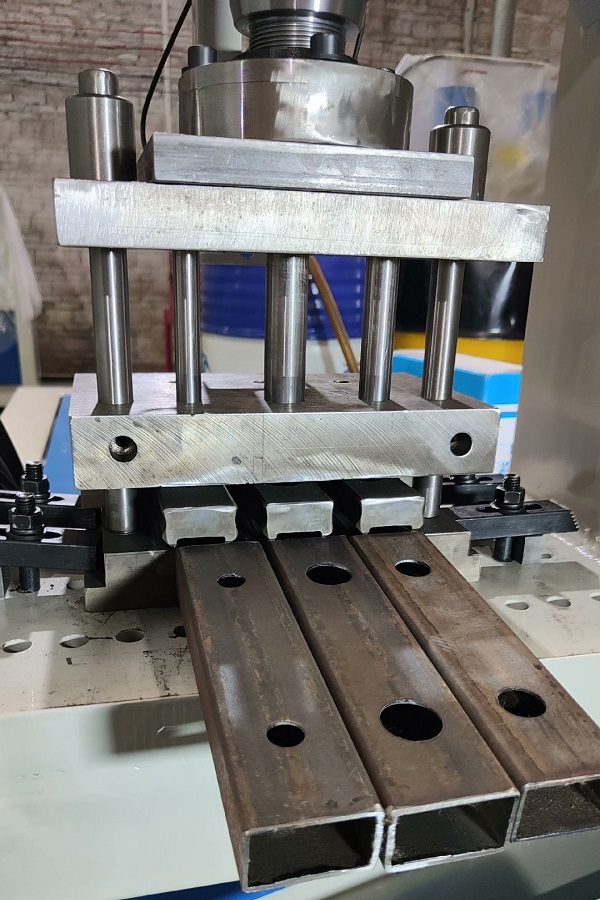

- Many molds can be installed on one machine, some up to more than 10 sets of composite molds, no need to go back and forth to change the molds frequently.

- Equipped with computer control and touch screen control, it can realize single or multiple station work, and selective station work, very convenient to use.

- Compared with the traditional table drill, it solves the shortcomings of table drill drawing line punching with burrs, pits, and pipe deformation.

- The equipment has a four-volt trolley automatic feeding, hole distance precision system, and simple, convenient, and efficient operation.

- Driven by a hydraulic system, the punching, cutting, embossing, and other processing operations are carried out on metal plates through the punching head, which is suitable for the processing of various metal plates, such as aluminum plates, stainless steel plates, and so on.

- The multi-station design allows the punching machine to carry out multiple processes at the same time, avoiding the tedious process of a traditional single-station punching machine that requires multiple operations, saving time and labor costs.

Pipe punching machine video

Pipe punching machine die switching

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.