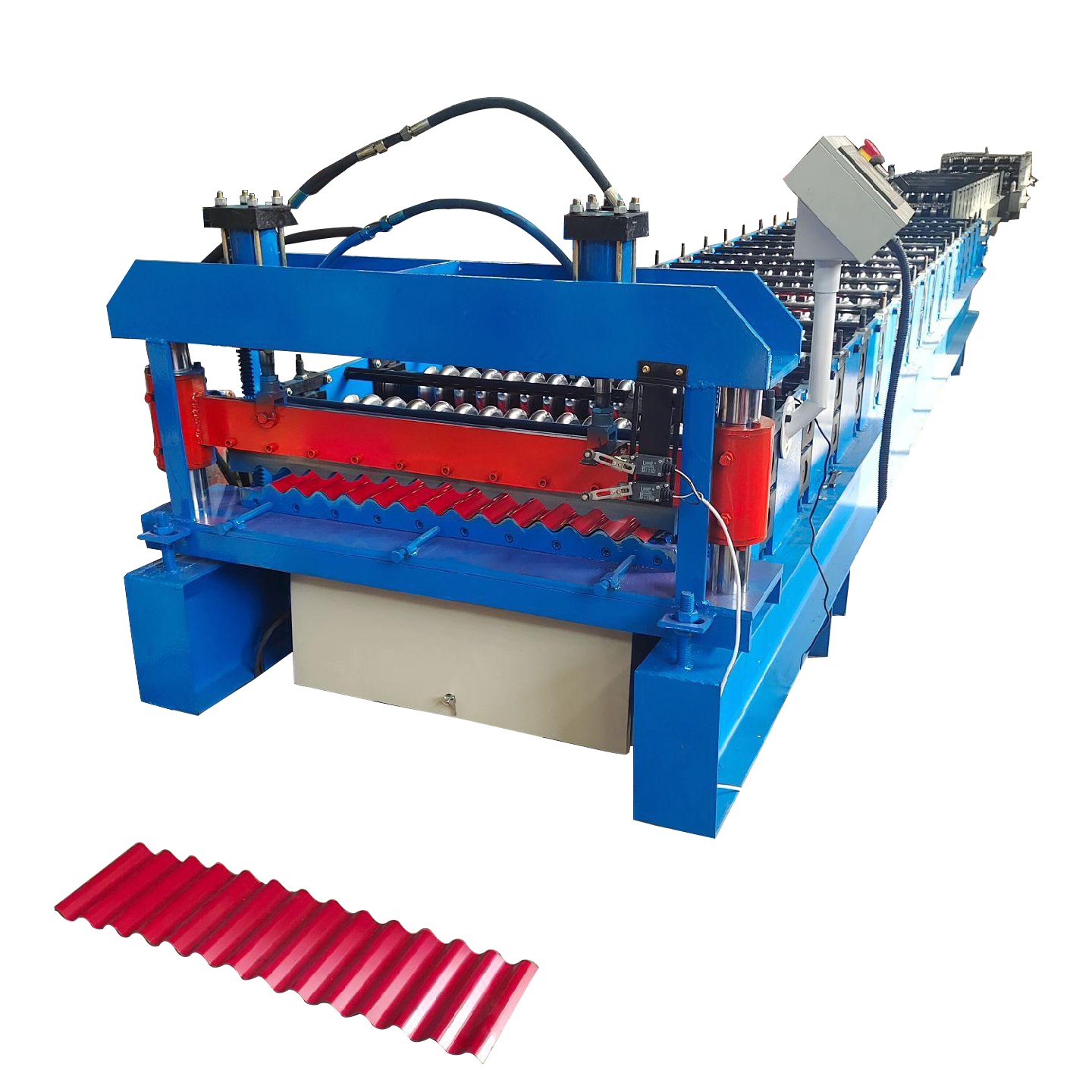

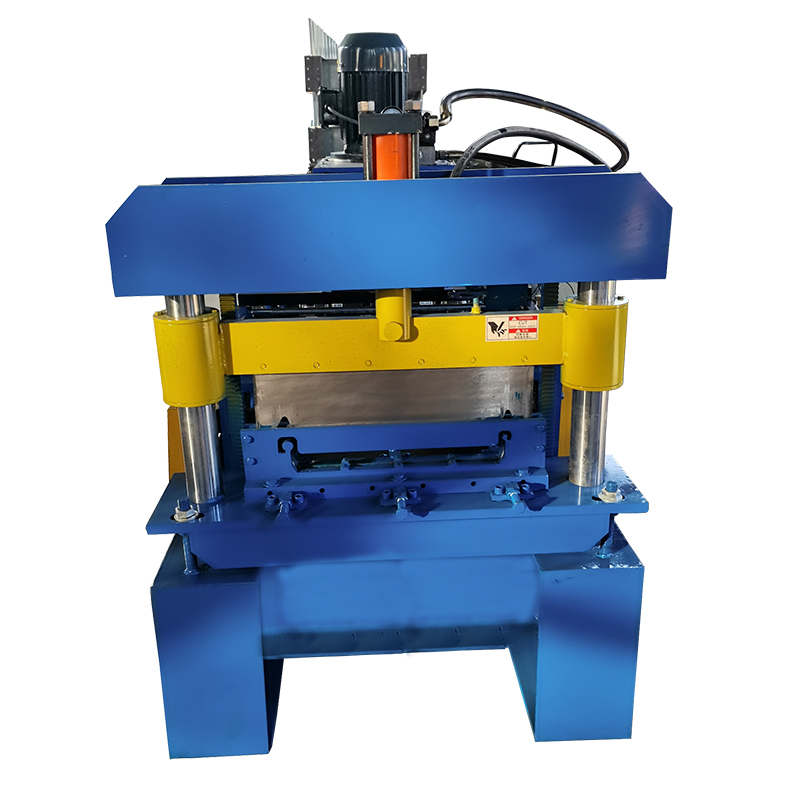

The corrugated iron sheet-making machine is widely used for producing corrugated roofing and siding sheets, especially popular in African markets.

corrugated iron sheet-making machine application:

- Roofs, wall panels, fences, partitions, carports, etc.

- Grain silos, livestock sheds, and greenhouse coverings.

- Pipeline protection and tank shells.

- Bridge and tunnel liners, guardrails, and truck bodies.

ALEKVS corrugated sheet rolling machine offers high efficiency and precision for large-scale production.

corrugated roof roll forming machine composition

- Manual Decoiler: Optional upgrade with a 5-ton hydraulic decoiler for added capacity.

- Entry Feeding Guide: Adjustable to accommodate materials of varying widths for flexibility.

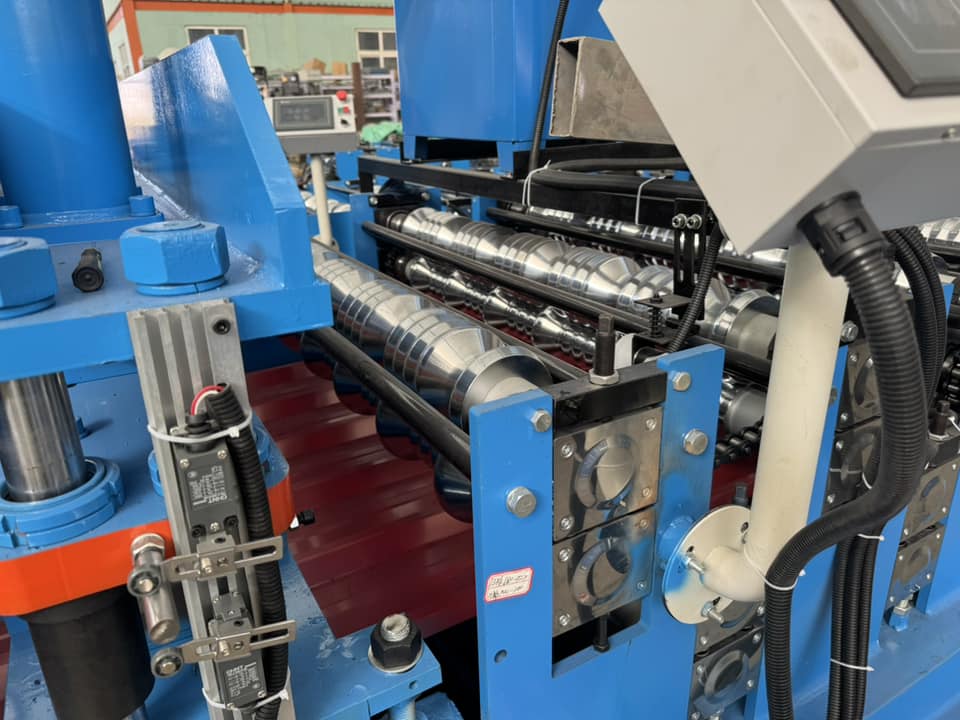

- Roll Forming System: Shapes the material to create the desired corrugated profile for roofing and siding.

- Transmission System: Powers the process and transmits energy to form the sheet.

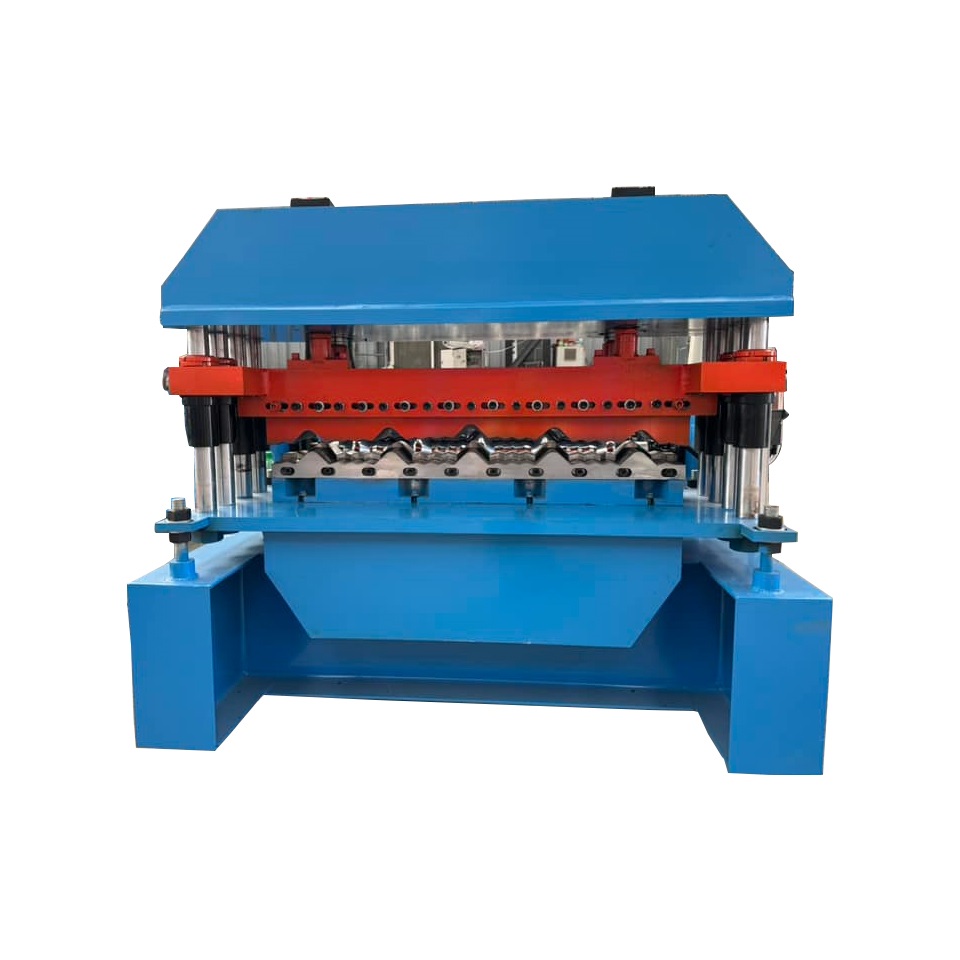

- Hydraulic System: Operates the hydraulic cutter for precision cutting.

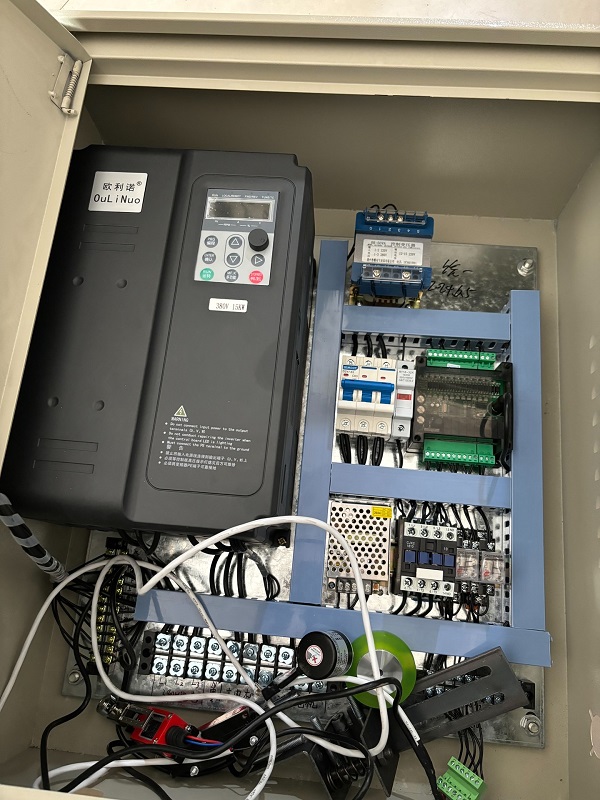

- Control System: PLC control ensures precision and automation for reliable performance.

- Hydraulic Cutter: Equipped with an oil pump for accurate and clean cutting of the final product.

- Runout Tables: Facilitates the collection of finished sheets for further processing.

- Safety Cover: Provides operator protection and complies with CE standards for European markets.

Machine Details

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.