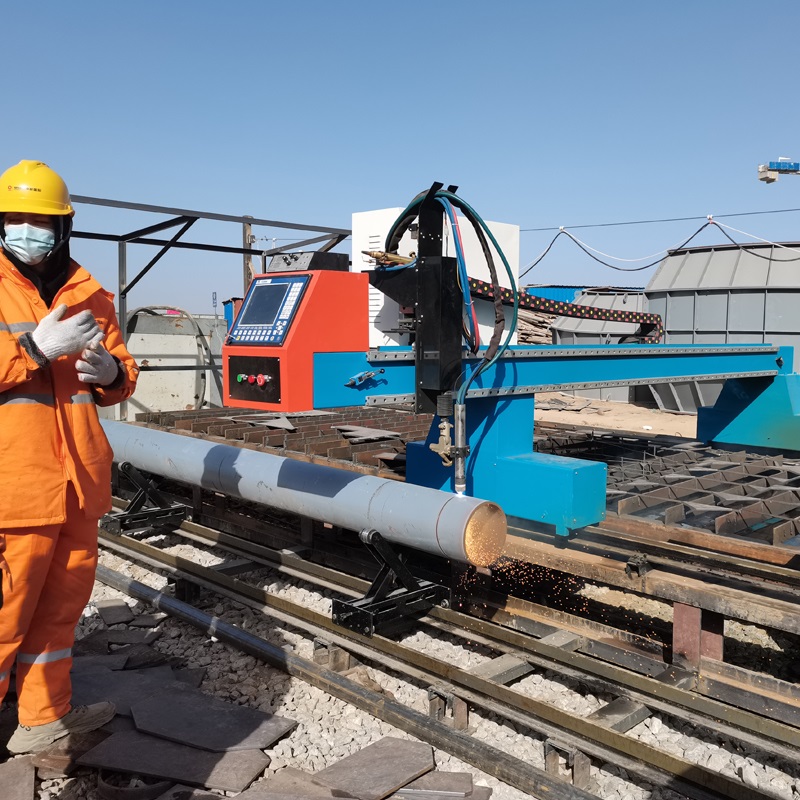

CNC Gantry Plasma & Flame Cutter for Industrial Metal Cutting

- Various metal materials such as steel, copper, aluminum, stainless steel, etc.

- Iron plate, aluminum plate, galvanized sheet, white steel plate, titanium plates, etc.

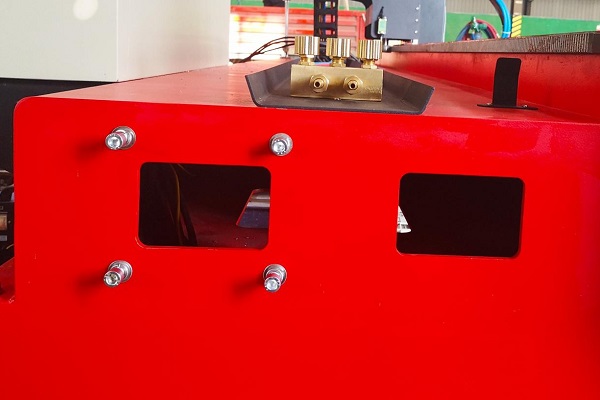

Industrial Gantry CNC Plasma Cutting Machine for Precision Metal Cutting Main Features

- Lightweight Structural Design: The beam features a lightweight design that offers good rigidity, low inertia, and cost-effectiveness.

- Gantry Structure: The Y-axis utilizes a synchronous dual-motor drive, while the XYZ axes are equipped with circular rails (optional linear guides), ensuring steady transmission and high accuracy.

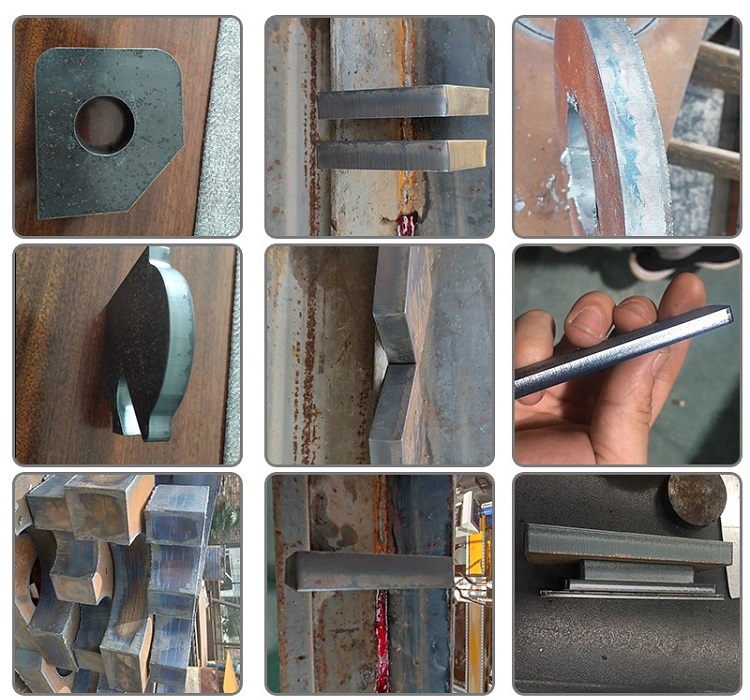

- Cutting Precision: Ideal for cutting solid light for advertising, groove metal panels, and bottom plates of letters, with excellent cutting accuracy. When paired with U.S. Hypertherm plasma power, it delivers cutting results comparable to laser machines.

- Advertising Letter Automation: This can be integrated with vacuum-forming machines and gear-cutting machines to create an automated processing line for advertising letters, significantly improving efficiency.

- CNC System: Features a high-performance CNC system with automatic arc detection, ensuring a 99% success rate in arc ignition.

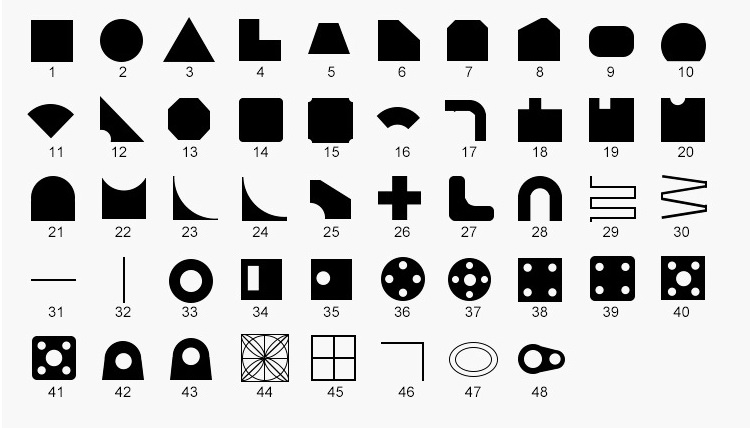

- Software Compatibility: Supports software such as Wentai, Beihang Haier, ARTCAM, and Type3, and can read standard G-code paths and DXF files generated by AUTOCAD. Files can be easily exchanged via USB for user-friendly operation.

Custom appearance for customers

Product Specifications

- Frame Structure: The frame is made from carbon steel welded structure and treated with overall annealing, ensuring high precision and low inertia. The XYZ axes are processed to prevent deformation.

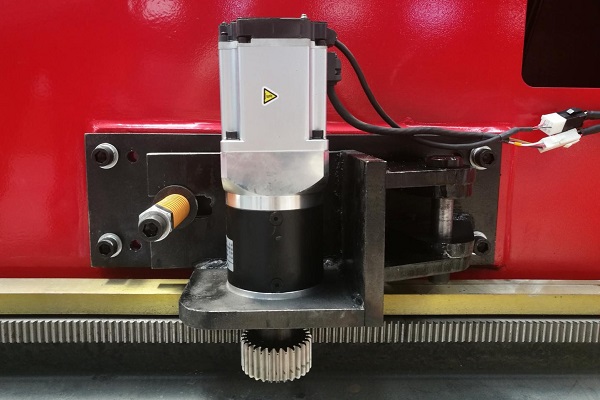

- Transmission System: Features high-precision racks and a special reducer, with cables made from German materials to ensure running accuracy.

- Drive System: Uses U.S. chip control, dual-drive system, and Panasonic servo motors. Optional Inovance servo motors or precision stepper motors provide AC power with high torque, ensuring smooth operation at high speeds.

- High-Precision Controller: The control system has both English and Chinese interfaces, and the machine is equipped with Automatic THC (Torch Height Control).

Other Key Components

- Crossbeam Structure and Machining Process: The crossbeam is welded from formed steel plates, with the top and back bent at a 90-degree angle for increased rigidity and reduced deformation. The front is welded with a 22mm steel plate, and the surface is processed by a gantry planer. After welding, the machine undergoes stress relief, rust removal, primer application, and surface painting.

- Longitudinal Frame: The longitudinal drive consists of 4 rollers, 2 bilateral gears, 2 servo motors, and 2 high-precision gearboxes. Guide scraping devices at the ends of the carriages keep the guide surfaces clean and protect the moving parts from steel slag.

- Dedicated Electrical Control System: The system includes CNC, electrical, and servo subsystems with components from well-known brands. It has a modular structure for easy maintenance and features fault history, alarms, and self-diagnosis for safety.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.