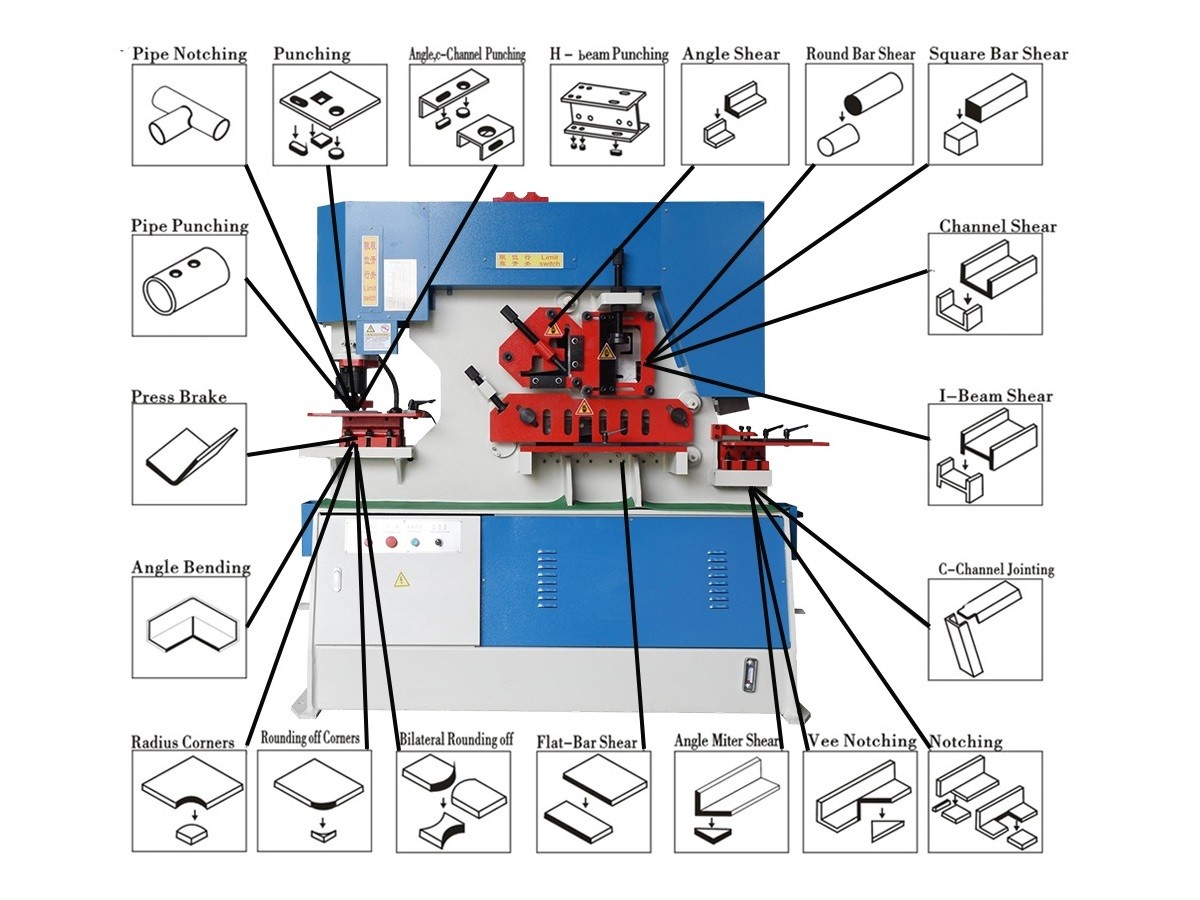

Hydraulic Ironworker Machine for Shearing, Punching, Bending, and Notching

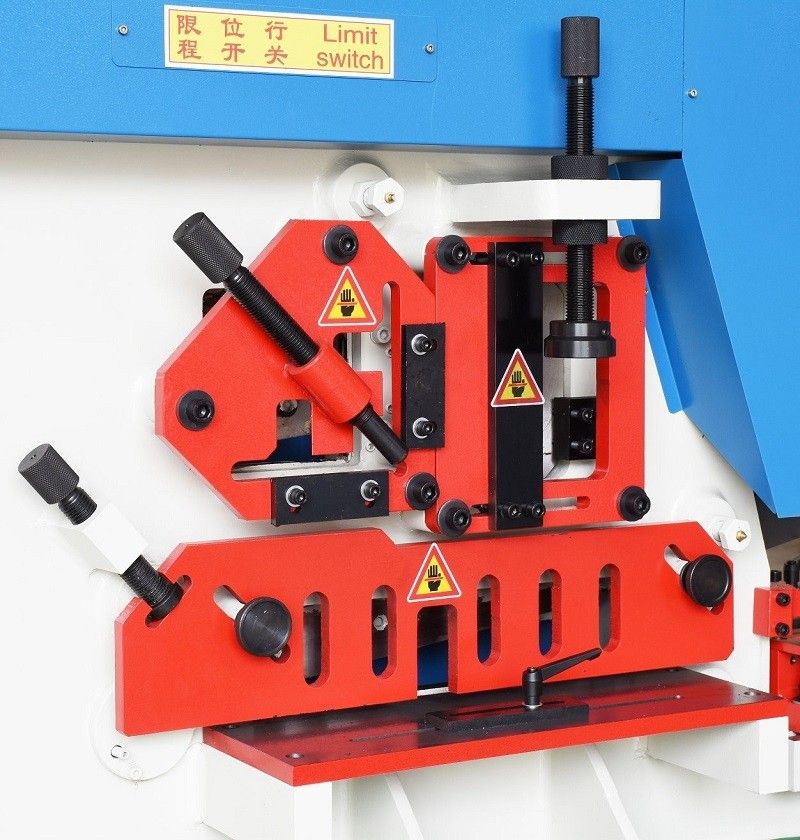

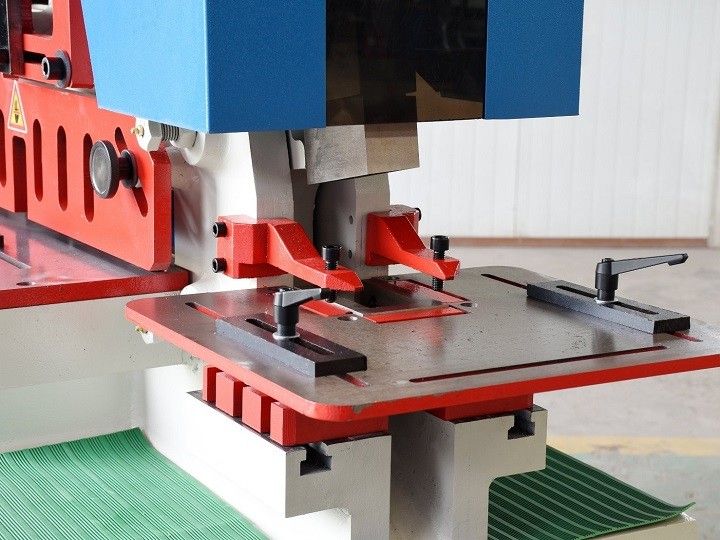

1. Punching Stations:

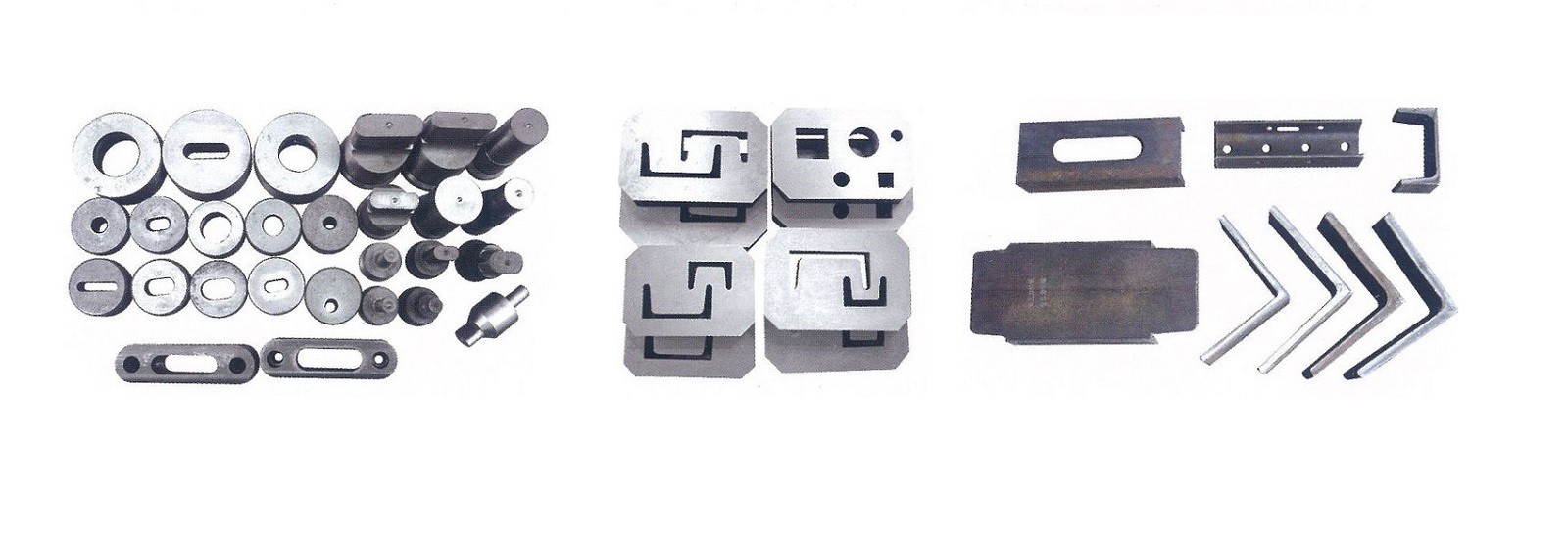

- Full Range of Universal Punches & Dies: Includes a variety of punches for round, square, and oblong holes, as well as louver punching.

- Unique Design for Large Angle Iron & Channel Punching: Capable of punching large angle irons and channels with ease.

- Viewing Window & Stripper Swing-Away Design: Provides a clear view of the punching process and allows easy access for operation.

- Two-Piece Gauging Table: Standard table includes rulers and stops for accurate material positioning.

- Quick-Change Coupling Nut & Sleeve: Enables fast die replacement for increased efficiency during production.

2. Shearing Stations:

- Round & Square Bar Shearing:

- Multiple holes are available for cutting various sizes of round and square bars.

- Adjustable hold-down device for secure cutting of round bars, square bars, channel, and beams.

- Angle Steel Shearing: Cuts at 45° on both top and bottom legs for precise, clean cuts, enabling perfect picture frame corners for welding.

- Diamond-Shaped Blades: Ensures clean cuts, minimizing material loss and deformation.

- Hold-Down Device for Accurate Plate Cutting: Easily adjustable to ensure precise shearing.

- Large 15” Squaring Arm with Inlaid Scale: Enhances accuracy and material positioning.

- Anti-Distorted Blade Design:

- Special blades for quality cutting with four usable edges on the lower blade.

- Screw-based gap adjustment (no shim required) for precise cutting.

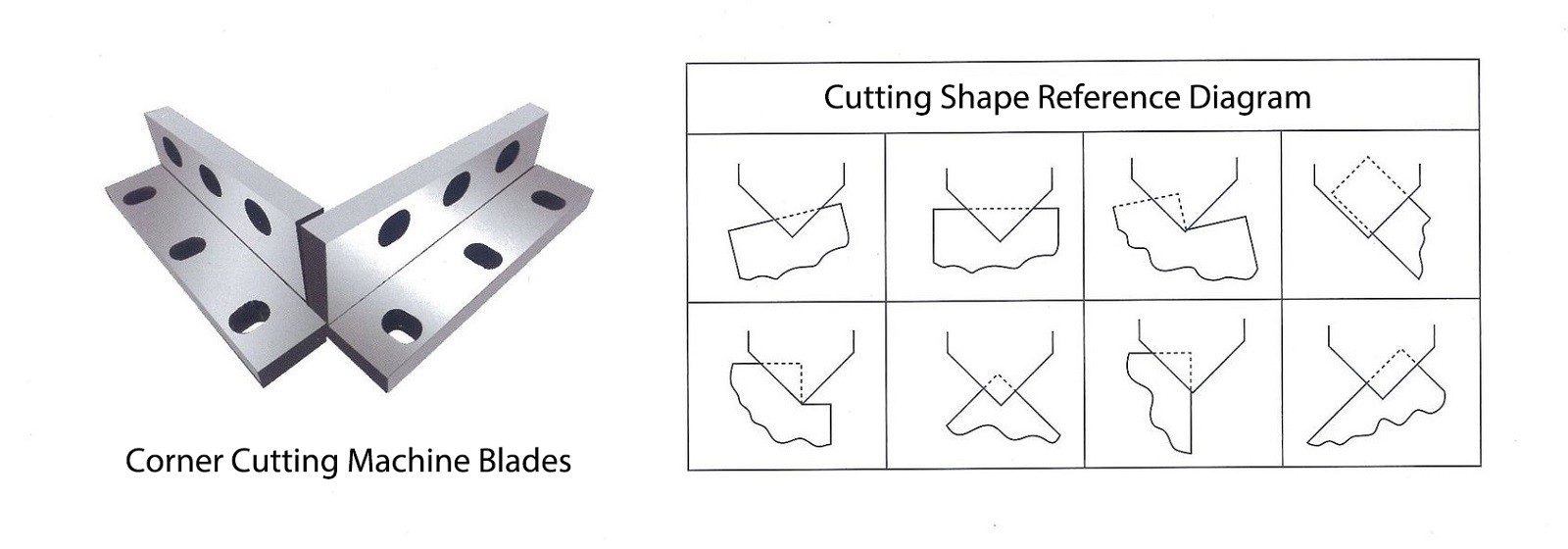

3. Notching Station:

- Versatile Notching: Designed for cutting both angled and flat bars.

- Oversized Notching Table with Material Stops: Provides a large surface for handling and positioning materials.

- Electrical Interlock Safety Guard: Ensures safe operation with three gauging stops for precise material placement.

- Optional Vee Notcher: Available for additional notching capability.

4. Bending Station:

- Bending Capacity: The ability to bend plates up to 500mm in width.

- High-Quality Components: All components are designed for superior performance, ensuring safety and functionality during bending operations.

Machine Function:

- Slot and Square Hole Punching & Dies

- Channel Hole Punching

- Four-Hole Punching

- 1-Beam Hole Punching

- Louver Hole Punching

- Square Tube Punching

- Pipe Joint Punching

- Round-Off Corner Punching

- Angle Notching and Bending

- Channel Joint

- Channel Cutting

- Flat Sheet Cutting

- Angle Steel Cutting

- Channel Steel Cutting

- Square and Round Steel Cutting

Advantages and Features:

Hydraulic System:

- Integrated Hydraulic Control System: Equipped with high-quality PARKER seals (USA), ensuring reliable performance and long service life.

Machine Blades:

- Long-Lasting Rectangular Monoblock Blades (SKD11): Blades feature four cutting edges for extended life and consistent cutting performance.

Electrical System and Safety Interlock:

- European Electrical Components: Reliable and anti-interference electrical components, designed to meet international safety standards.

- Radiation Protection: Electrical cabinet includes radiation protection for safe operation.

- Protective Fence and Safety Interlock: Built-in safety interlocks and a movable single-hand pedal switch for added user protection.

Advantages:

- Removable Table Block: Allows for overhang channel/joist flange punching applications.

- Centralized Pressure Lubrication System: Ensures smooth operation and reduces wear on hydraulic components.

- Large Punch Table with Multi-Purpose Bolster: Features a universal die bolster for easy changeover of punches and dies.

Optional Equipment:

- Laser Positioning: For precise cutting alignment and better accuracy.

- Angle & Round Steel Automatic Positioning: For enhanced shearing accuracy.

- Shear Plate Hydraulic Clamping: Provides secure material handling during shearing operations.

- Louver Punching: For producing ventilation holes.

- Vee Notcher: For additional notching options in thicker materials.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.