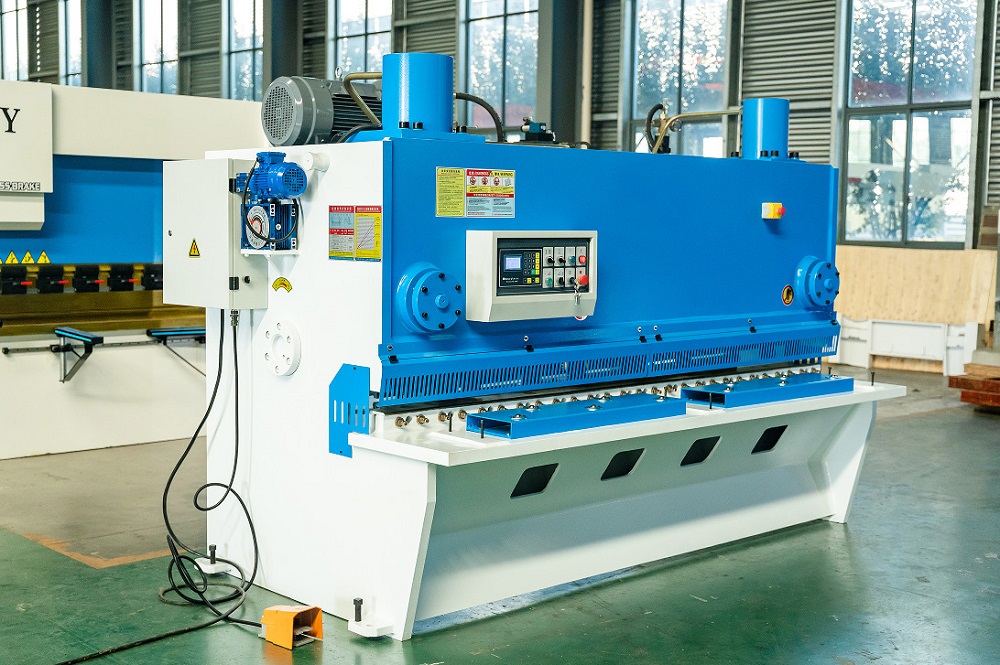

Metal Hydraulic Shearing Machine

- The metal sheet is moved by rolling balls and support blocks on the table. The guillotine shear includes front support arms and a side squaring arm.

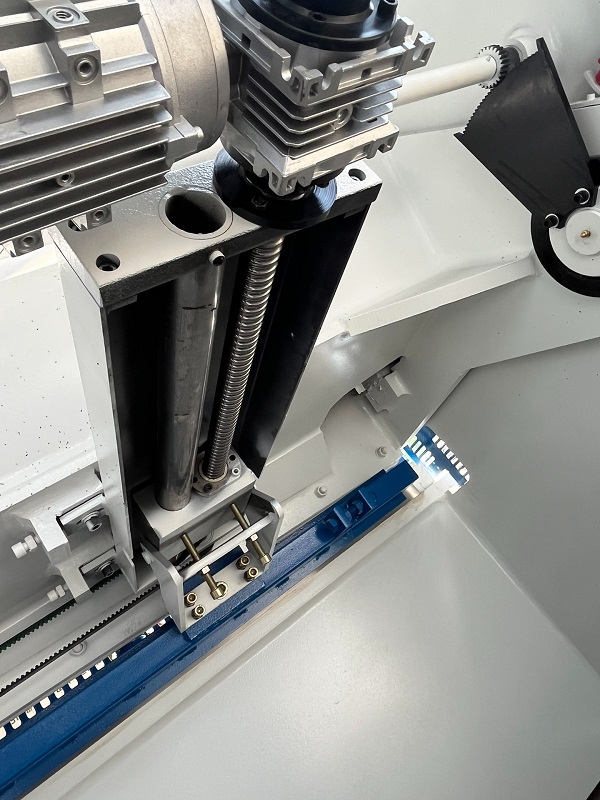

- Closed-loop control system with an NC controller and encoder, featuring automatic inspection and compensation. The back gauge is driven by a DC servo motor, with an X-axis repeat positioning accuracy of 0.1mm.

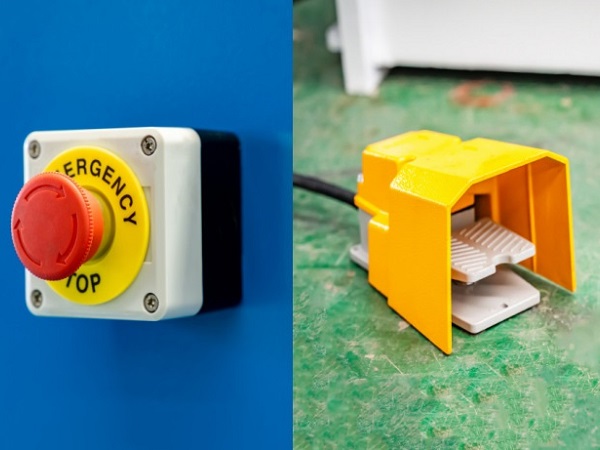

- Protective fence and safety interlocker included. The power supply switch automatically turns off when the electric box door opens or the fence is raised. Includes travel limit protection and an emergency stop switch on the foot pedestal.

- The back gauge is controlled by the E20, DTC660, or DAC-310 control system with a touchscreen.

Hydraulic Metal Shearing Machine Key Features:

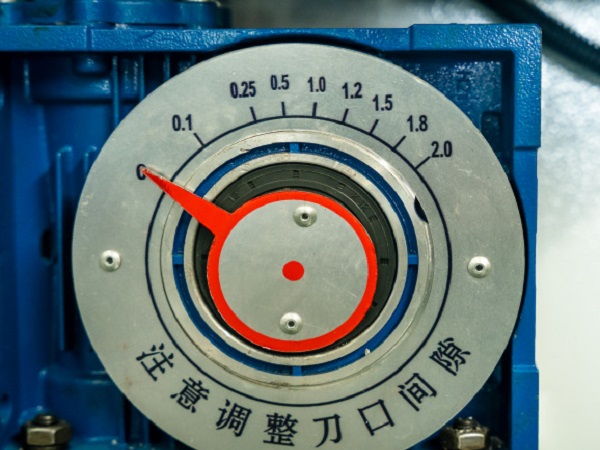

- Electric quick and accurate blade clearance adjustment.

- Multi-edge blades for cutting aluminum, mild steel, and stainless steel.

- Cutting line illumination and shadow line cutting wire.

- Stroke counter and cutting length adjustment.

- Hydraulic and electrical overload protection.

- Squaring arm and front support arms for added stability.

- P40 NC control system with touch screen for easy operation.

- Bosch-Rexroth hydraulic system (Germany).

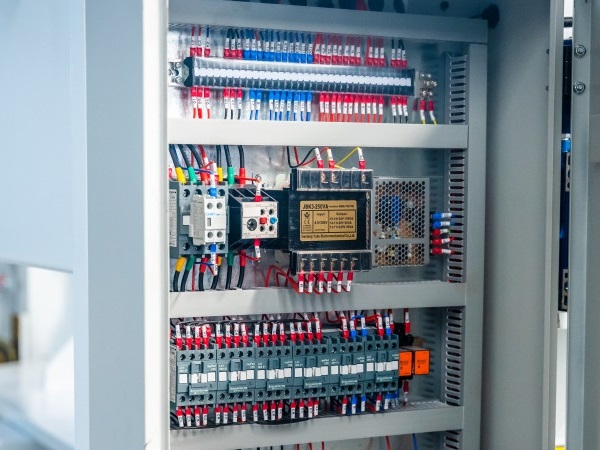

- Schneider electric components.

- Delta inverter with ball screw and polished rod for 0.05mm accuracy.

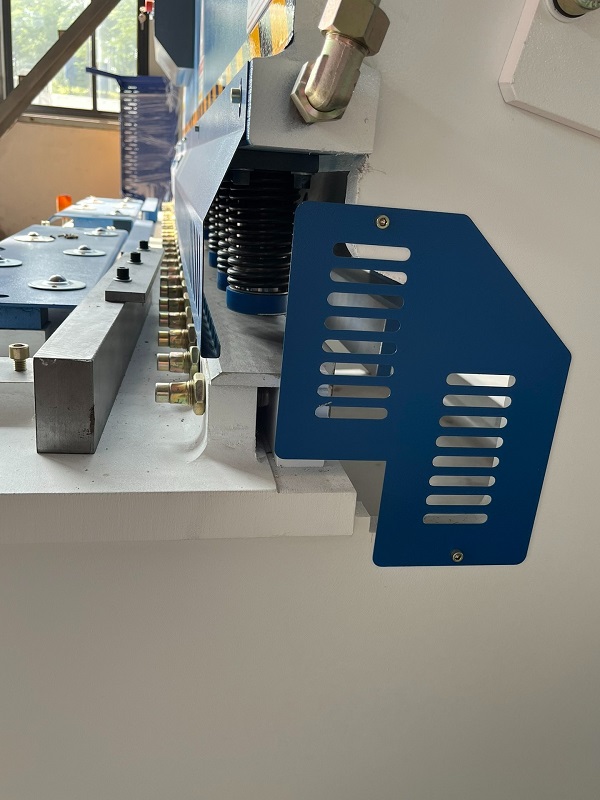

- Side guard meeting CE regulations for safety.

- High Accuracy E21S PLC Controller Sheet Metal Plate Mechanical Shear Machine

Product Description:

- The metal sheet is moved easily by rolling balls and support blocks to maintain surface quality. Includes front support arms and a side squaring arm.

- Closed-loop control system with an NC controller and encoder for automatic inspection and compensation. The back gauge is driven by a DC servo motor with 0.1mm X-axis repeat positioning accuracy.

- Protective fence and safety interlock. The power supply automatically turns off when the box door opens or the fence is raised. Includes travel limit protection and an emergency stop switch.

- The back gauge is controlled by E20, DTC660, or DAC-310 touchscreen control systems.

- Automatic blade gap adjustment via the control system.

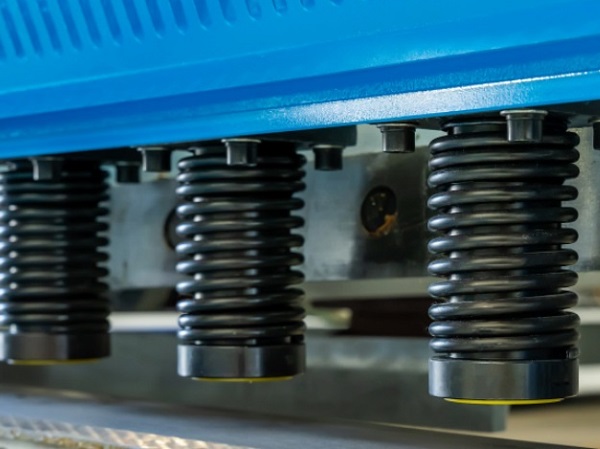

- Structure: The machine features a fully welded box bed frame for high stiffness and vertical linear movement, minimizing distortion and ensuring straightness.

- Control System: Equipped with a Delem DAC360 CNC system (or optional E21S controller) to manage the backstop, blade angle, and blade gap adjustments.

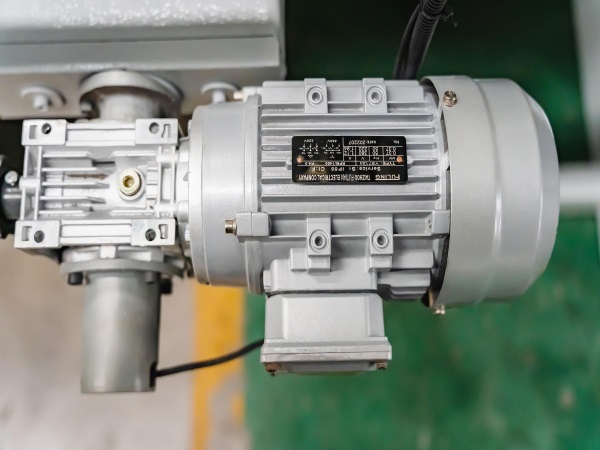

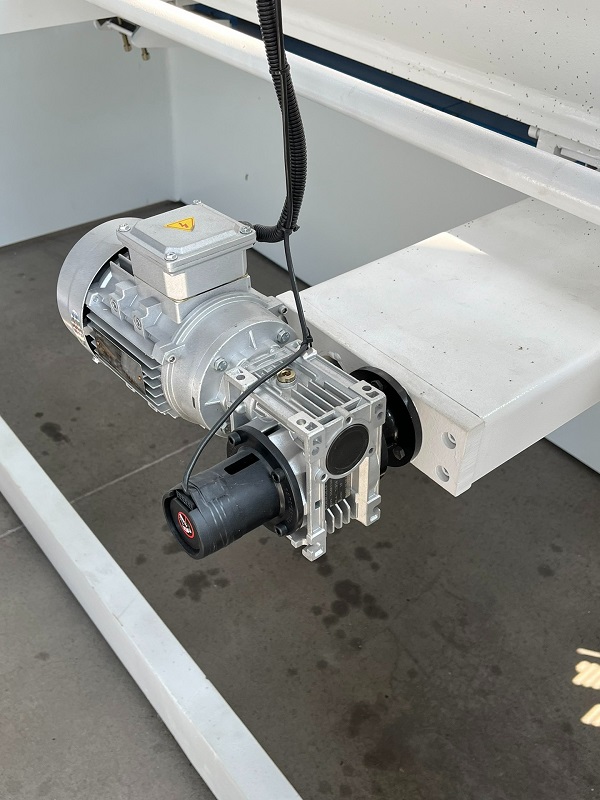

- Motor: Powered by a Siemens or Wannan motor, with customizable voltage options (e.g., 3-phase/220V/60Hz, 3-phase/380V/60Hz).

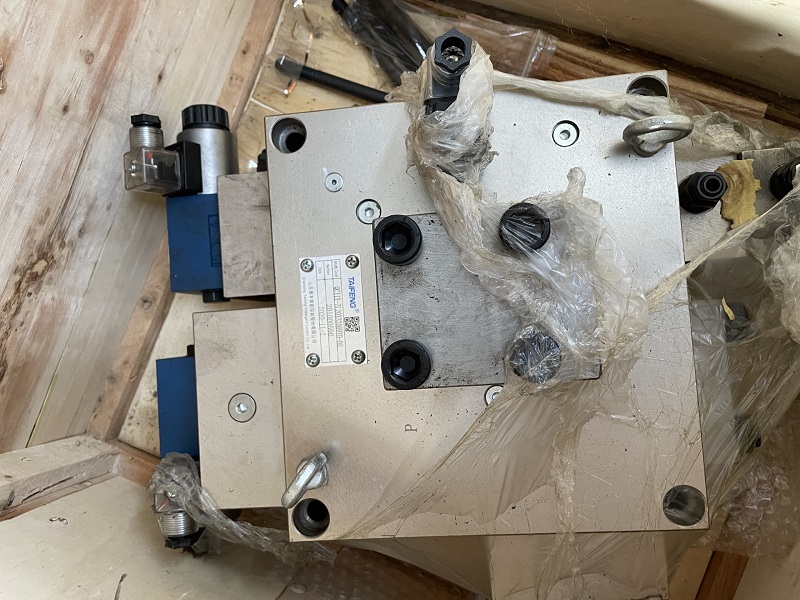

- Hydraulic Valve: Uses a Rexroth hydraulic valve block for overload protection and stable operation, with real-time oil pressure monitoring.

- Feeding Port: Complies with safety standards, featuring adjustable height screws and front fence and side guardrails for safety.

- Cutting Line Illumination: Equipped with a light alignment device for easy marking, with a steplessly adjustable blade holder stroke for precision

CNC Hydraulic Guillotine Shearing Machine for Metal Sheet Cutting-OEM

ALEKVS hydraulic sheet shearing machine Includes:

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.