Drilling and milling machine Machine Advantages:

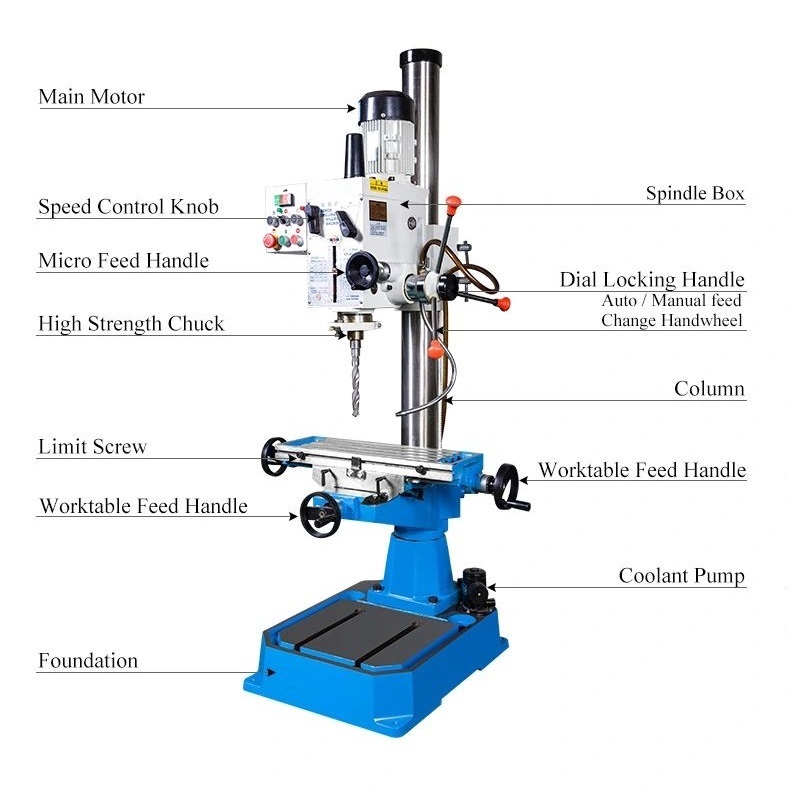

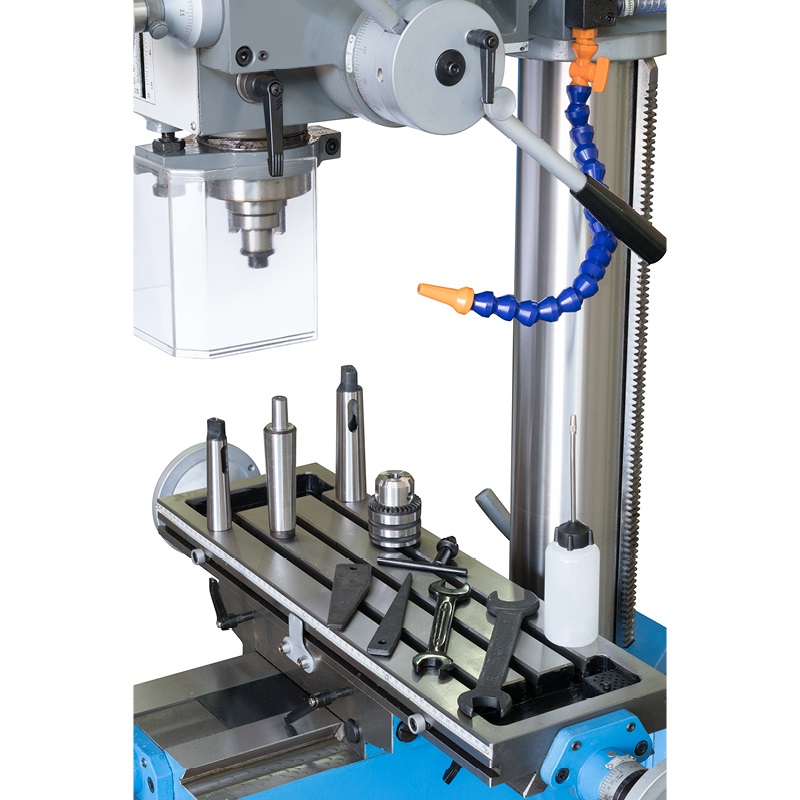

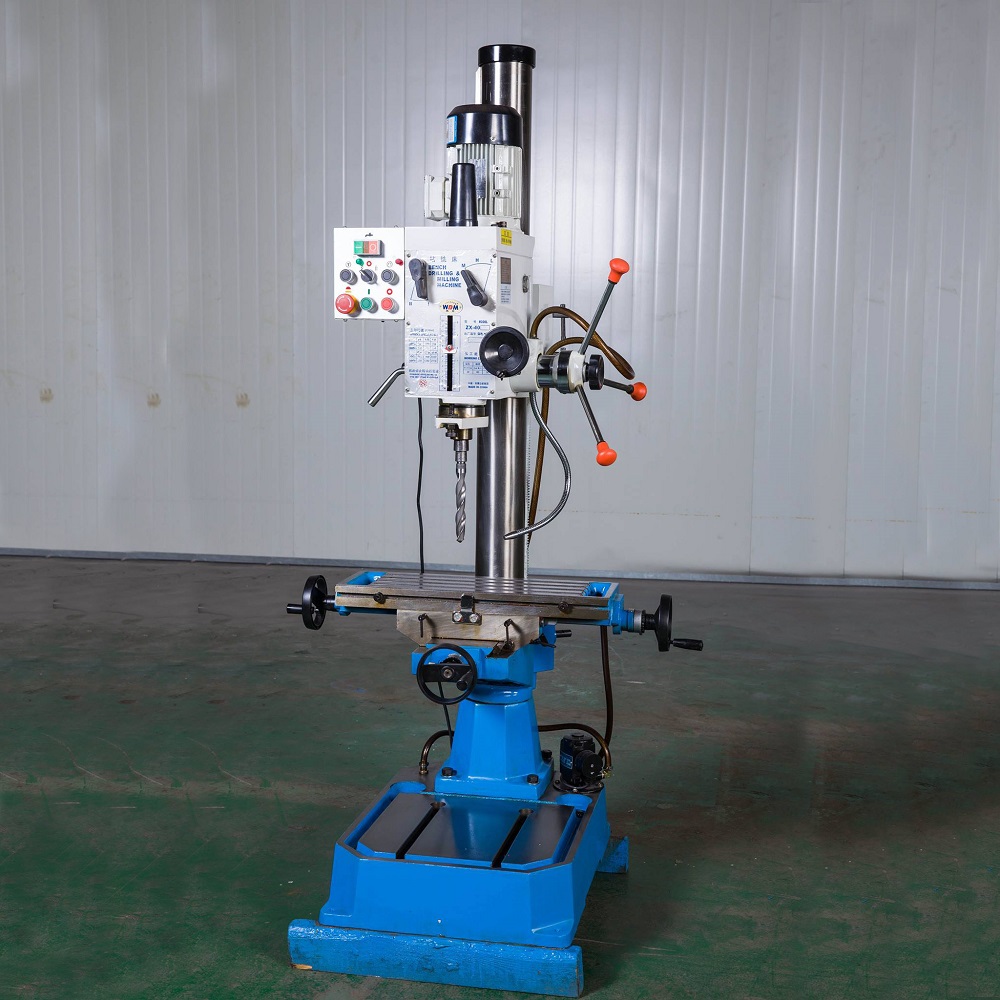

Spindle Box: The spindle box can be operated manually or with fretting. It supports high torque gear transmission, making it ideal for drilling, reaming, and tapping various common materials.

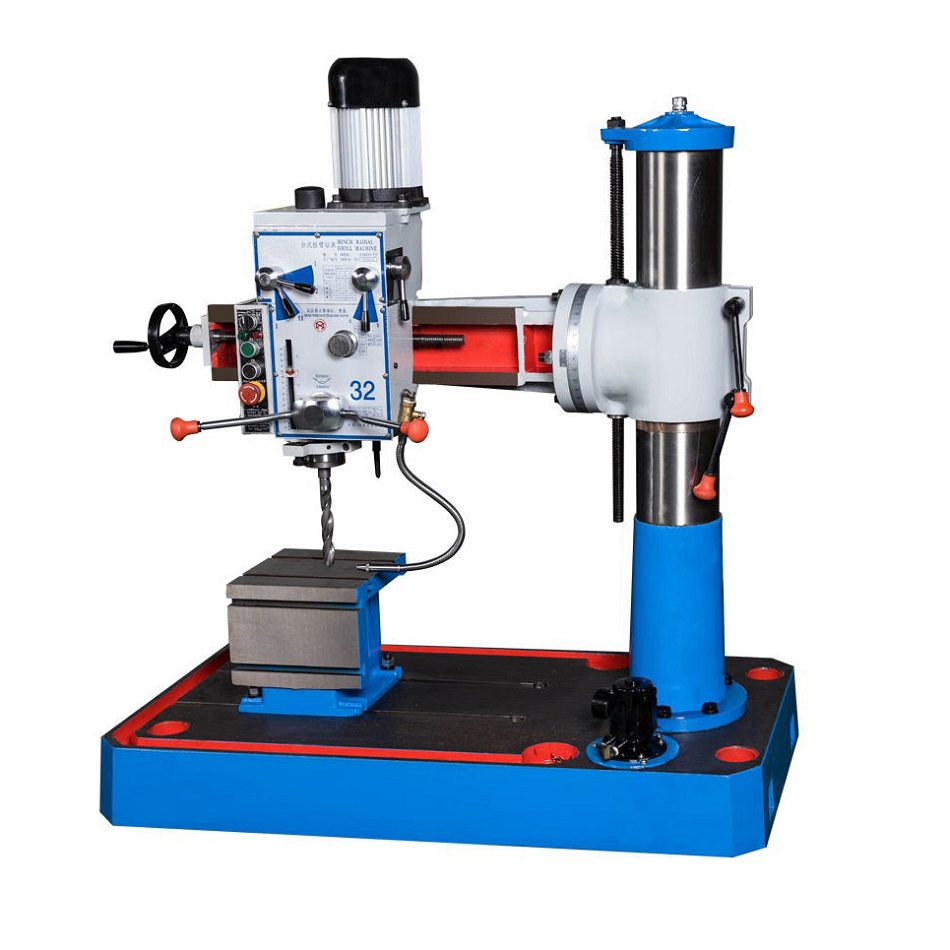

Flexible Spindle Box: The spindle box can rotate 360° and tilt ±45°, making operation easier and more versatile.

Geared Head Drilling & Milling Machine Applications:

- Gear Machining

- Aluminum Machining

- Steel Tapping

- Steel Expanding Milling

Features

- To obtain different hole distances, simply adjust the distance between the spindles of the multi-spindle head, eliminating the need for multiple jigs and reducing production costs.

- The machine can work with an air jig for quick fastening, which significantly improves efficiency by saving both time and energy.

- The table’s lengthwise travel is automatically fed by air pressure, saving time and energy while improving efficiency.

- It can process multiple holes, drilling, reaming, enlarging, and tapping holes of varying distances, diameters, and quantities.

- The adjustable multi-spindle head offers a wide range of hole distances, and the number of spindles can be customized based on customer requirements.

- There is no need to reinstall the workpiece for tapping after drilling. Simply pull the table, and the workpiece moves to the tapping spindle position for tapping.

- The machine can process multiple holes with the multi-spindle head based on customer demands or can drill, ream, and tap a single hole without using multi-spindles.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.