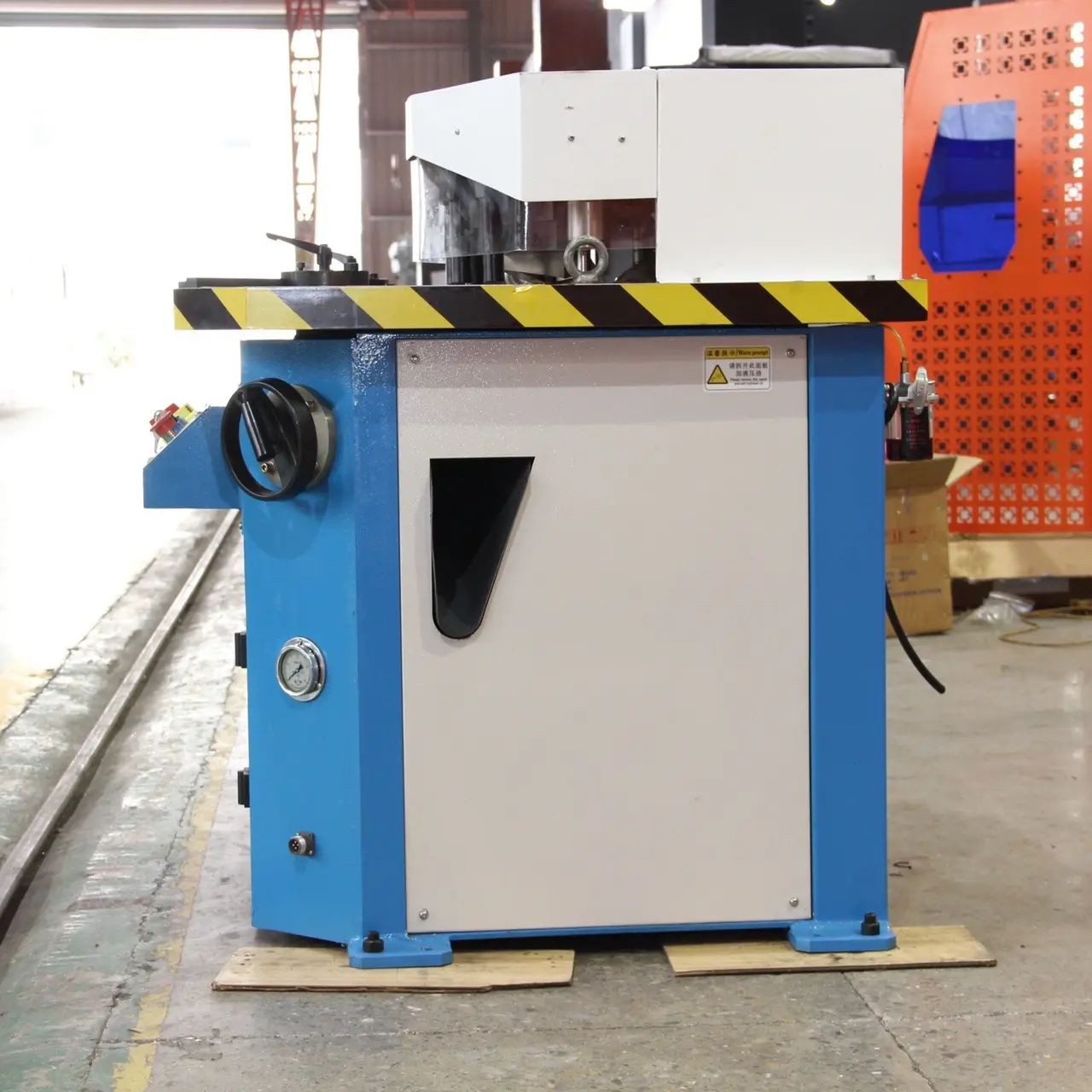

The ALEKVS Hydraulic Sheet Metal Notcher features a large 27” x 23.5” table for precise cuts, powered by a durable full copper motor for efficient performance.

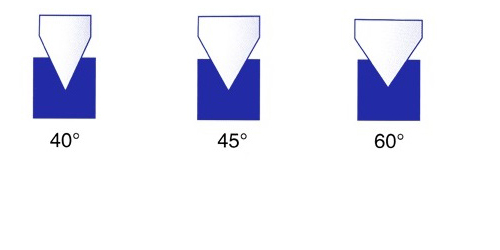

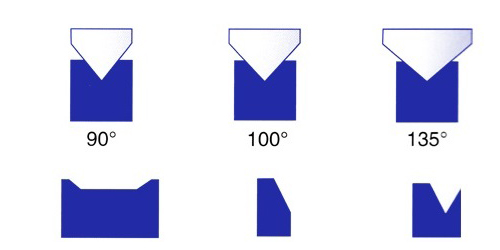

With adjustable angles (40° to 135°) and high-carbon steel blades, it offers versatile and precise cutting, making it ideal for various sheet metal applications.

Hydraulic Corner Notching Machine Features:

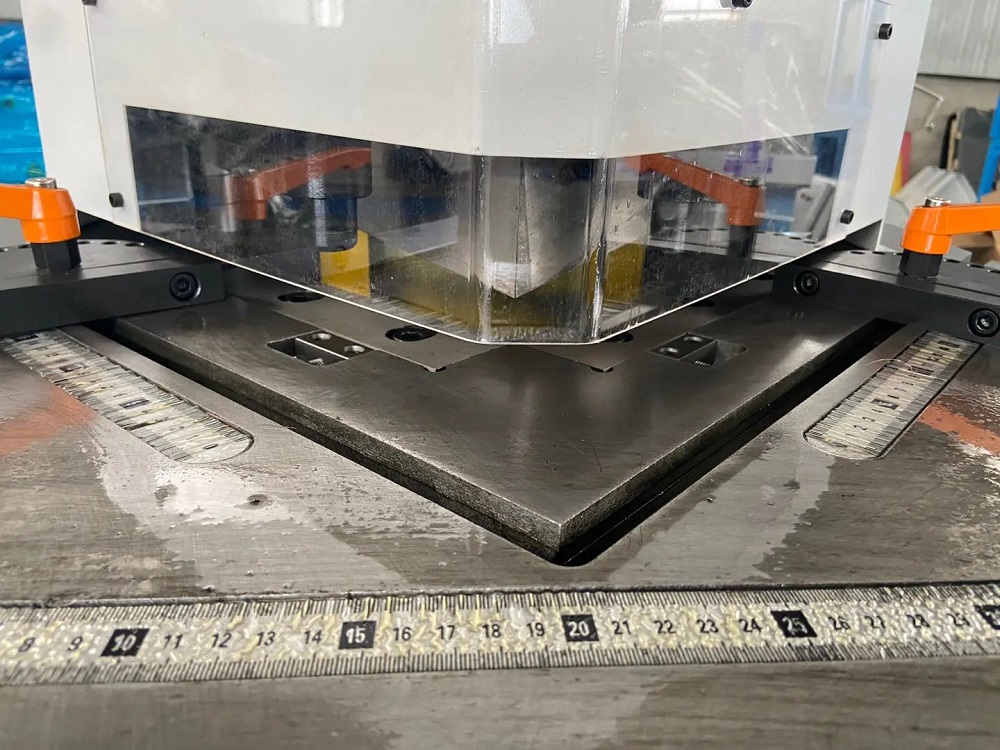

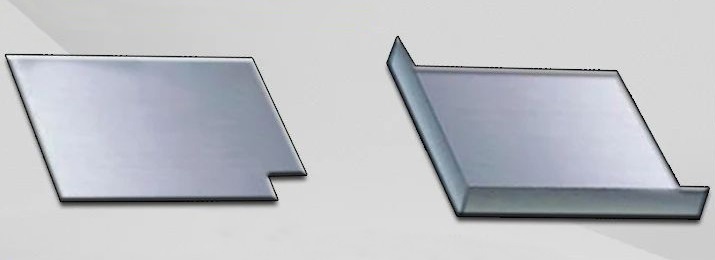

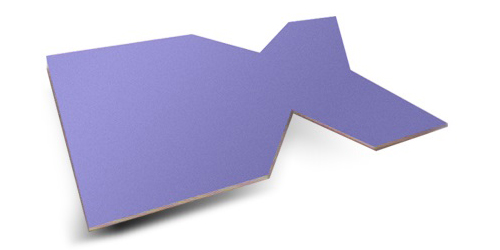

- Large Table Size: The oversized 27” x 23.5” table comes with table guides and miter blocks, ensuring precise notches with every cut.

- Drive: Full copper motor(3-5.5KW), low failure rate, low power consumption, thick copper plate welded body, stable.

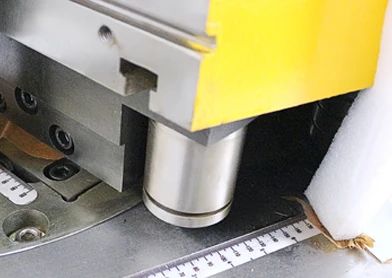

- Blades: Forged high-carbon steel, four cutting edges, full-body quenching, 7,000 cuts per edge.

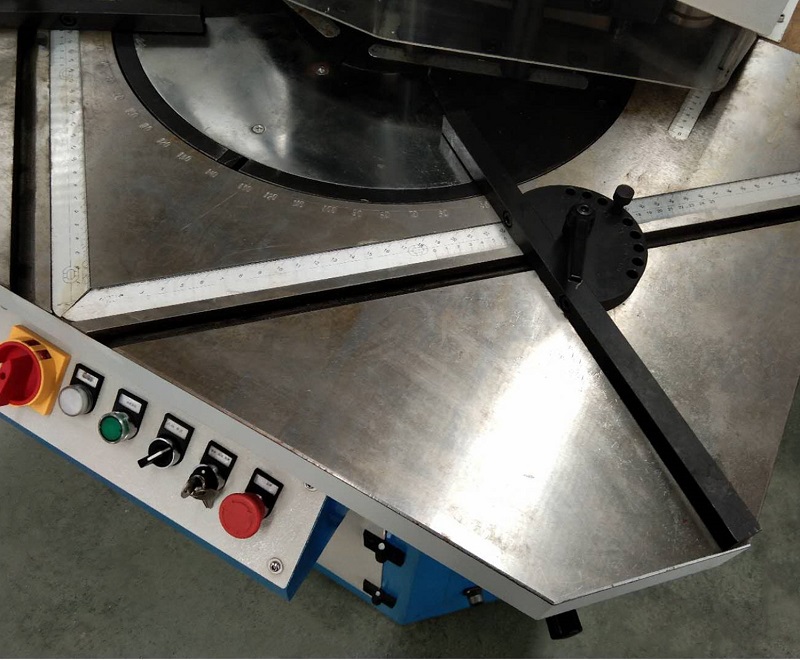

- Adjustment: XY-axis adjustable back gauge, adjustable positioning device, single screw tightening, easy angle and size adjustment.

- Angle Range: Adjustable from 40° to 135°.

- Positioning: Positioning ruler for accurate cutting dimensions.

- Blades Material: High-chromium steel blades, custom non-standard blades available.

- Operation: Multi-function button for blade clearance adjustment, improves efficiency, reduces labor intensity, low noise.

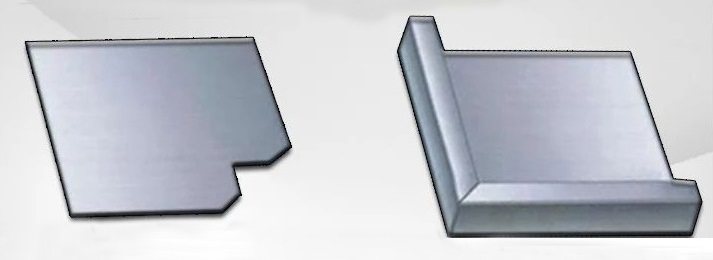

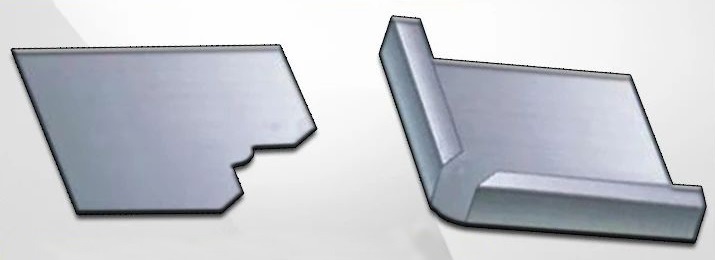

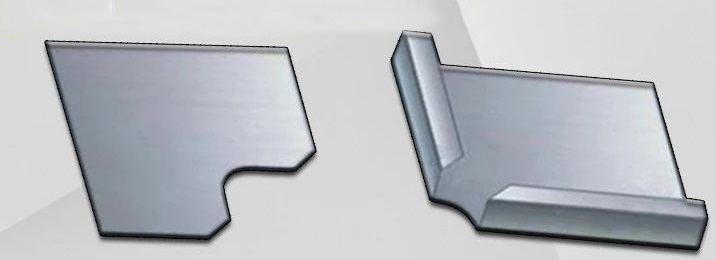

- Versatility: Standard tooling meets most sheet metal processing needs, no need for custom molds like punch presses.

Adjustable Angle Hydraulic Notching Machine – 60°-135°

Applications

- Stainless Steel Sheet Metal Parts: Used in various industries like manufacturing, automotive, and construction.

- Refrigerator Shells: Precision notching for metal parts of refrigerator enclosures.

- Air Conditioner Housing: Metal sheet cutting for air conditioning units and their casings.

- Automotive Body Panels: Cutting and notching of metal components for vehicle body frames and doors.

- HVAC Ductwork Components: Notching of metal for air ventilation ducts and related parts.

- Electrical Enclosures: Metal parts for housing electrical devices, switchgear, and circuit breakers.

- Metal Furniture Components: Cutting for the production of metal parts used in furniture, such as frames or supports.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.