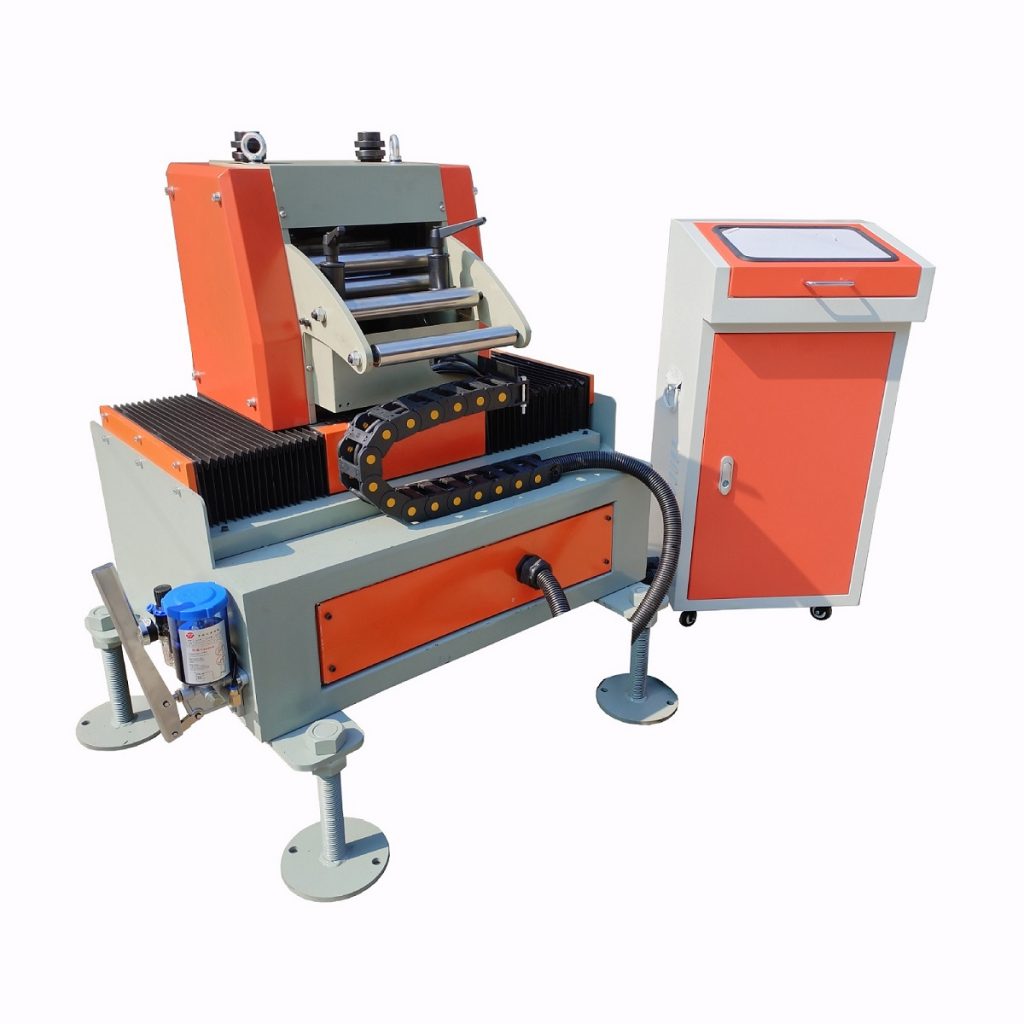

Sheet Metal NC Servo Feeder Key Features

- High Feeding Accuracy: Controlled by a computer closed-loop feedback system, ensuring precision within ±0.03mm. With positioning pins in the die, accuracy can reach ±0.02mm.

- High Speed & Long Stroke Feeding: Supports high-speed operation and long-distance feeding, significantly improving productivity and operational stability.

- Multi-Stage Feeding Function: Up to 20 sets of different feeding lengths can be pre-programmed, each supporting up to 999 punching times—ideal for complex die processing.

- User-Friendly Manual Mo de: Offers 3-level manual speed settings for flexible, accurate control during mold setup and adjustment.

- Smart Operation Interface: Equipped with an intuitive human-machine interface (HMI) for quick and easy parameter setup (feeding length range: 0.1mm – 9999.99mm).

- Efficient Release Mechanism: Available with mechanical or pneumatic release options. The release point is precisely controlled and can be easily synchronized with the press signal.

- Dual Control Modes: Supports both panel button operation and handwheel control for flexible, multi-functional operation.

- Job Memory for Fast Changeover: Built-in memory storage allows users to save and recall settings easily, reducing setup time during production changeovers.

Application of NC Servo Feeder

- NC Servo Feeder for Power Press Line Automation

- NC Servo Roll Feeder for Coil Cut-to-Length and Straightening Lines

- High-Speed NC Servo Feeder for Metal Stamping Production

- Multi-Stage NC Servo Feeder for Progressive Dies

- Precision NC Servo Feeder for High-Tolerance Components

- General NC Servo Feeder for Coil and Sheet Metal Processing Lines

Image of NC Servo Feeder

Structure & Technical Specifications:

- Servo Drive System: Driven by a high-quality brushless servo motor, ensuring fast response and smooth operation.

- High-Sensitivity Encoder: An accurate feedback system ensures precise and stable feeding control.

- Synchronous Belt Transmission: Replaces traditional gear systems to eliminate backlash, reduce wear, operate quietly, and require no lubrication—safe and eco-friendly.

- Integrated Motor Design: The motor is built into the machine body, reducing the risk of damage during transportation or handling.

- Hollow-Type Feed Rolls: Lightweight with low rotational inertia, ensuring quick response and enhanced feeding accuracy.

- RollerMateriall: Made from imported bearing steel (HRC60°), heat-treated, hard chrome plated, and precision-ground for long service life and excellent surface finish.

- Robust Machine Body: One-piece, high-rigidity structure for long-term durability under heavy loads, easy to maintain and highly precise.

- Precision Gear System: Gears are made of 20CrMnTi steel, carburized, quenched, and precision ground to ensure high wear resistance and accurate transmission.

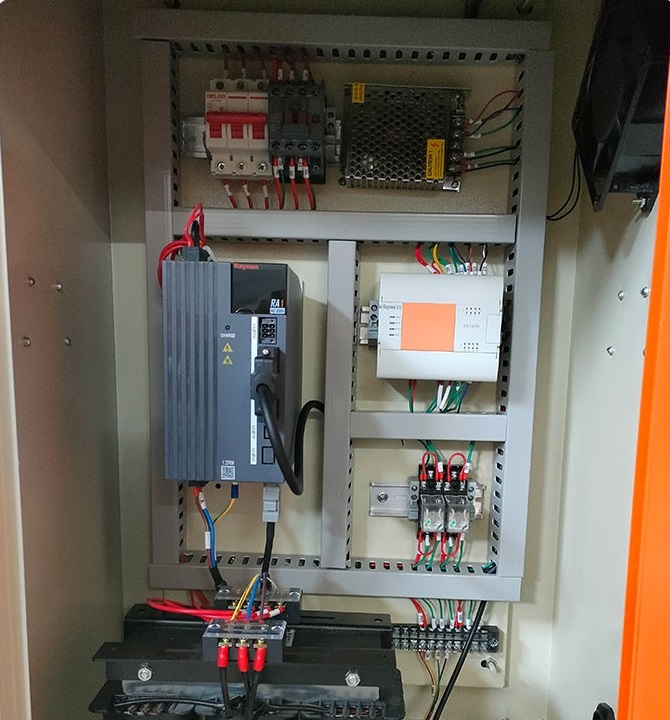

- Advanced Control Electronics: Electrical components are from global top-tier brands such as Siemens, Yaskawa, Mitsubishi, and Schneider—ensuring reliable and efficient performance.

- Flexible Integration: This can be integrated into press lines, cut-to-length lines, or automated feeding systems. Custom solutions are available to suit specific applications.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.