Zigzag NC Servo Feeder — High-Efficiency Solution for Circle Blanking

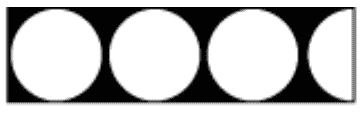

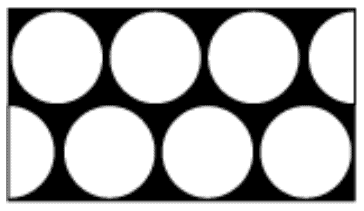

Use a side-to-side shuttling motion to move coil stock over a single blanking die, eliminating the need for double dies. The machine offers a ±5.0″ zigzag movement, providing up to 10.0″ of lateral travel.

Compared to single blanking and straight feeding, the zigzag feeder with double blanking significantly reduces scrap and improves material utilization.

Recommended Line Configuration (for Circle Blanking Production)

- Decoiler & Straightener: For coil loading, uncoiling, and flattening

- Zigzag NC Servo Feeder: For X-Y axis synchronized feeding into press

- Power Press with Die Set: For final blanking. Optional auto-stacking system available for finished circle collection

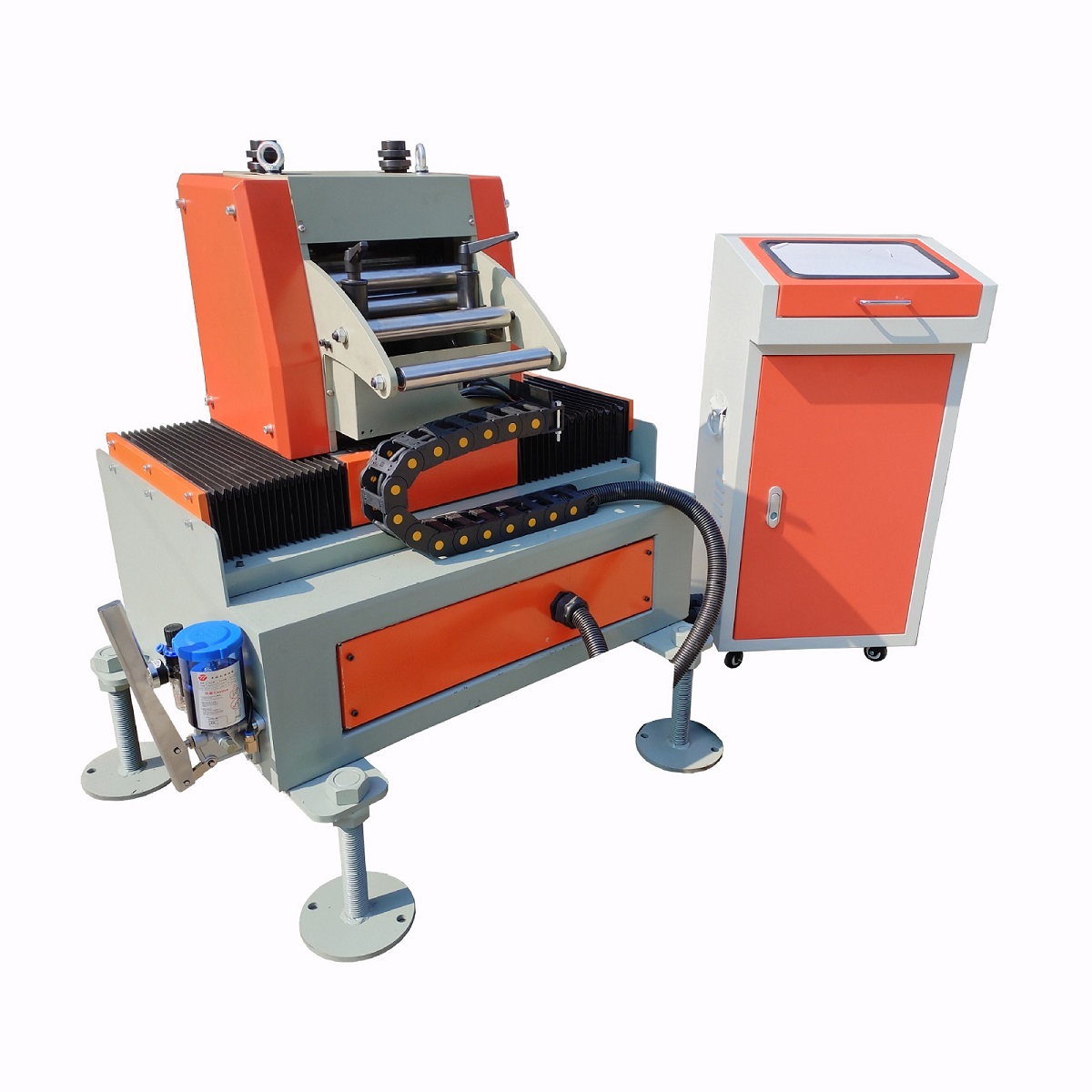

Изображения продукта

Key Features of Zigzag Servo Feeder

- Material Saving: Compared to conventional linear feeding, the zigzag feeding method achieves over 20% reduction in raw material waste by automatically calculating optimal nesting patterns for staggered feeding.

- High Feeding Precision: Equipped with a high-performance AC servo motor and precision gear train, the feeder ensures accurate and stable X-Y axis movement. The lateral shift mechanism adopts linear bearings and ball screws, delivering smooth, low-friction motion with a positioning accuracy within ±0.08 mm.

- Fully Automated Control: Features a user-friendly touchscreen interface that enables automatic parameter calculation and quick setup, minimizing operator workload.

- Compact & Flexible Design: Compact structure with a small footprint, adaptable to various workshop layouts. The system can be either mounted on the press or installed independently in a cabinet format.

- Durable & Reliable Components: Leveling rollers are made from hardened bearing steel with a chrome-plated surface for long-lasting performance. Ball screws and guide rails are made of high-carbon alloy steel, offering high wear resistance and long-term operational stability.

Typical Applications

The Zigzag NC Servo Feeder is suitable for a wide range of stamping applications in the following industries:

- Motor stators and rotors, compressor shells, aluminum blanks, cookware, lighting products

- Home appliances, auto parts, stainless steel utensils, water pumps, heaters, fire extinguishers

- Bearing retainers, filters, clutch parts, brake discs, wheel hubs, electronic shells, and more

Пожалуйста, заполните эту форму, чтобы отправить запрос на предложение. Один из членов нашей команды рассмотрит детали и свяжется с вами в течение 12 рабочих часов.