- 1.0What is a Standing Seam Metal Roof?

- 2.0Types of Standing Seam Panel Profiles

- 3.0Advantages of Standing Seam Metal Roofs

- 4.0Steel, Aluminum, or Galvanized Steel: Which Material is Best for Your Roof?

- 5.0Key Factors Influencing the Cost of a Standing Seam Metal Roof

- 6.0Standing Seam Metal Roof Colors and Styles

- 7.0Standing Seam vs. Corrugated Metal Roofs: Which is Better?

- 8.0Standing Seam Metal Roof Cost FAQs

1.0What is a Standing Seam Metal Roof?

Among all metal roof types, standing seam roofs are the most popular because homeowners increasingly seek durable, modern-looking products that protect roof structures.

1.1Structure and Composition

standing seam metal roof is typically composed of metal panels (usually made from materials such as aluminum, galvanized steel, stainless steel, copper, etc.) that are directly connected together through vertical seams, forming an integrated roof panel system. The primary feature of this system is that the fasteners, such as clamps or flanges, are hidden beneath the metal decking.

The most distinctive characteristic of this roofing type is that the seams (also known as “standing seams”) are raised above the surface of the metal panels, creating visible vertical lines. The spacing between these seams typically ranges from 12 to 24 inches.

1.2Seam Design

The standing seam is key to this integrated roofing system:

- Waterproofing:The raised seam elevates the panel joints above the panel surface, preventing rain and snow from directly entering the seams between metal panels.

- Hidden Fasteners:The panels are secured to the building’s roofing structure using hidden fasteners or clips, reducing the risk of aging, cracking, and leaks that exposed screws might cause.

1.3Thermal Expansion and Contraction:

Metal materials tend to expand and contract with temperature changes. The seam design allows the panels to expand or contract freely, preventing deformation.

1.4Functionality and Applicability

Unlike traditional metal roofing systems, the design of standing seam panels addresses many common issues such as leaks caused by exposed screws and cracking due to thermal expansion. This type of metal roofing system is suitable for various climates, from rainy temperate zones to snowy cold areas, offering durable protection and a long lifespan.

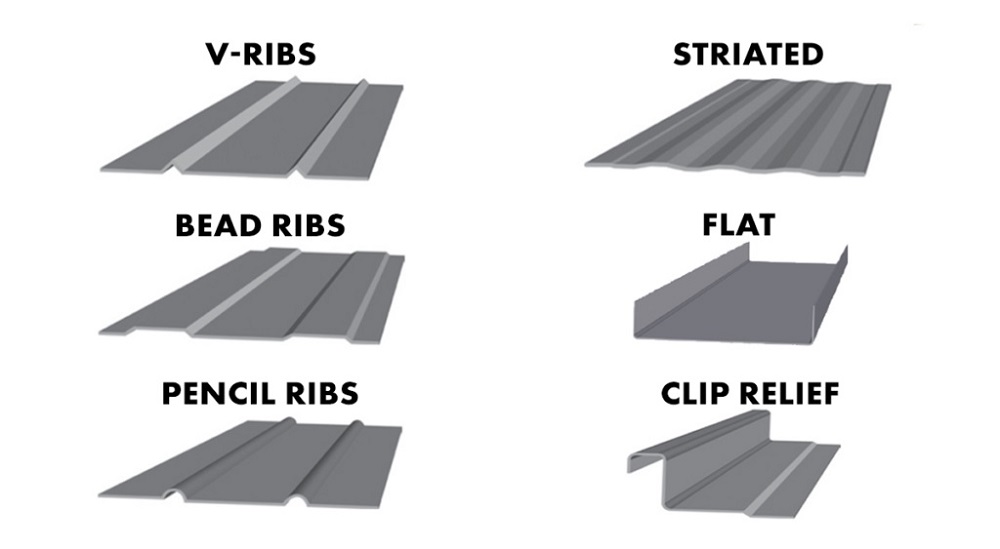

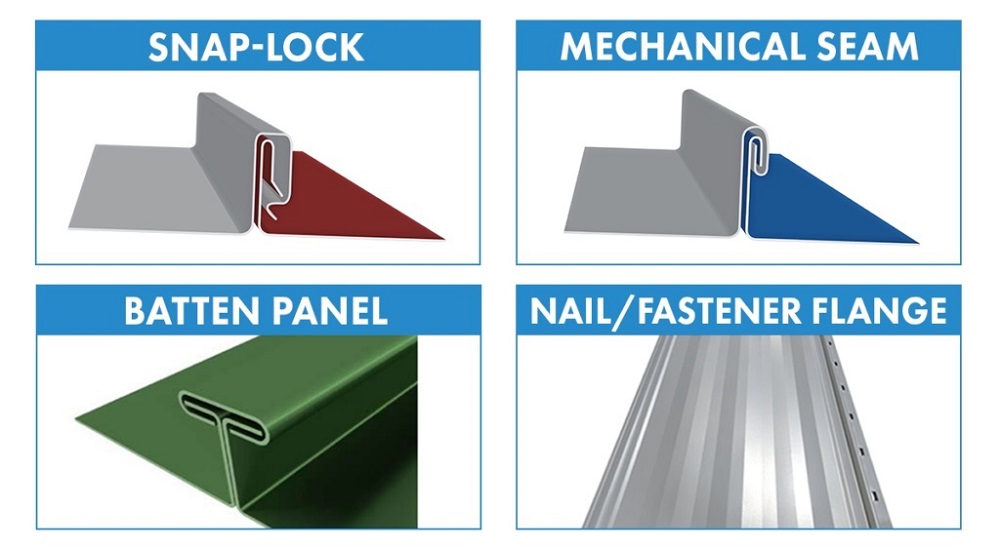

2.0Types of Standing Seam Panel Profiles

- Snap Lock Panel type

Snap lock panels are made by specialized standing seam panel roll-forming machines. These panels have specific edge shapes, with male and female legs that snap together during installation without the need for hand or mechanical seaming. This type is suitable for small to medium-sized buildings.

- Mechanical Lock Panel type

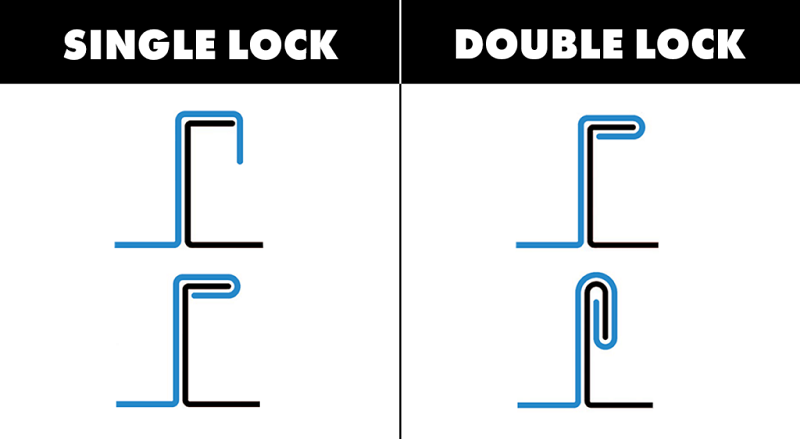

Mechanical lock panels require special tools or machinery to seam the panels together. They typically come in two types: 90-degree single lock seams and 180-degree double lock seams. The double lock structure is more secure and durable.

- Batten Seam Panel type

Batten seam roof systems are created by roll-forming two legs of the panels and then joining them together. A metal cap is placed over the legs to form the seam, and it is either snapped into place or mechanically seamed. There are two common types of caps for batten seam panels: T-shaped seams and snap-on caps.

- Hook Lock Panel type

Hook lock panels are similar to snap lock systems, but instead of using clips to secure the panels to the roof deck, the male leg of the metal panel is directly fastened to the deck. Once the fasteners are in place, the female leg snaps over the entire male leg, concealing the fastener heads.

3.0Advantages of Standing Seam Metal Roofs

3.1Waterproof Performance

- Seam Design:The key feature of standing seam roofs is the raised seam, where panels are securely locked together, preventing water from seeping through the seams. These seams rise above the panel surface, effectively blocking rain and snow.

- Hidden Fasteners:Unlike traditional roofing systems, hidden fasteners reduce the risk of loosening or corrosion from external elements.

3.2Durability

Material Strength: Standing seam metal roofs are typically made from materials like aluminum, stainless steel, and galvanized steel, which can be further treated for enhanced corrosion resistance.

Low Maintenance

- Typically, standing seam metal roofs only require periodic inspection and cleaning, with minimal need for frequent repairs or replacements.

- The smooth surface of metal panels makes them less prone to dirt accumulation, requiring only occasional cleaning.

3.3Ease of Installation

The vertical seams connect the metal panels into a continuous system, reducing the number of seams and simplifying the installation process, thus improving efficiency.

4.0Steel, Aluminum, or Galvanized Steel: Which Material is Best for Your Roof?

4.1Galvanized Steel Roof Panels

- Rust Resistance:Galvanized steel is coated with a layer of zinc to provide rust protection, effectively extending the material’s lifespan.

- Strength:Galvanized steel is strong and suitable for roofing systems that must bear heavy loads.

4.2Stainless Steel Roof Panels

- Corrosion Resistance:Stainless steel offers excellent corrosion resistance, making it ideal for extreme environments. It withstands harsh weather with minimal maintenance.

- Strength and Durability:Stainless steel is highly durable, capable of supporting heavy loads.

4.3Aluminum Roof Panels

- Corrosion Resistance:Aluminum naturally resists corrosion, and its surface is often anodized or coated for enhanced durability.

- Ease of Handling and Installation:Aluminum is relatively lightweight, making it easier to transport, handle, and install more quickly.

5.0Key Factors Influencing the Cost of a Standing Seam Metal Roof

5.1Material Costs

- Type of Metal Panel:Different metal types (e.g., aluminum, galvanized steel, stainless steel, copper) have varying costs. Aluminum is typically more expensive than galvanized steel, while stainless steel and copper are pricier.

- Panel Specifications:Custom-sized panels, colors, and finishes are more expensive than standard options. Panels are often manufactured by a standing seam metal roofing machine, and customization increases costs.

- Additional Accessories:Accessories like waterproof underlayment, sealants, clips, and fasteners also add to the overall cost.

5.2Labor Costs

- Installation Complexity:Installing a standing seam metal roof is more complex, resulting in higher labor costs.

- Roof Structure:The complexity of the roof (e.g., pitch, shape) affects the difficulty of installation and therefore the labor cost.

6.0Standing Seam Metal Roof Colors and Styles

6.1Common Colors:

- Silver Gray

- Charcoal Gray

- Blue

- Green

- Red

- White

- Copper

6.2How to Choose the Right Roof Color:

Architectural Style

- Modern Buildings:Colors like charcoal gray, silver gray, and blue provide a clean, streamlined look.

- Traditional Style:Red and green are suitable for traditional or rural-style buildings.

- High-End Architecture:Copper and other premium colors complement luxury or historic buildings.

Climate Conditions

Warm Climates: White, silver gray, and other light colors effectively reflect sunlight, reducing roof temperature.

7.0Standing Seam vs. Corrugated Metal Roofs: Which is Better?

7.1Design

- Standing Seam Metal Roof:Features vertical seams and panels joined by locks, creating continuous longitudinal seams.

- Corrugated Metal Roof:Panels have noticeable wave-like patterns, typically in a wavy form.

7.2Connection Method

- Standing Seam Metal Roof:Panels are connected with a locking system that forms sealed seams.

- Corrugated Metal Roof:Panels are fixed to the roof frame with screws or nails.

7.3Installation Method

- Standing Seam Metal Roof:The precise connection between panels ensures water-tightness, making the installation process more complex.

- Corrugated Metal Roof:Installation is simpler and suitable for small projects.

7.4Pros and Cons Comparison

Standing Seam Metal Roof

Pros:

- Excellent waterproof performance

- Modern aesthetic

- Low maintenance

Cons:

- Higher material and installation costs

Corrugated Metal Roof

Pros:

- Lower cost

- Simple installation

- Good strength

Cons:

- Weaker waterproof performance

8.0Standing Seam Metal Roof Cost FAQs

What is the average lifespan of a standing seam metal roof?

The average lifespan of a standing seam metal roof is between 40 to 70 years.

Does installing a standing seam metal roof take longer than traditional roofing materials?

Yes, the installation of a standing seam metal roof usually takes longer than traditional materials like asphalt shingles, but the final quality and durability are much higher.

Does the installation of a standing seam metal roof require special tools or techniques?

Yes, the installation requires specialized seaming tools and experienced professional installers.

Can a standing seam metal roof withstand extreme weather conditions?

Yes, standing seam metal roofs have excellent waterproofing capabilities, and the seam design effectively prevents leaks.

Can a standing seam metal roof be installed over an existing roof?

In some cases, a standing seam metal roof can be installed over an existing roof, depending on the structure, material condition, and installation requirements of the existing roof. A professional evaluation is required.

Reference:

https://sheffieldmetals.com/learning-center/standing-seam-metal-roofing

https://www.homeadvisor.com/cost/roofing/standing-seam-metal-roof/