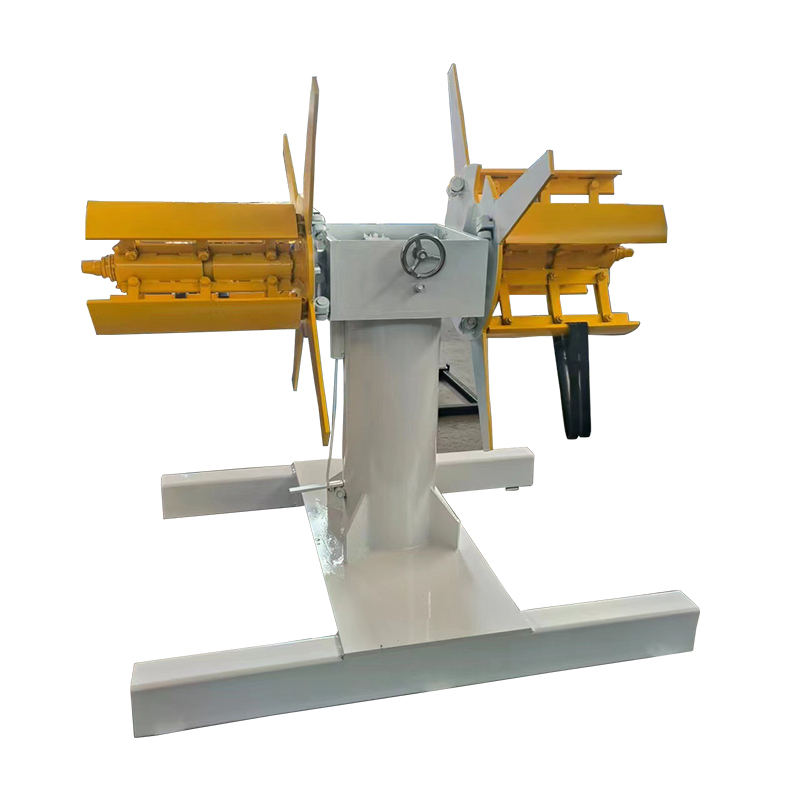

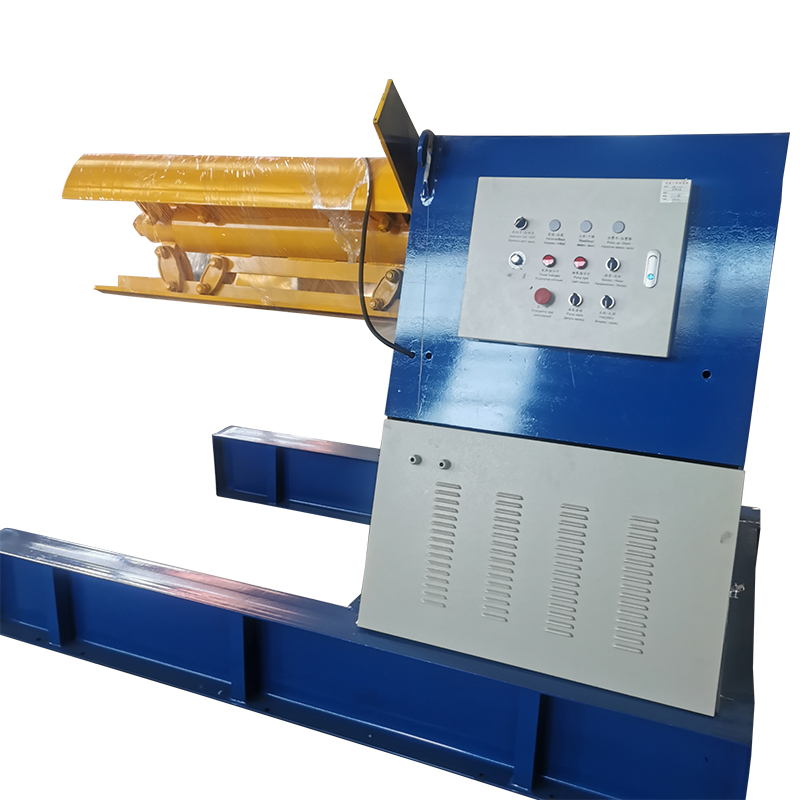

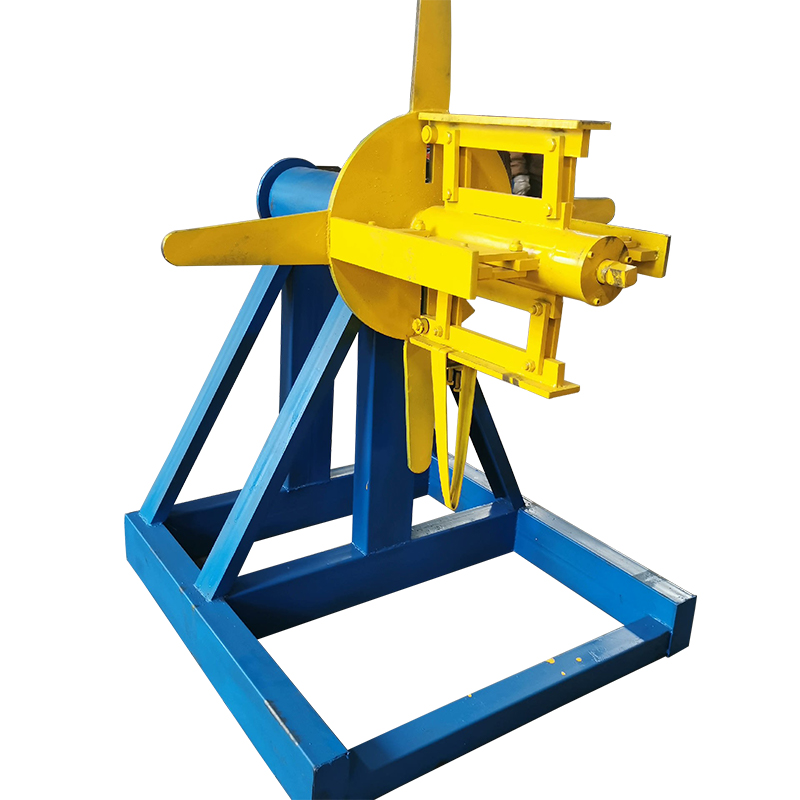

Steel coil decoiling machine is used in metal processing lines

The decoiler is widely employed in automated metal processing production lines, performing the functions of automatic loading, uncoiling, leveling, cold bending, shearing, and punching of metal coils.

The ALEKVS uncoiler is commonly used in metalworking and machinery manufacturing industries, providing flat metal sheet materials as raw inputs for a diverse range of equipment.

It can be seamlessly integrated with punch presses, laser cutting machines, purlin roll forming machine, sheet laminating machine,and other complementary devices to achieve the automated production of metal coils.