | 5 | 6 | 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 25 | ||||||

| 3/8 | .375 | 11 | 13 | 15 | 17 | 19 | 21 | 22 | 24 | 26 | 28 | 30 | 34 | 38 | |||||||

| 1/2 | .500 | 20 | 22 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 45 | 50 | |||||||||

| 5/8 | .625 | 31 | 34 | 38 | 41 | 44 | 47 | 50 | 56 | 62 | |||||||||||

| 3/4 | .750 | 45 | 49 | 52 | 56 | 60 | 68 | 75 | |||||||||||||

| 7/8 | .875 | 61 | 66 | 70 | 79 | 88 | |||||||||||||||

| 1 | |||||||||||||||||||||

| 1.000 | 80 | 90 | |||||||||||||||||||

7.1Conclusion

ISO tolerance standards play a crucial role in ensuring that pipe hole punching and other machining operations are performed accurately. By following these internationally recognized standards, manufacturers can ensure that the punched holes meet both dimensional and geometrical requirements, resulting in high-quality, reliable products.

7.2Appendix: Commonly Used Tolerances in Pipe Hole Punching

| Type | Tolerance (mm) | Notes |

| Hole Diameter | ±0.10 – ±0.20 | Dependent on pipe size and material |

| Hole Position | ±0.10 – ±0.20 | Based on the reference point or datum |

| Perpendicularity | ±0.05 – ±0.10 | Ensures holes are perpendicular to the pipe |

| Roundness of Holes | ±0.05 – ±0.10 | Ensures holes remain circular |

| Flatness of Hole | ±0.05 – ±0.10 | Ensures the punched hole surface remains flat |

By referencing these tables and following the appropriate standards, manufacturers can ensure that the hole-punching process maintains precision and that the pipes fit together correctly in the final product.

https://www.dimensionalconsulting.com/tolerance-of-position.html

https://slideplayer.com/slide/15857807/

https://www.clevelandsteeltool.com/