This model is a relatively economical solution, the operator manually puts the pipe into the mold, steps on the foot switch, and the machine completes a work cycle.

The operator can change the mold according to the actual production needs, and realize the functions of punching, pipe end grooving, pipe end pressing together, hydraulic cutting off, and so on.

- Most convenient and economical to operate.

- High-quality guide rails and transmission gears.

- Suitable for punching different materials.

- Power is driven by hydraulic pressure and CNC step-less adjustment.

- The hydraulic station has an automatic cooling system

- Multiple punching styles by replacing customized punching machines and dies.

- Durable hydraulic cylinders, and high-quality hydraulic hoses.

- Automatic wiping system to remove metal chips.

- The base of the machine’s punching dies is machined by gantry milling to ensure the high-precision performance of the machine.

- The punching mold is tempered for 48 hours and made of SKD11.

- Our complete machine comes with 24 months warranty.

- Our punching molds come with a 6-month warranty.

Applications

Suitable for different materials: aluminum profiles, stainless steel tubes, mild steel tubes, iron tubes, copper tubes, and so on.

Can punch various shapes of holes: including square holes, rectangular holes, D-shaped holes, triangular holes, elliptical holes, waist-circle holes, prismatic holes, etc.

Suitable for different products: including steel guardrails, aluminum profiles, steel guardrails, zinc steel fences, iron fences, aluminum alloy shelf brackets, handrails, balustrades, and stair handrails.

01. Precision Heavy Duty Cylinder

Self-produced heavy-duty cylinder with stable structure and thickened bore for long service life.

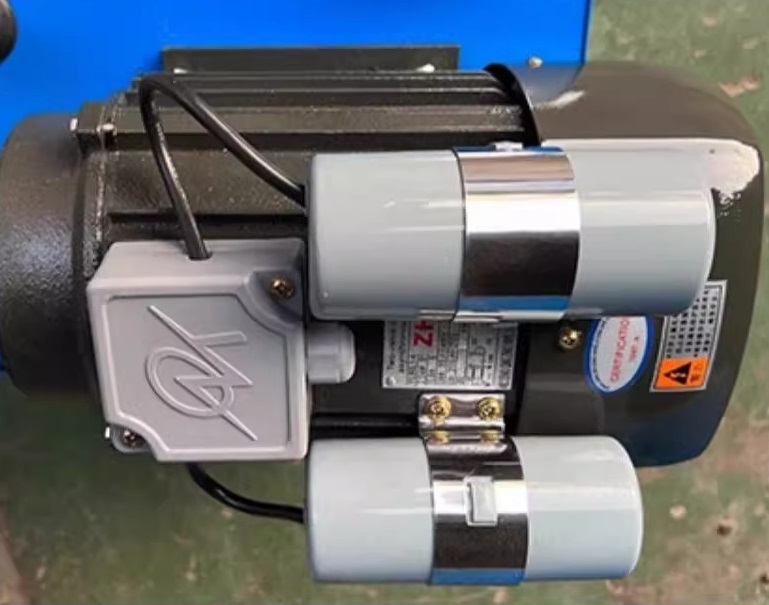

02. All-copper brand motor

Pure copper motor with high static efficiency vane pump is quiet and powerful, high-speed production escort.

03. Simple control panel

Sexualized control, multi-functional keys for one-touch conversion, clear instructions, simple operation

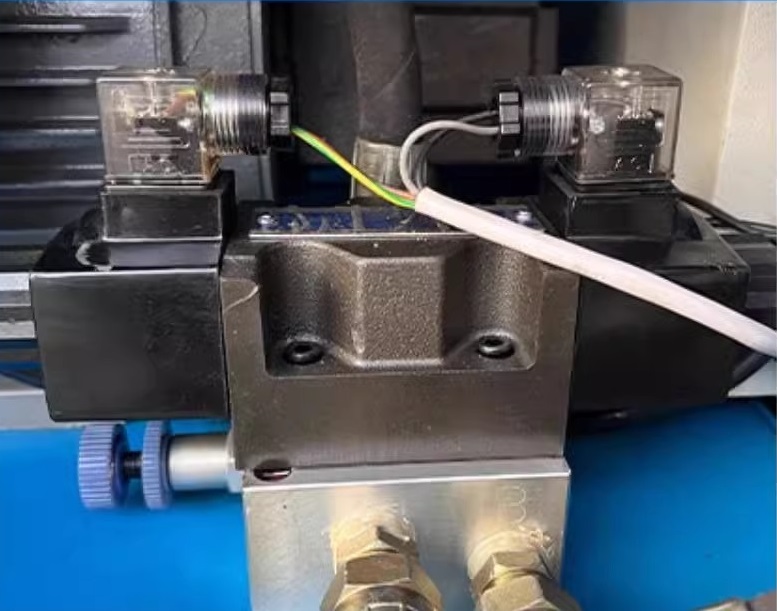

04. Solenoid valve

Adopting high-precision oil circuit block, fast oil return, low noise, and manually adjustable pressure.

05. High-pressure ball valve

The ball valve switch, the switch of the cylinder, is used for controlling and switching the work of several cylinders.

06. Silver Point Pedal

Silverpoint speed control pedal, 3C certification brand, touch-sensitive, kill-the-market pedal.

Mold Replacement

Hydraulic punching machines incorporate single or multiple cylinders with punch and die sets, which can be used in different combinations as required.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.