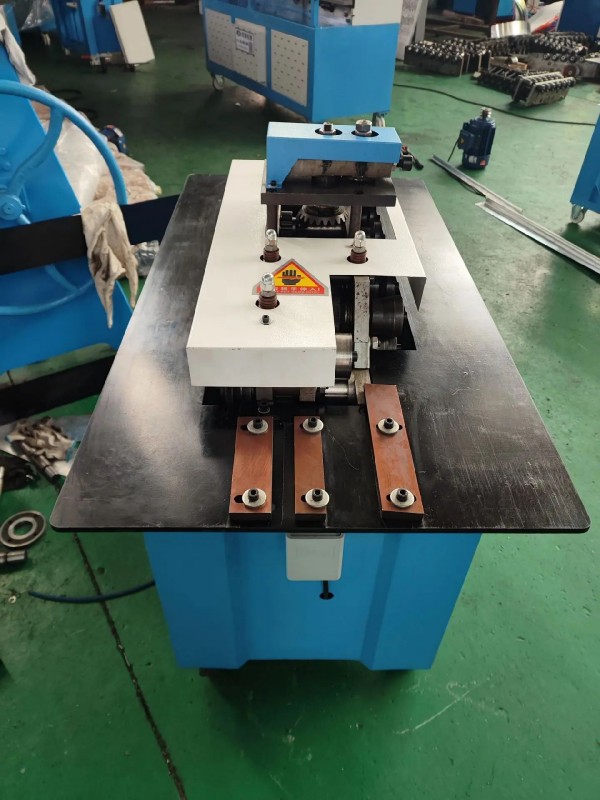

Pittsburgh Lock Forming Machine- Features:

- Material Usage: Each forming cycle uses approximately 1″ of material.

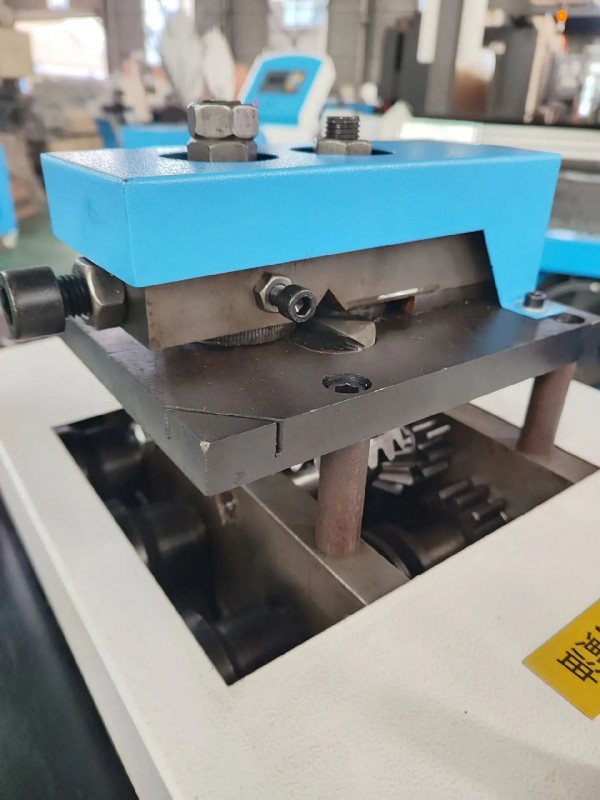

- Adjustable Auto-Guides: Allows for flexible adjustments during operation.

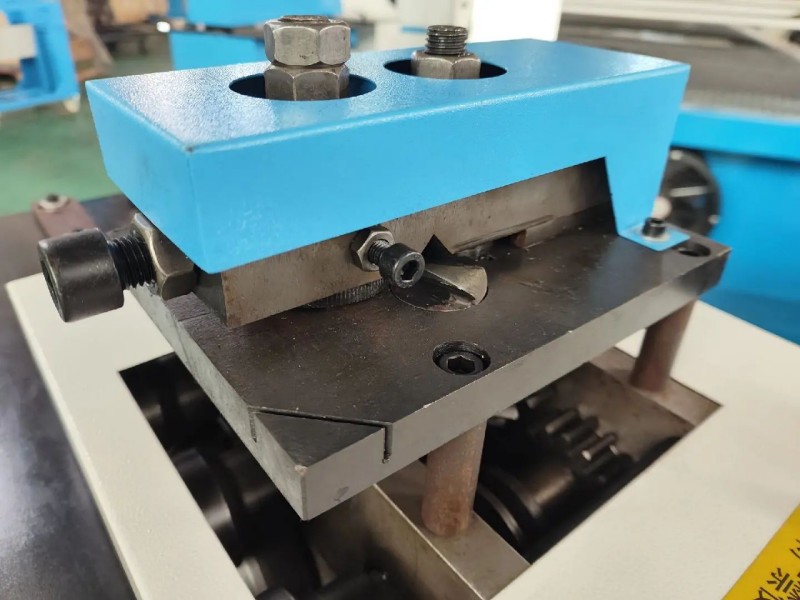

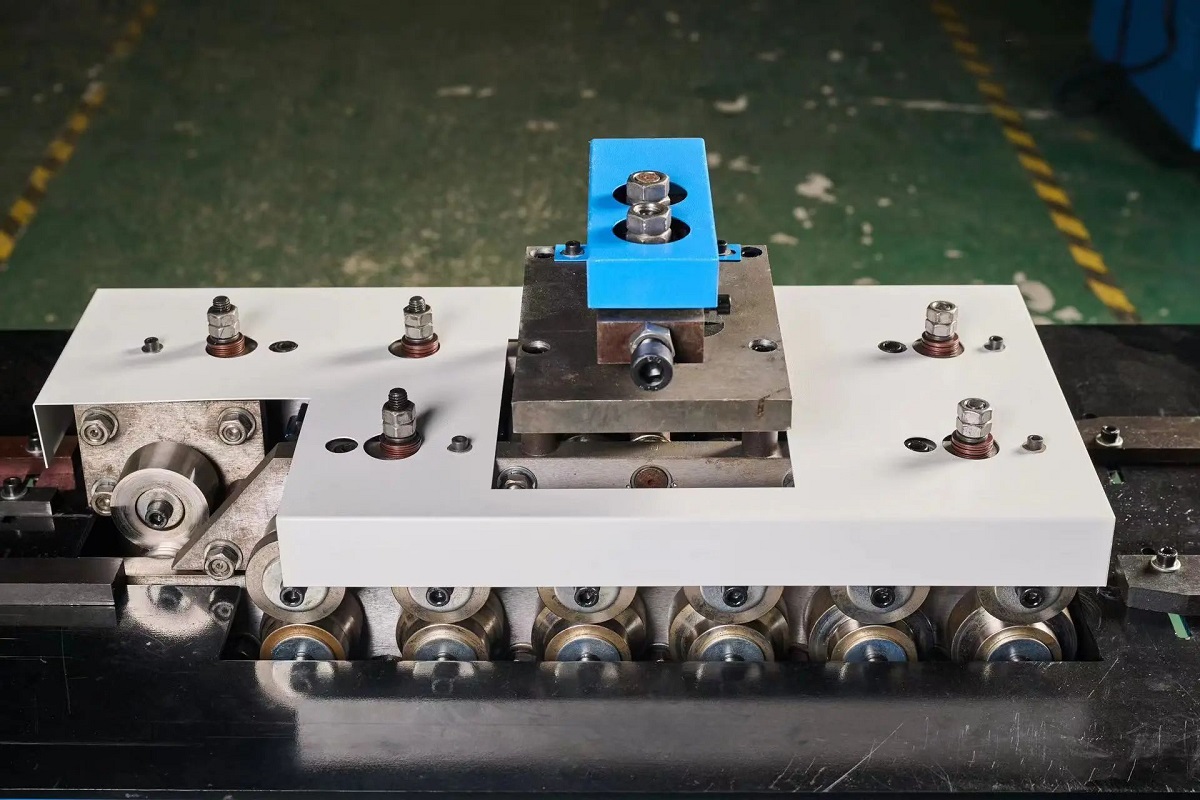

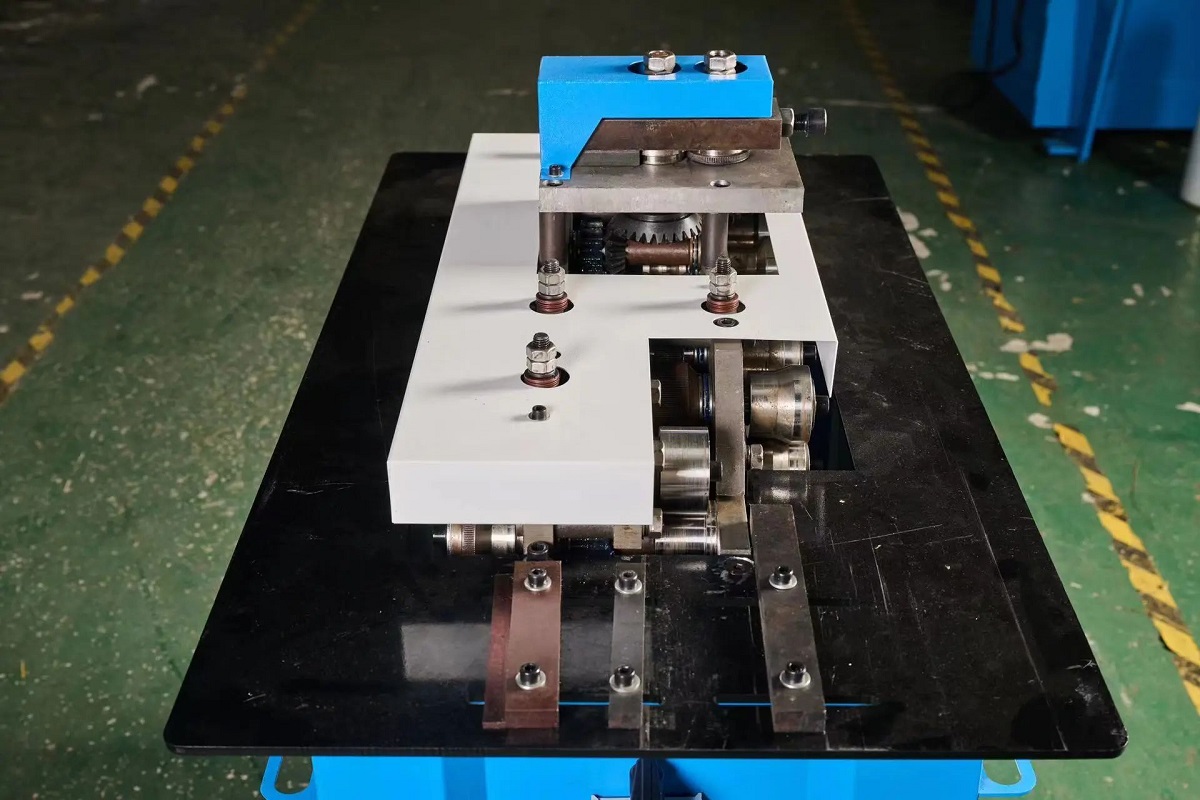

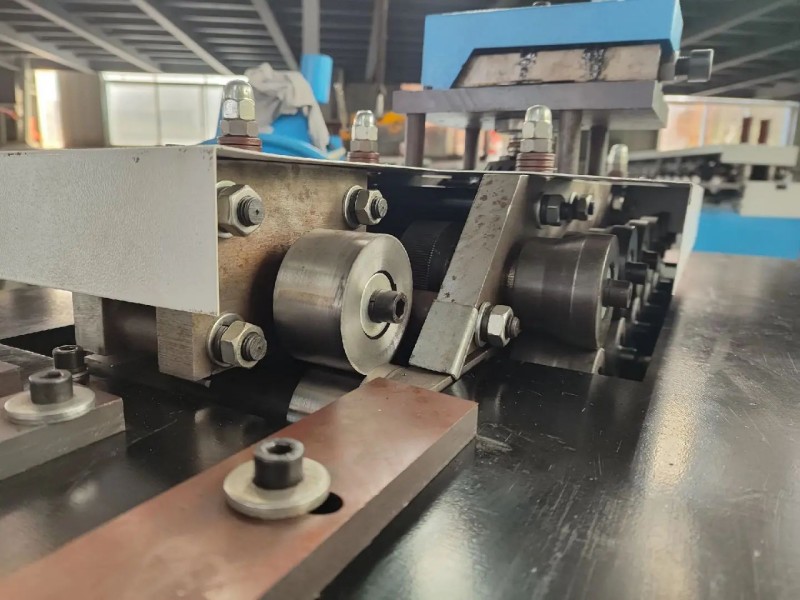

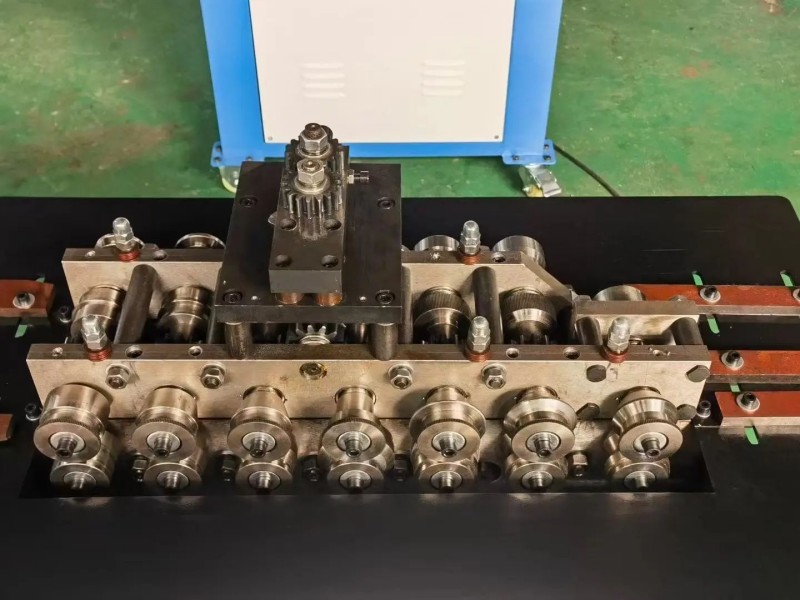

- Durable Forming Head: Constructed with all-steel components and hardened ground shafts for long-lasting performance.

- Steel Forming Rolls: Case-hardened with matching cut gears and needle bearings for smooth, consistent operation.

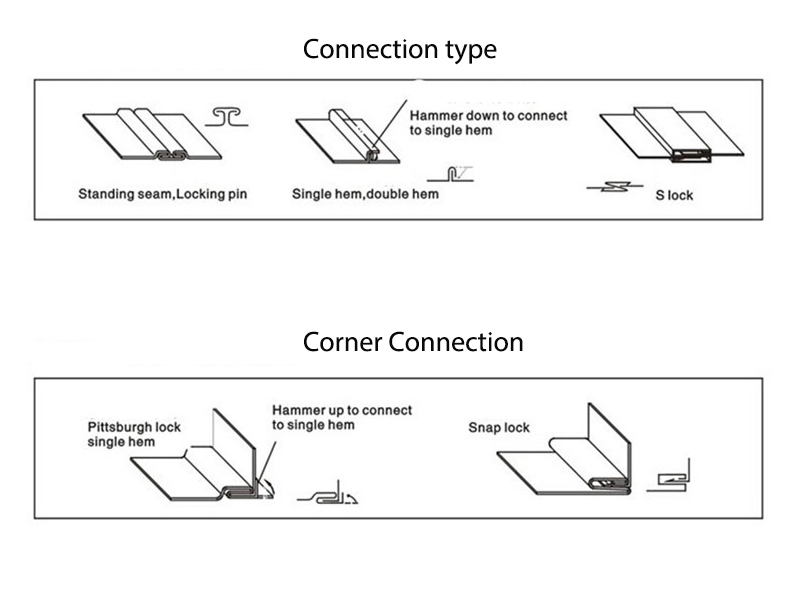

- Pittsburgh Joints: Specifically designed for making Pittsburgh joints in sheet metal, widely used in HVAC ductwork.

- Custom Ductwork: Ideal for producing custom ducts and fittings in HVAC applications.

- Flange Attachment: Provides a flange for easier installation and fitting of Pittsburgh joints.

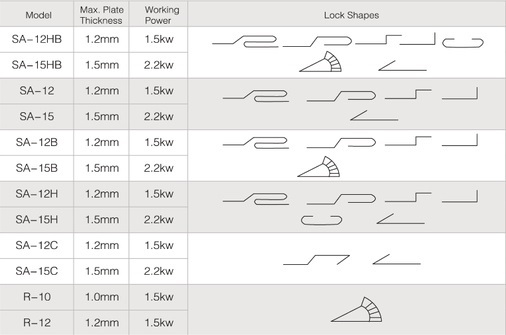

Roll Forming Capabilities:

- Pittsburgh Joint: Max. 16 gauge / Min. 18 gauge mild steel, Thickness: 1.2mm–5mm.

- Flange Attachment: Max. 20 gauge mild steel, Thickness: 1mm.

- Right Angle: Max. 16 gauge / Min. 18 gauge mild steel, Thickness: 1.2mm–5mm.

- Double Seam: Max. 16 gauge / Min. 18 gauge mild steel, Thickness: 1.2mm–5mm.

- Drive Cleat: Max. 20 gauge mild steel, Thickness: 1mm.

- Z-Shape: Max. 16 gauge / Min. 18 gauge mild steel, Thickness: 1.2mm–5mm.

Specifications:

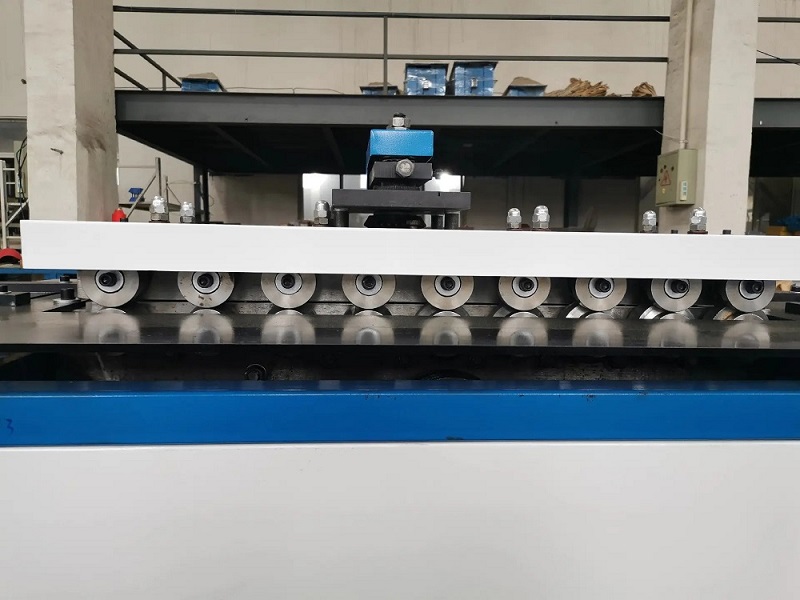

- High-Quality Alloy Steel Rollers: Made from premium alloy steel, heat-treated for high hardness and wear resistance, capable of withstanding 2,500 hours of continuous operation.

- Powerful Motor: Equipped with a 220V 1500W pure copper coil motor, offering strong power, high durability, and low power consumption for extended use.

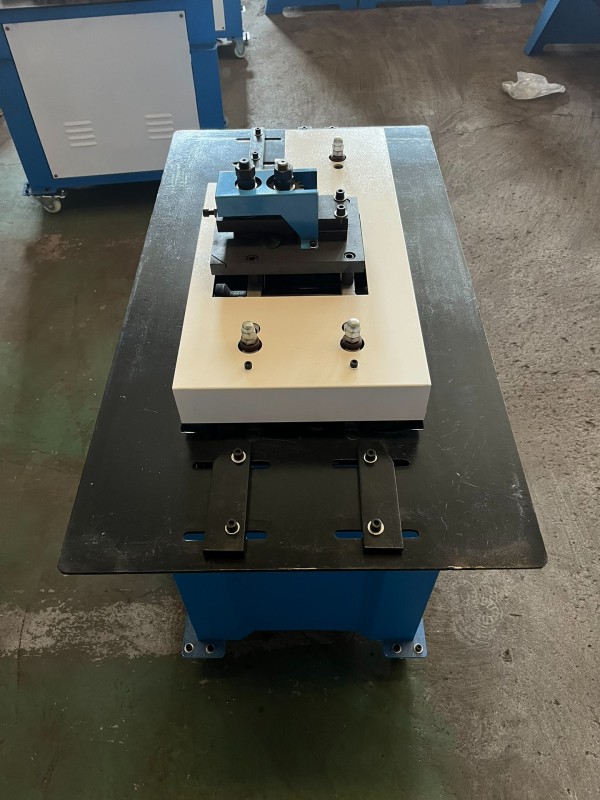

- Portable and Mobile Design: Features high load-bearing, wear-resistant universal wheels, making it easy to move and suitable for various work environments.

- Precise Planishing Required: To ensure optimal seaming, pre-planishing the metal sheets is recommended for more accurate results.

- Versatile for HVAC and Sheet Metal Applications: Perfect for processing square and rectangular ventilation and exhaust pipes, with a compact design for easy transport and operation.

Advantages:

- Long Service Life: Designed with high-strength materials and ball bearings to ensure durability and longevity under continuous operation.

- Stable and Convenient Operation: Features a user-friendly design that guarantees stable performance, making it ideal for various production environments.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.