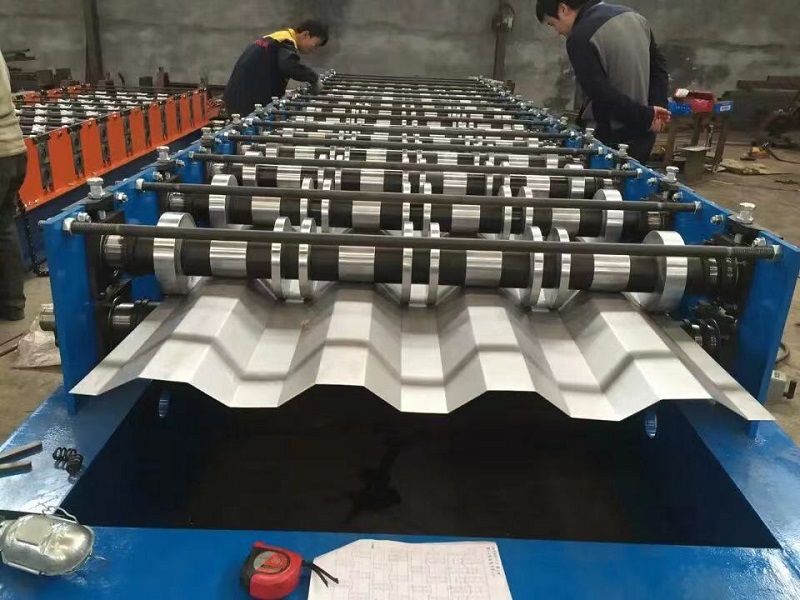

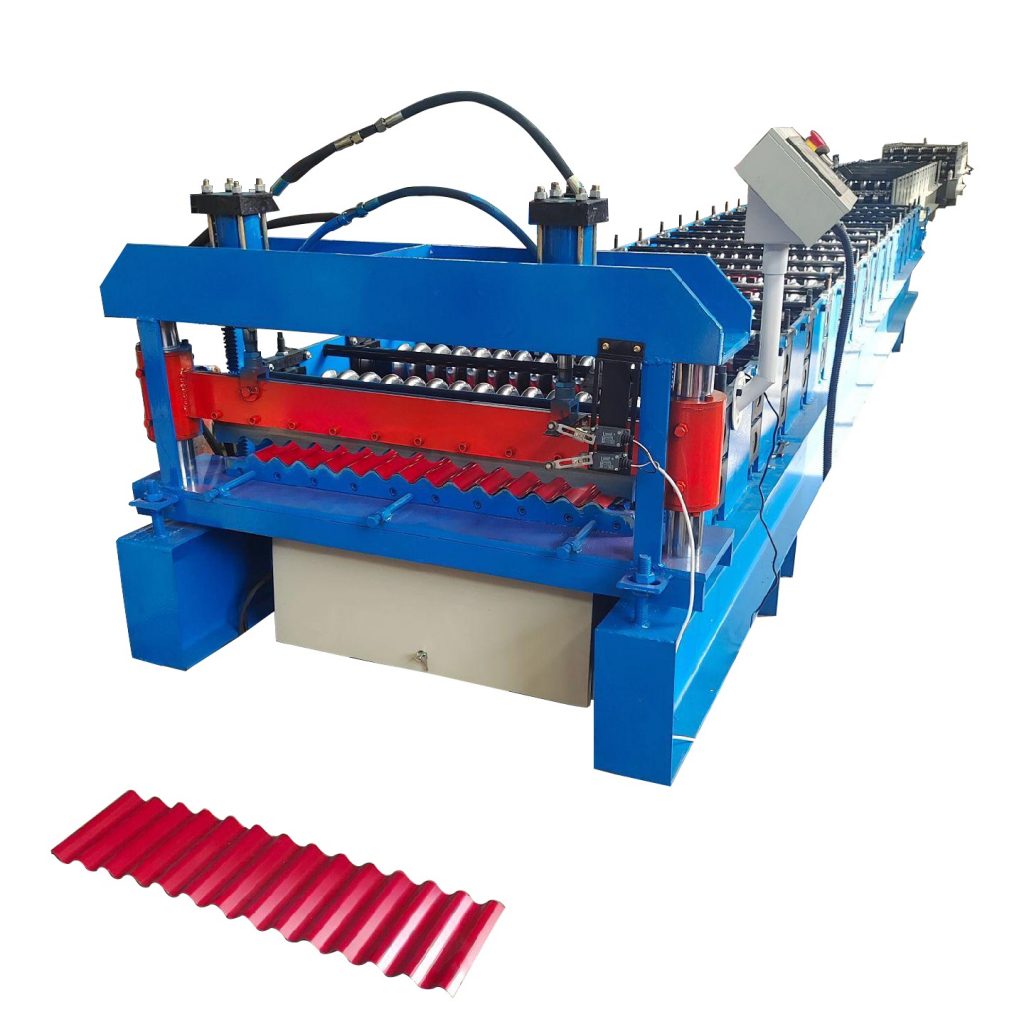

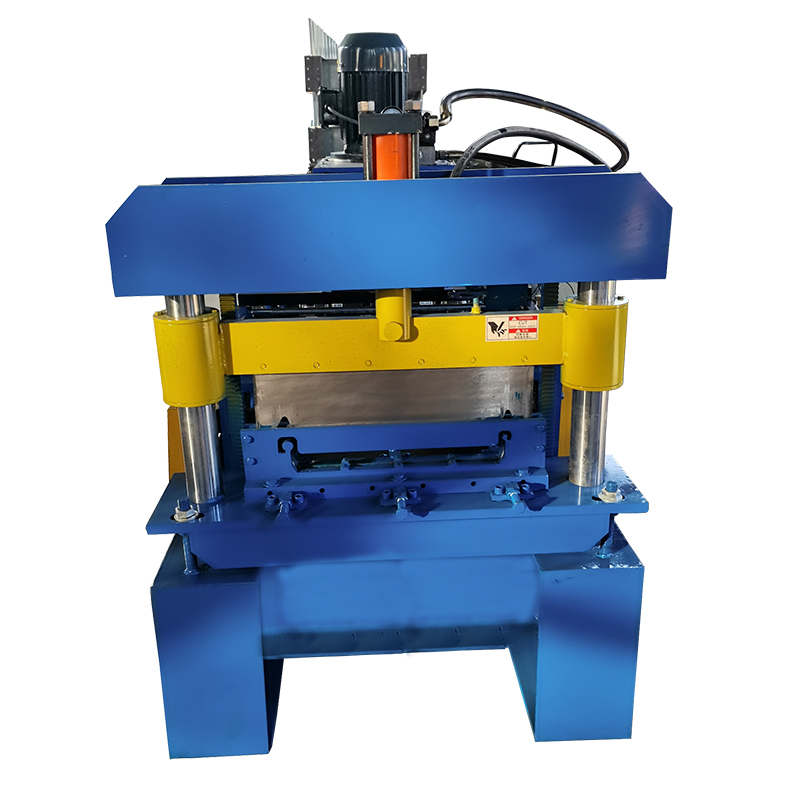

Roof forming machine is a machine used to make roof panels. Its working principle is to process thin and thick materials into the required shape and size through multiple roller pressing.

Feed guide parts: positioning plate, adjust the position of both ends to make it consistent with the feed width; guide frame, play the role of supporting the progressive conveying of the material roll; guide roller, upper and lower round roller design makes the feeding process smoother; hand-pull front shear, manual shearing of the material roll usage.

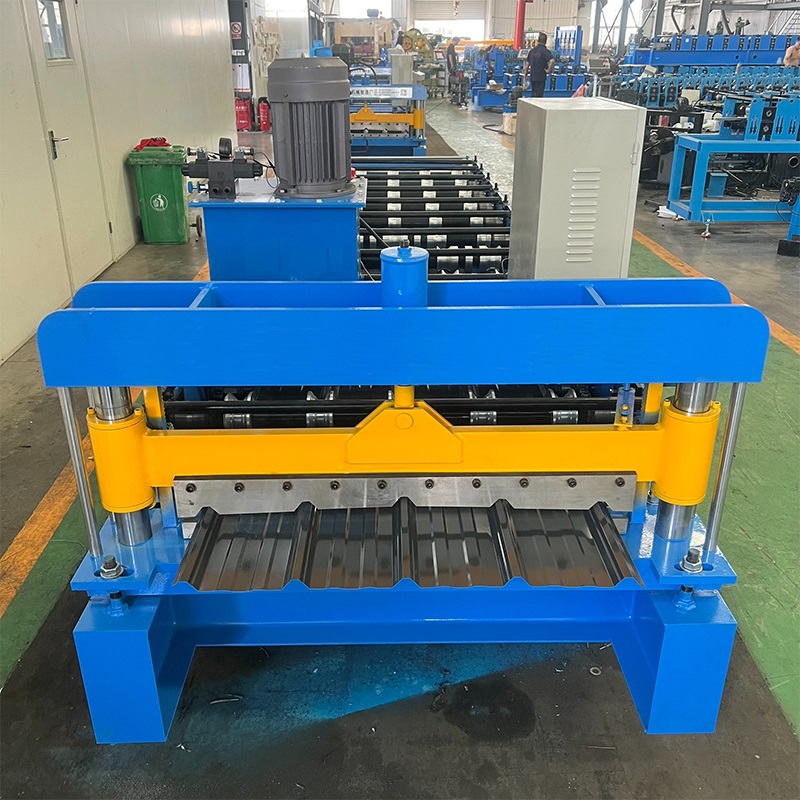

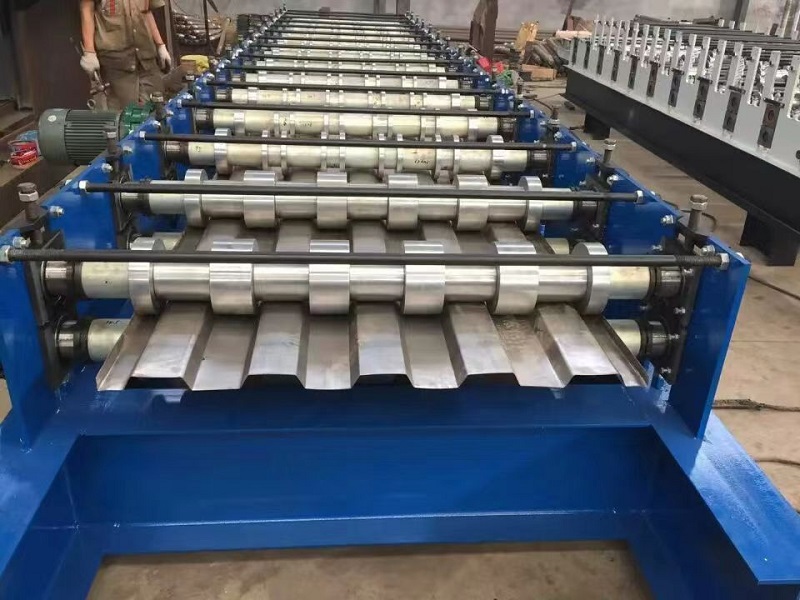

Forming parts: including forming main machine, roller, drive roller, forming knife, etc.

Features of Roof Panel Roll Forming Machine

- Made by high quality mold steel Cr12 with heat treatment

- Cutter frame made from high quality 20mm steel plate by welding

- hydraulic motor:4KW, Hydraulic pressure range: 0-16Mpa

- This machine takes GI/PPGI as raw material, through a series steps and can produce the metal roofing sheets.

- Precise specifications and dimensions can be customized.

- The production speed can reach 25 meters per minute.

- 7.5KW variable frequency speed regulation, with the advantages of strong pressure resistance, good flatness, easy installation, high precision and low processing loss.

Roof forming machine is used for

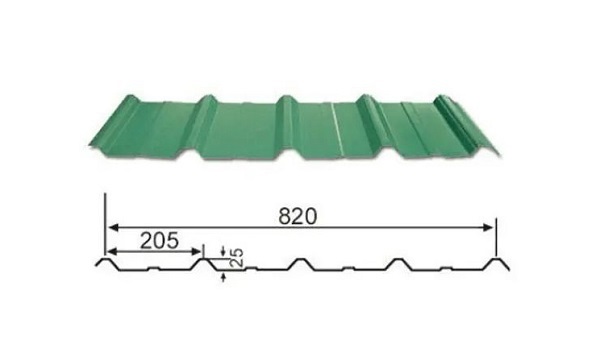

AEK-YX0511

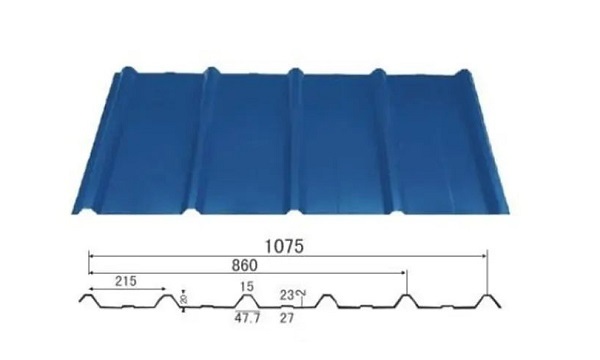

AEK-YX0511 AEK-YX0312

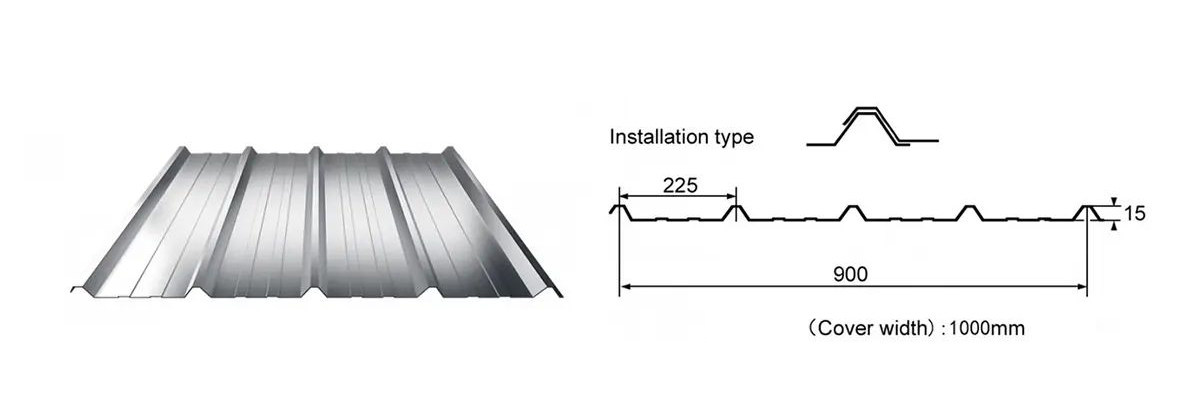

AEK-YX0312 AEK-YX0225

AEK-YX0225Roof panels of different sizes can be customized

High-quality components

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.