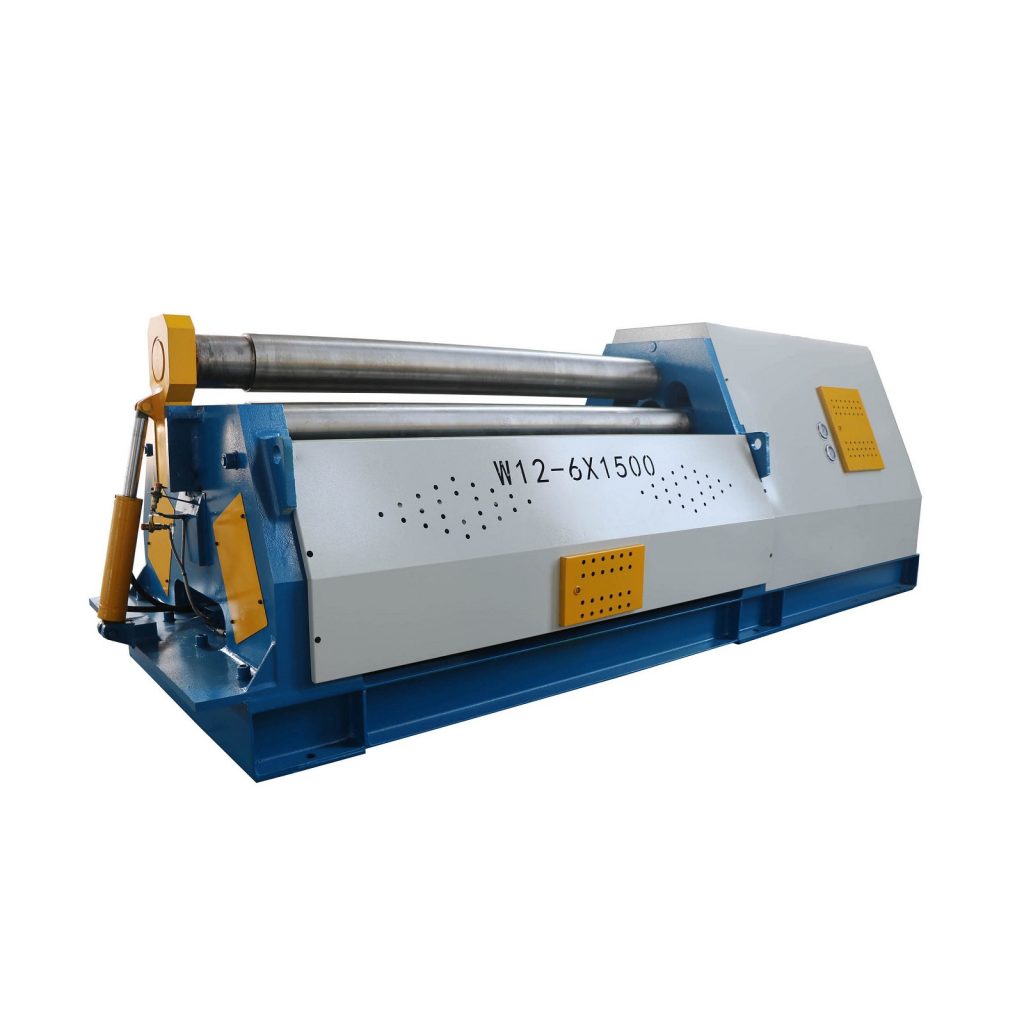

Machine Photos and OEM Customization

Machine Structure and Features:

-

Upper Roller and Lowering Device: The upper roller is made of 45# steel forging, medium-frequency quenched, with a hardness of HB300- 350. The lowering device is driven by a secondary motor, oil pump, solenoid valve, and hydraulic cylinder for vertical movement.

-

Lower Roller: The active lower roller is made of 45# steel forging, medium-frequency quenched, with a hardness of HB300- 350. The main motor, a cycloidal needle gearbox, and a coupling drive it.

- Main Drive System: This includes the main motor, cycloidal needle gearbox, and brake system.

- Structural Design: The machine features steel plate-welded side frames and base, with post-weld vibration aging to enhance strength and stability.

- Hydraulic System: The hydraulic system consists of a gear pump, valve group, and auxiliary piping, all designed for high pressure and speed. Stack valves are arranged for a simple layout and minimal leakage.

- Electrical Control System: The electrical control cabinet and operation panel are powered by 380V/50Hz. This system includes short-circuit and overload protection.

Working Principle:

The upper roller is positioned centrally between the two lower rollers. The hydraulic cylinder controls the vertical movement of the upper roller, applying pressure to the metal plate. This pressure causes the plate to undergo plastic deformation due to the combined action of the downward pressure from the upper roller and the rotation of the lower rollers.

The plate bending machine completes the continuous bending of the steel plate using the three rollers (two lower rollers and one upper roller), ultimately forming the required conical structure.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.