Applications

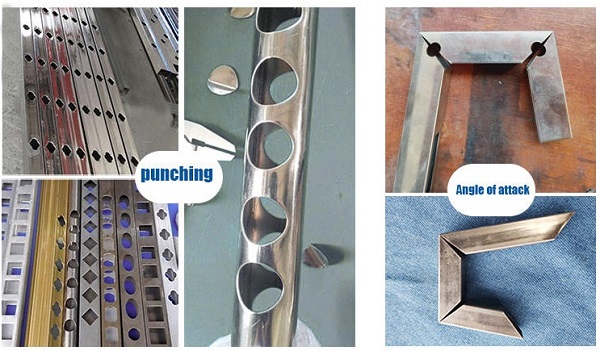

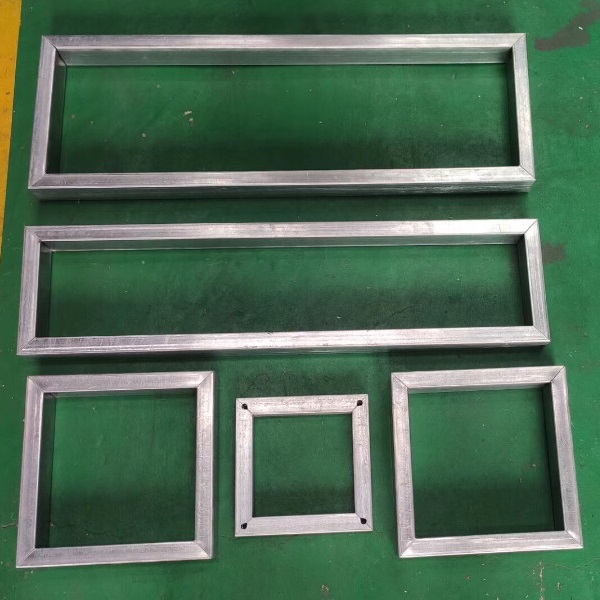

- Door and window manufacturing: In the field of door and window manufacturing, the punching and corner-cutting machine can be used to cut and open holes in the corners of door and window frames for subsequent assembly and installation.

- Manufacturing industry: It can be used to manufacture doors and windows, furniture, auto parts, and other products to realize the automated processing of punching and corner cutting, and improve production efficiency and product quality.

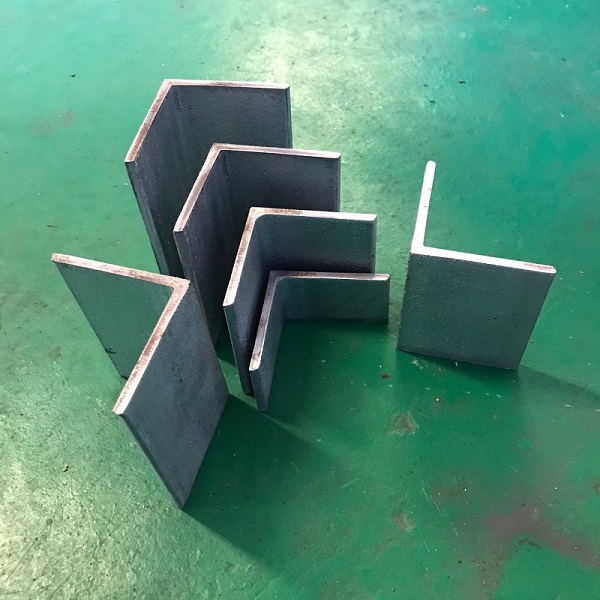

- Construction industry: It can be used for the processing of building steel structures, such as cutting, corner cutting, and punching of profiles such as angle steel and square tubes to meet the needs of construction projects.

- Mechanical processing: It can be used for punching and corner cutting of metal plates, pipes, etc., such as in automobile manufacturing, aerospace, and other fields.

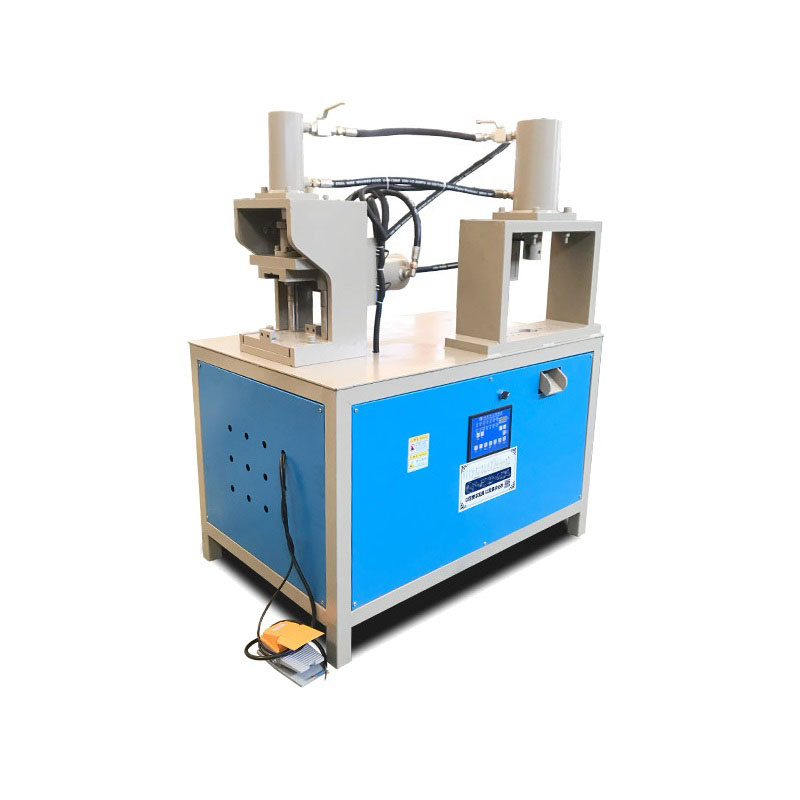

90° /45 °Angle Notching Hole Punching Machine is workable for notching different angles including 30°, 40°, 45°, 60°, and 90°.

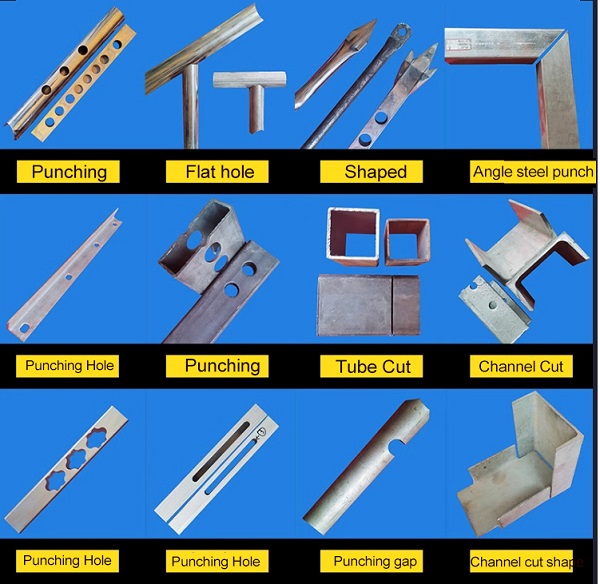

Angle Notching Machine could be designed to combine punching workstation, to perform punching job. 2 in 1 Angle Notching Punching Machine.

Punching and cutting applications

01. Control Panel

Humanized control, multi-function buttons with one-touch switching, clear instructions,

Easy to operate

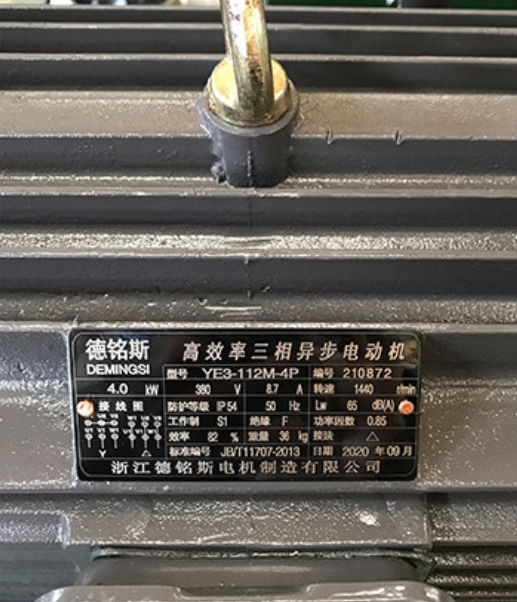

02. Branded motor

All-pure copper branded motor. Equipped with a high-efficiency vane pump, quiet and powerful, escorting your high-speed production

03. Sensor

Full hole and half hole intelligent sensing, high precision, automatic positioning, high efficiency and accuracy of punching

04. Solenoid valve group

Adopts high-precision oil circuit block, fast oil return, low noise, and manually adjustable pressure

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.