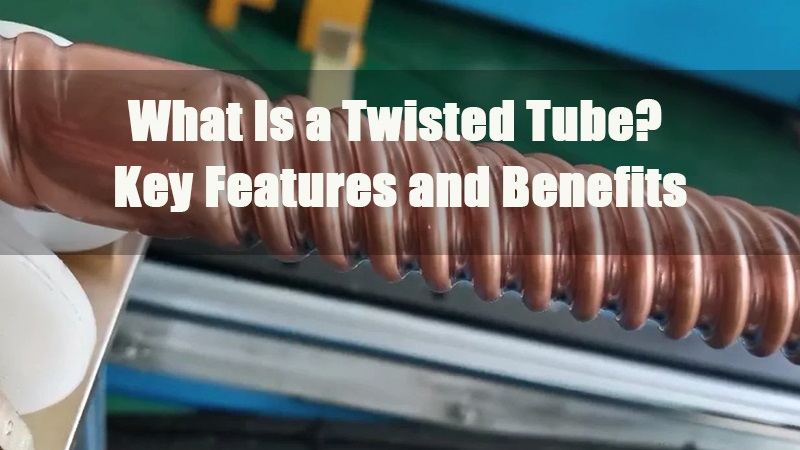

Heavy-Duty Hydraulic Pipe End Shrinking and Forming Machine Features of the Machine:

- Versatile Processes: Capable of shrinking, expanding, flaring, sealing, flanging, rolling, taper forming, and more.

- Operation Modes: Supports manual, semi-automatic, and fully automatic modes, adaptable to various working conditions.

- High Safety: Equipped with a mobile foot pedal switch for emergency stops.

- Cooling System: Ensures stable and reliable machine operation.

- Precision Control: Utilizes a closed-loop hydraulic circuit for accurate machine control.

- Mold Replaceability: Interchangeable molds provide versatility for different product requirements.

- Stable and Precise Work: Linear guide rails ensure stable, accurate operation and high product quality.

- NC Control with Touch Screen: The server drive has user-friendly controls that ensure ease of operation and precision.

- Stepper-Forming (Optional): Guarantees size and quality stability during production.

Hydraulic Heavy-Duty Tube End Forming and Reducing Machine Testing Site:

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.