$2200.00$2100.00

(Reference Price)

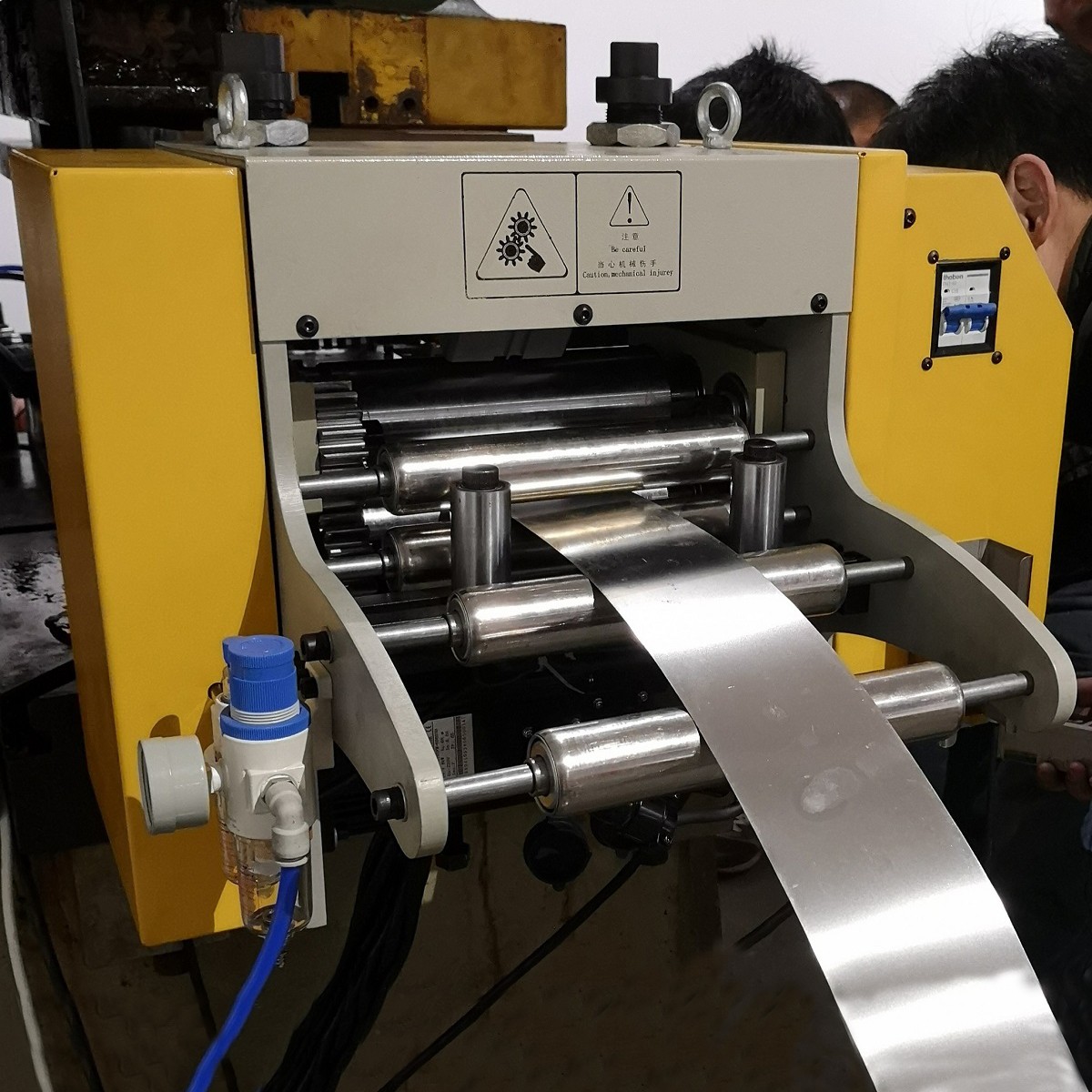

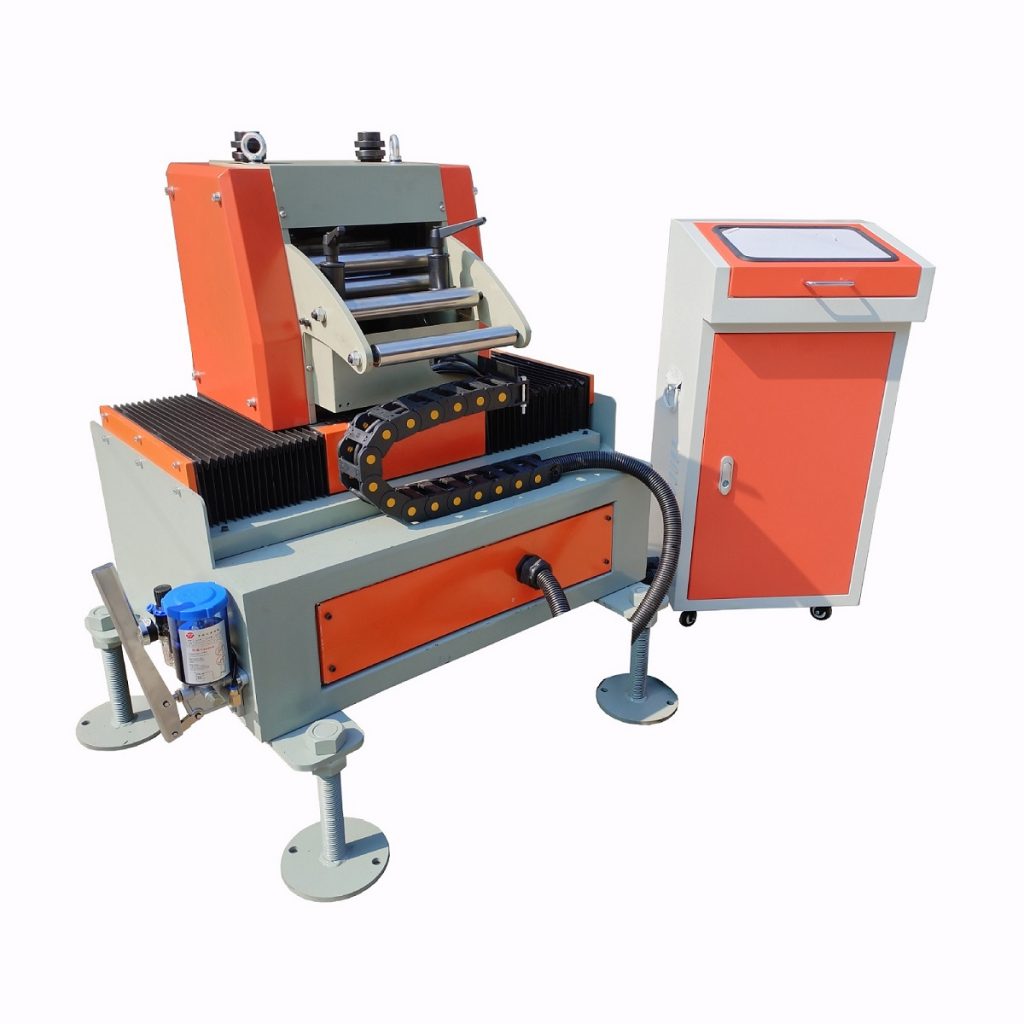

The NC Servo Roll Feeder is an automatic feeding device designed for high-speed, short-pitch feeding and precision processing. It is particularly suitable for high-precision sheet metal processing and punch press coil feeding and is widely used across various industries.

Available with either mechanical or pneumatic release, the feeder offers stable performance and flexibility to accommodate diverse production requirements.

- 3-inch color touchscreen: Easy to operate with a clear, intuitive interface.

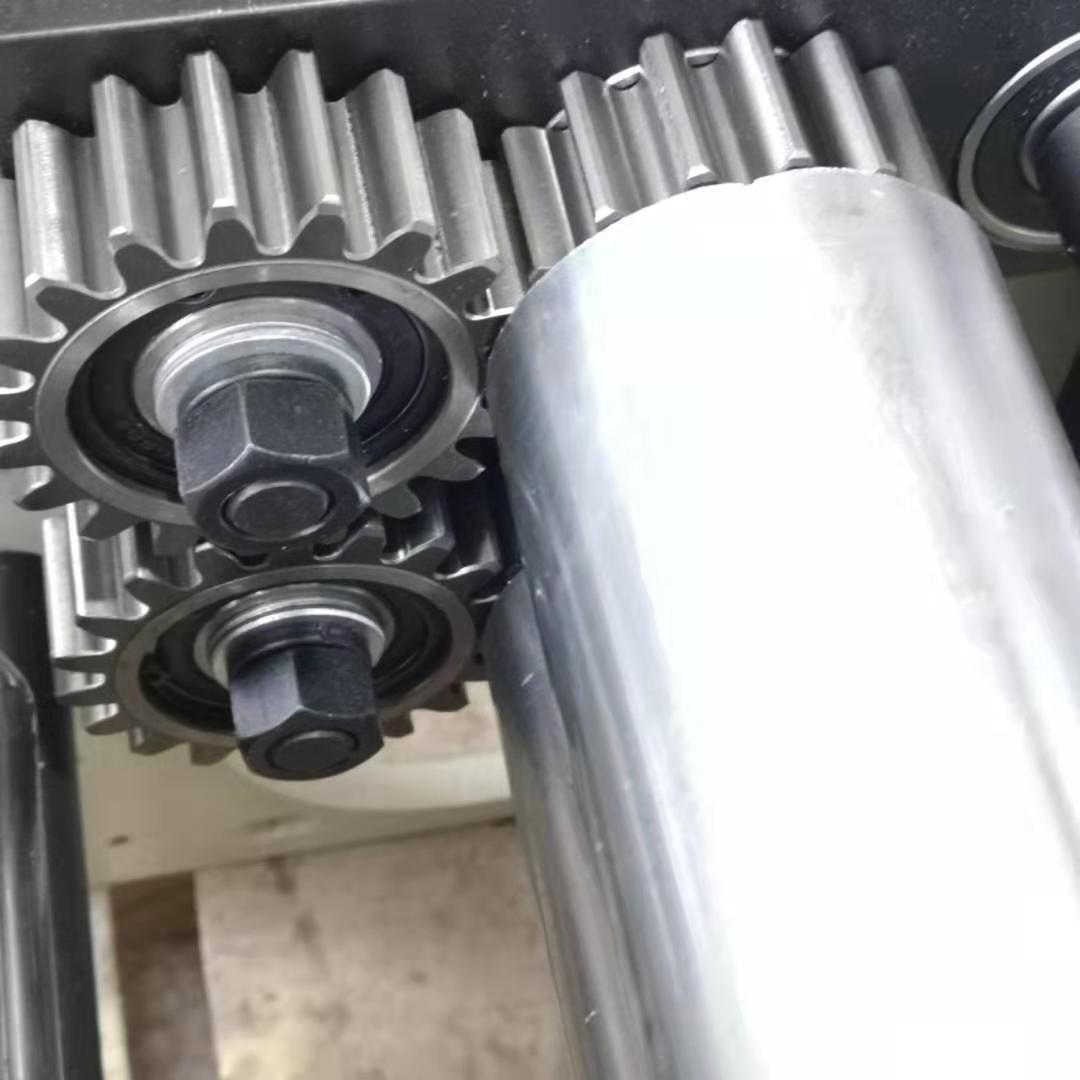

- The closed-loop control system ensures feeding accuracy up to ±02mm.

- Supports up to 999 multi-stage stamping outputs to accommodate various product requirements.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.