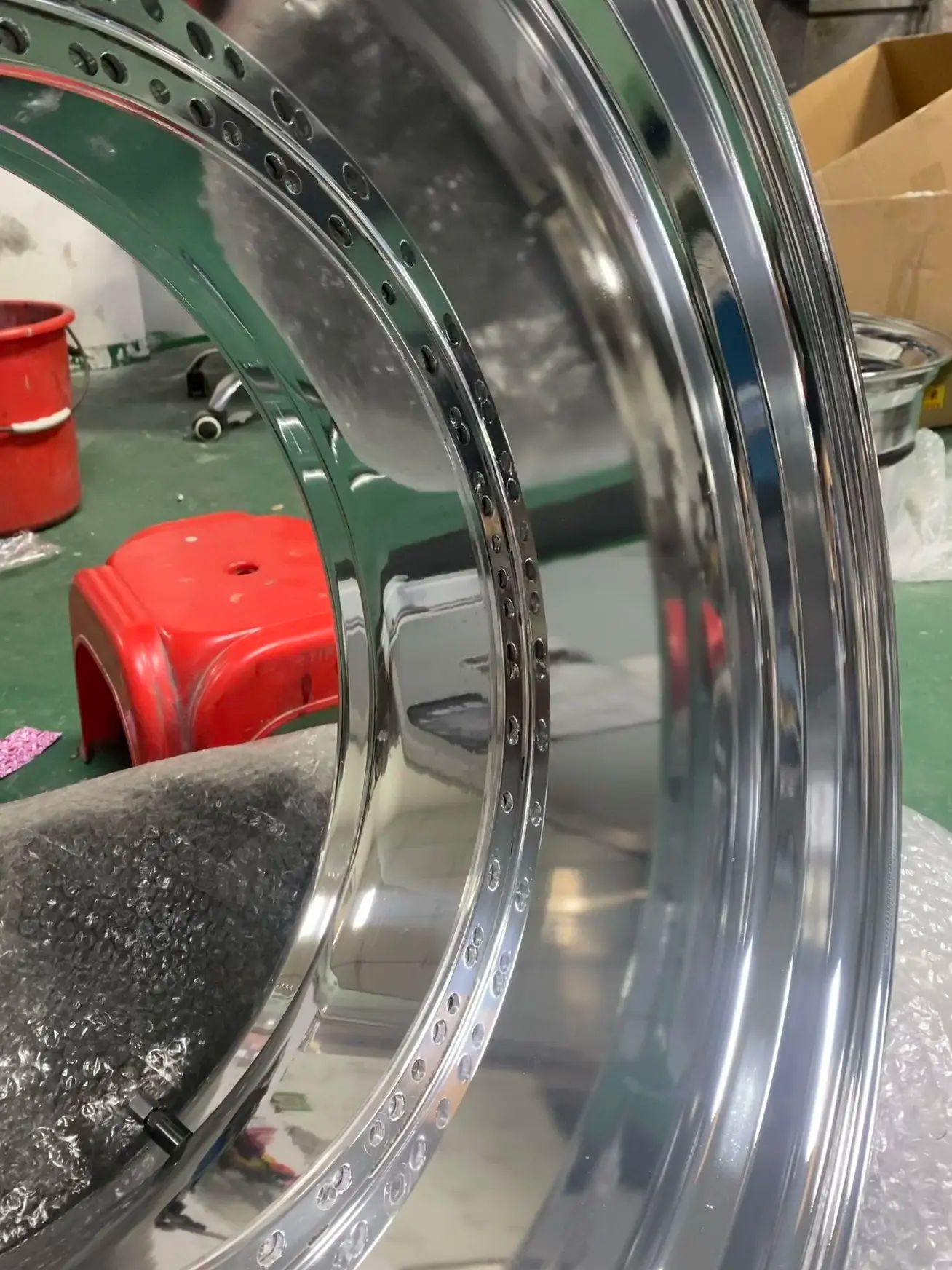

Alloy aluminum wheels can accumulate oxidation, scratches, and road grime over time, dulling their appearance. Following the correct sanding and polishing techniques, you can remove imperfections and restore your wheels to a shiny, mirror-like finish. This detailed guide walks you through each step to master the polishing process.

1.0 Preparation

1.1 Gather Tools and Materials

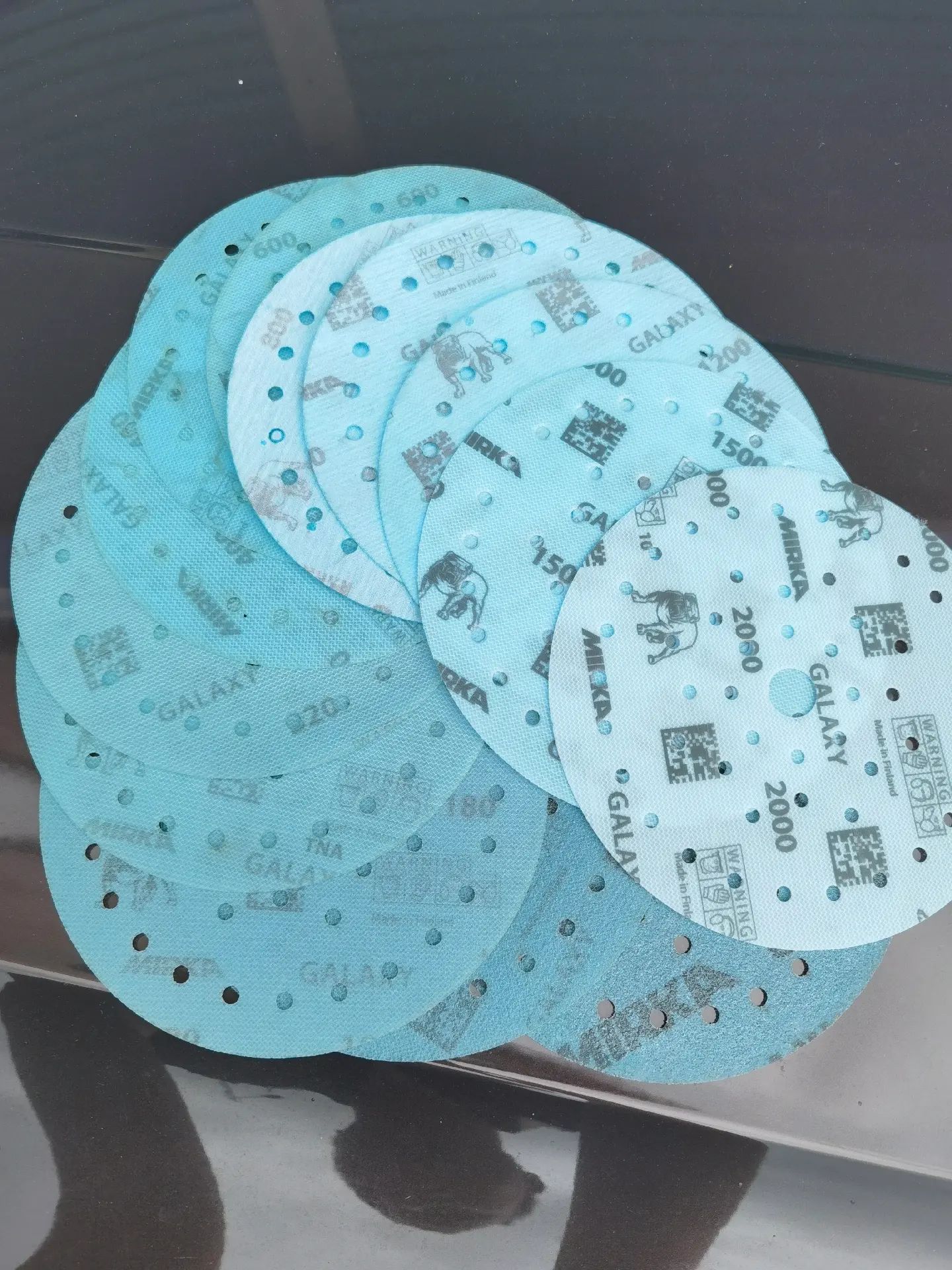

- Sandpaper: Use sandpaper of various grits. Start with a low grit (e.g., 80) to remove deep scratches and progress to higher grits (up to 2000) for fine sanding. Recommended grit sequence: 80, 150, 320, 600, 1200, 2000.

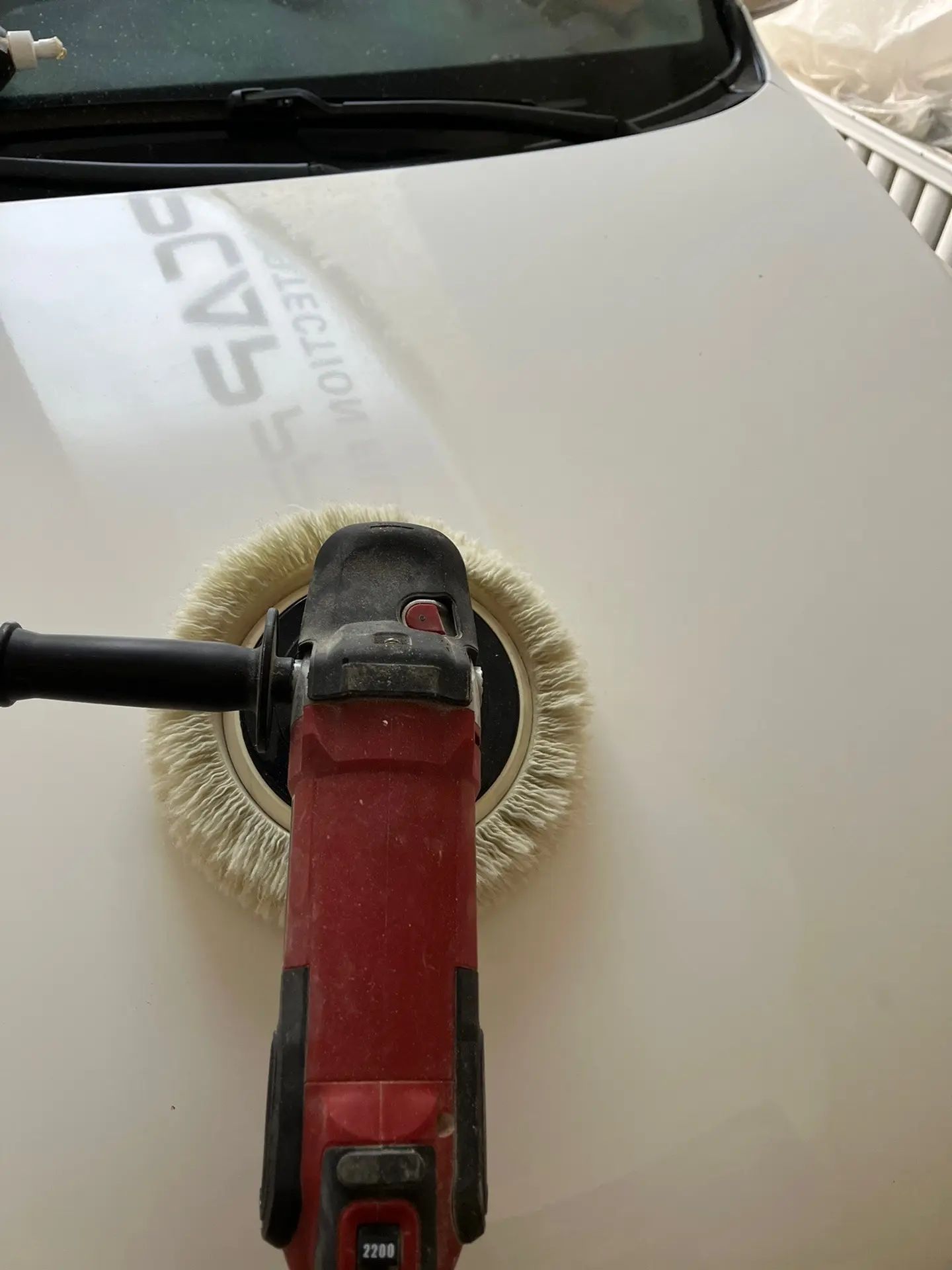

- Polishing Machine: An electric or pneumatic polishing machine is essential for efficient polishing. Choose one suitable for your wheels’ size and material.

- Wool Pads and Polishing Discs: Use these to apply polishing compounds evenly for a mirror-like effect.

- Polishing Compound: Use a specialized aluminum alloy compound, starting with coarse polish and finishing with fine polish for added shine.

- Safety Gear: Wear anti-slip gloves and safety goggles to ensure safe operation.

1.2 Remove and Clean the Wheels

- Detach the Wheels: Remove the wheels from the vehicle and place them on a stable workbench.

- Clean Thoroughly: Wash the wheels with a cleaner or a mix of warm water and dish soap. A brush can help remove grime, brake dust, and old wax. For stubborn stains like tar, use a tar remover. Rinse thoroughly and dry completely.

Inspect the Condition

- Scratches and Dents: Minor scratches can be polished, but deeper ones require filling and repair before proceeding.

- Oxidation: Light oxidation can be polished away, while severe oxidation may require chemical treatment or repainting.

2.0 Sanding and Polishing Process

2.1 Coarse Sanding (Initial Sanding)

- Choose Abrasive: Start with 80-400 grit dry sandpaper to remove deep scratches and level uneven surfaces. Technique: Wrap the sandpaper around a sanding block or pad to maintain even pressure. Follow the wheel’s shape and grain for consistent results. Take extra care with edges and spokes to avoid over-sanding.

2.2 Medium Sanding (Refinement)

- Switch Abrasiv es: After coarse sanding, use 400-800 grit wet sandpaper. Wet sanding reduces clogging and improves efficiency.

- Gradual Progression: Use a sequence of 400 to 800 grit, skipping intermediate grits if necessary. Inspect for pores or dents during this step and fill as needed before continuing.

2.3 Fine Polishing

- Set Up the Polisher: When using a polishing machine, set the speed to 1500-2500 RPM for smooth results. Apply the polishing compound according to the manufacturer’s instructions.

- Apply Evenly: Use a yellow wool pad to spread the compound, gradually increasing speed to a maximum of 3000 RPM. Ensure even contact with the surface to prevent patchy shine.

Hand Polishing (Optional):

If polishing by hand, use a polishing cloth and liquid polish. Spread the polish evenly and rub gently. Avoid excessive force to prevent scratching.

3.0 Mirror Finish and Protection

3.1 Achieve a Mirror-Like Shine

- Final Sanding: Use ultra-fine sandpaper (1200-2000 grit) for the finishing touch, ensuring a smooth and glossy surface.

- Polishing Tips: Control the machine’s speed and pressure carefully to avoid over-polishing, which can damage coatings or create uneven gloss.

3.2 Protective Coating

- Apply Protectant: Use a metal protectant or clear coat to shield the aluminum from oxidation. Apply a thin, even layer and let it dry thoroughly.

4.0 Final Steps

4.1 Detailing

- Polish Edges and Spokes: Use small tools to access tight spaces, avoiding over-polishing.

- Inspect and Install: Check the wheels for cleanliness and integrity before reinstallation. Use a torque wrench to secure the wheels in a crisscross pattern.

5.0 Maintenance and Troubleshooting

5.1 Common Issues

- Persistent Scratches: Re-sand with a lower grit or use a filler for deep scratches before resuming the process.

- Compound Residue: Wipe with a soft, damp cloth to remove residue.

- Uneven Shin e: Ensure consistent pressure and grit progression during sanding and polishing.

- Oxidation: For severe cases, use an aluminum oxidation remover or perform chemical cleaning.

5.2 Ongoing Care

- Regularly clean the wheels with mild soap and a soft cloth.

- Avoid harsh chemicals to preserve the protective coating.

6.0 Conclusion

By following these steps, you can restore your alloy aluminum wheels’ original shine, enhancing your vehicle’s overall appearance. Proper polishing and maintenance ensure that your wheels remain both visually appealing and durable for the long term.