Manufacturing Process Highlights

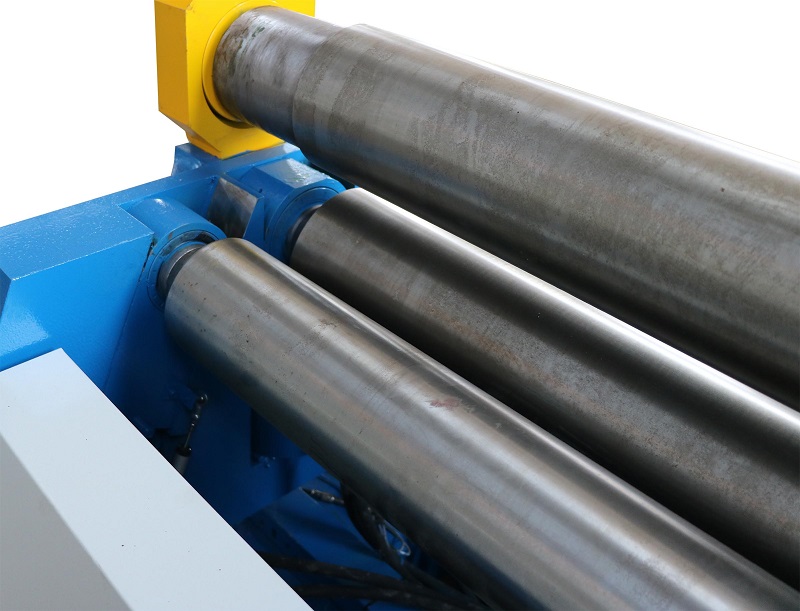

Rollers:

Forged from cast steel ingots → Heat treated (hardening & tempering) → UT flaw detection → Final machining

Large Forgings:

Cylinders, gears, and shafts undergo ultrasonic flaw detection, annealing, and precision machining

Welded Structures:

Racks, chassis, and boxes are welded with strict inspections (chemical, mechanical, RT/UT flaw tests), annealed, and finished with vibration stress relief

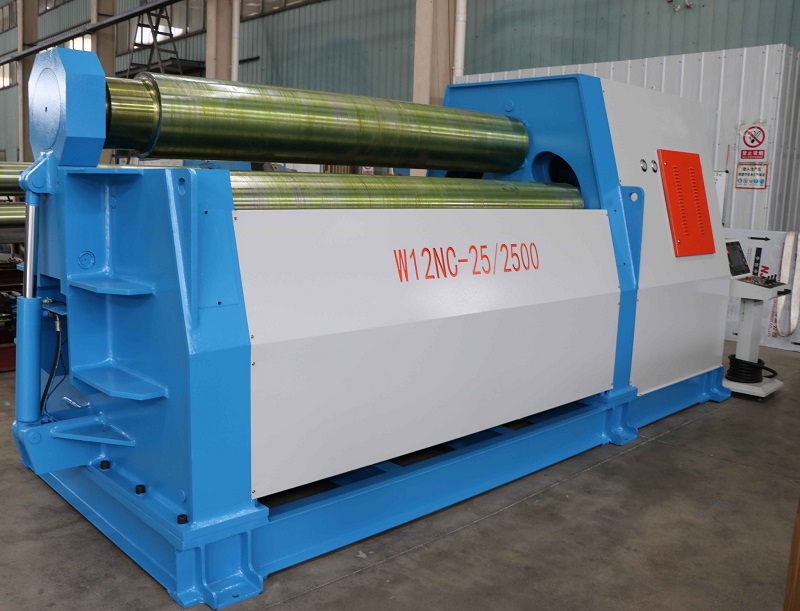

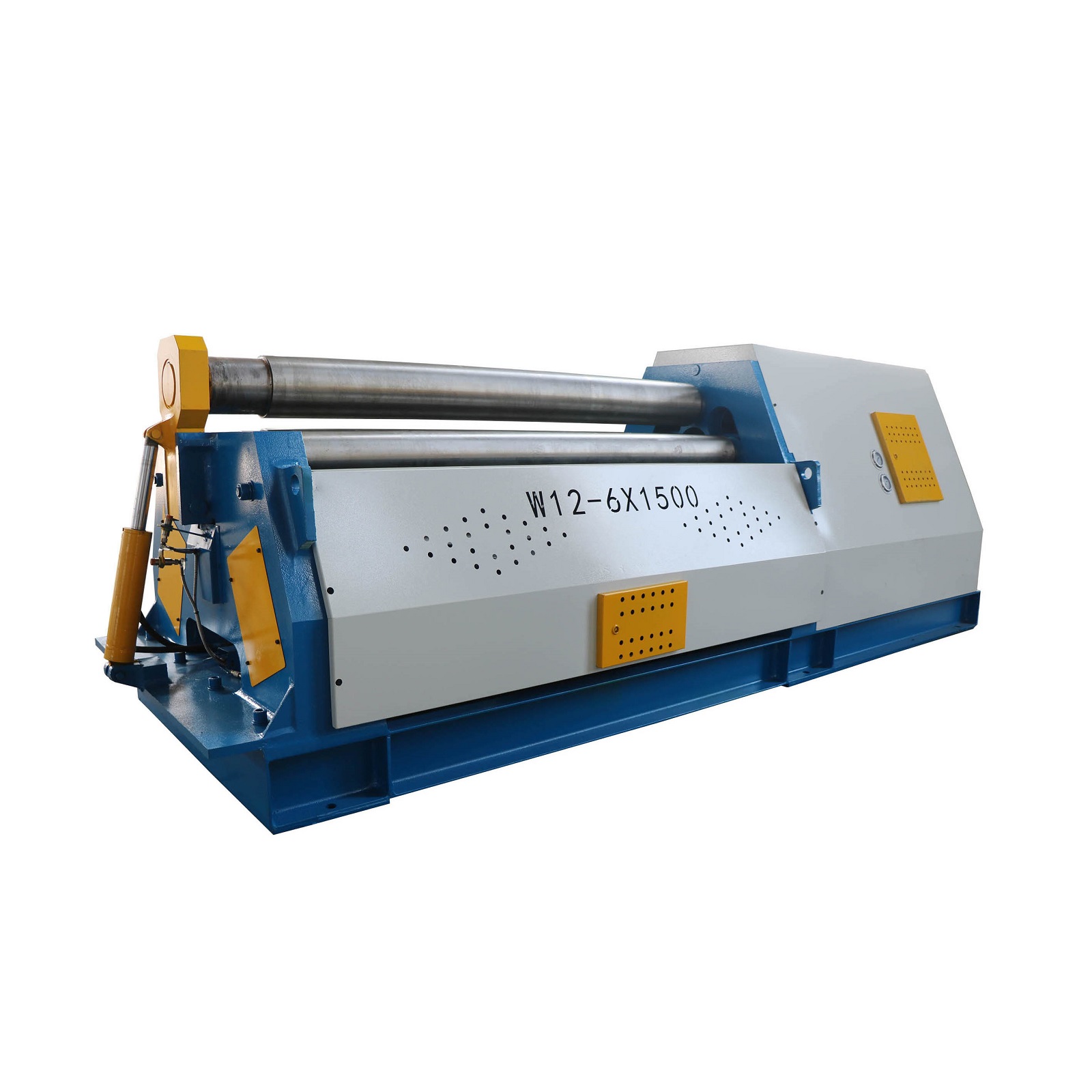

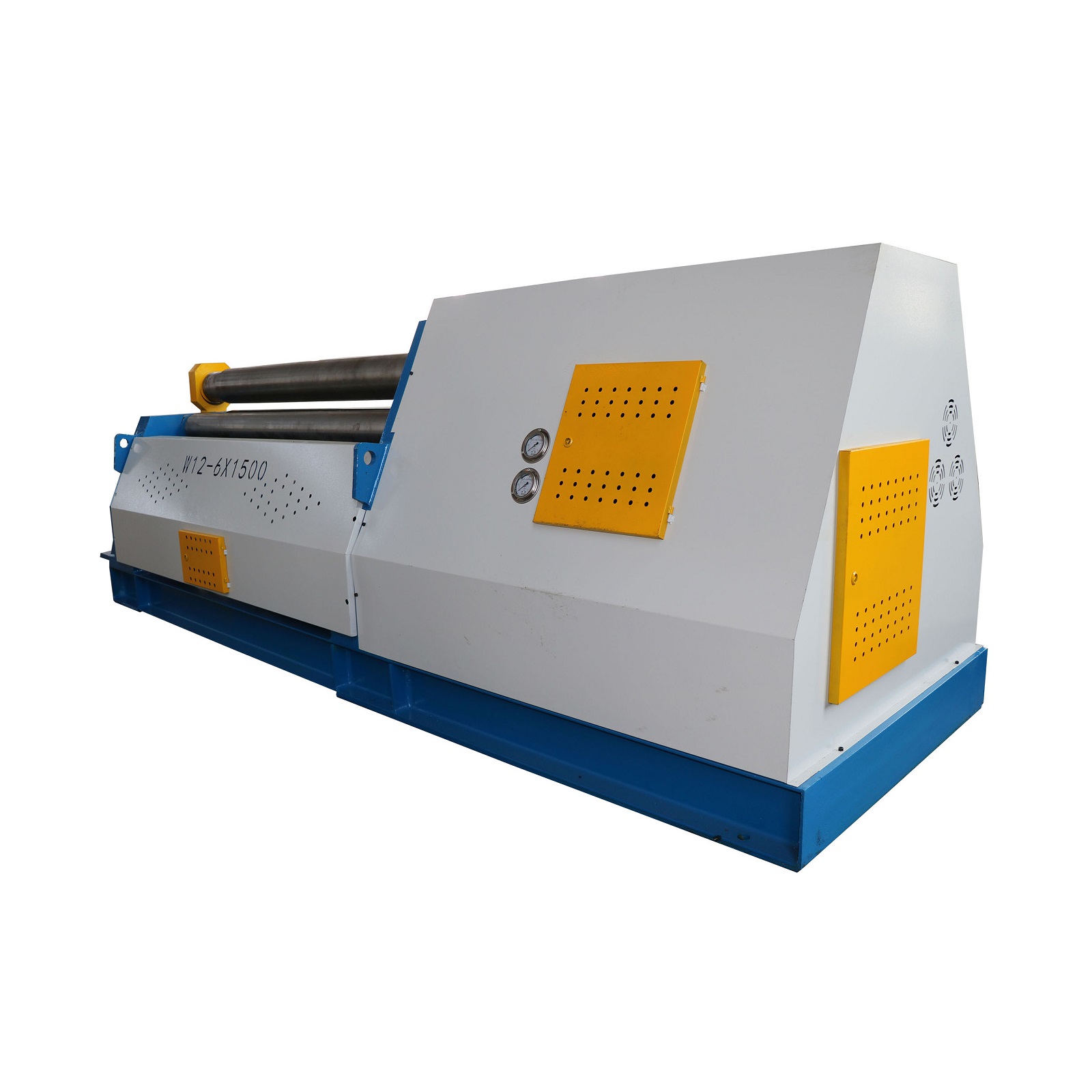

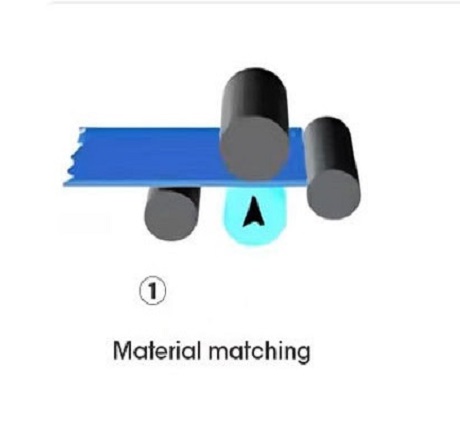

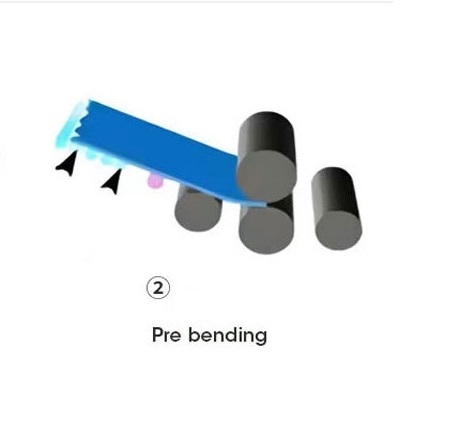

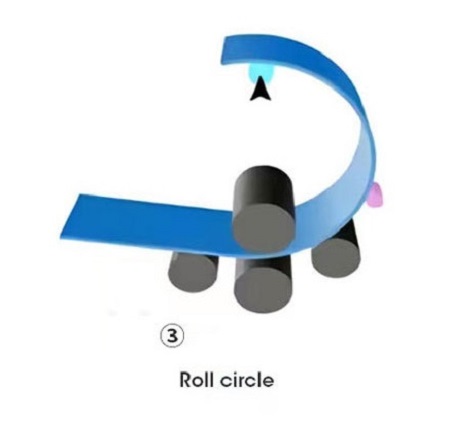

Working Principle of the CNC 4-Roller Plate Bending Machine

Key Features

- Full Hydraulic Drive: Provides higher safety, stability, and efficiency, with up to 60% energy savings compared to traditional machines.

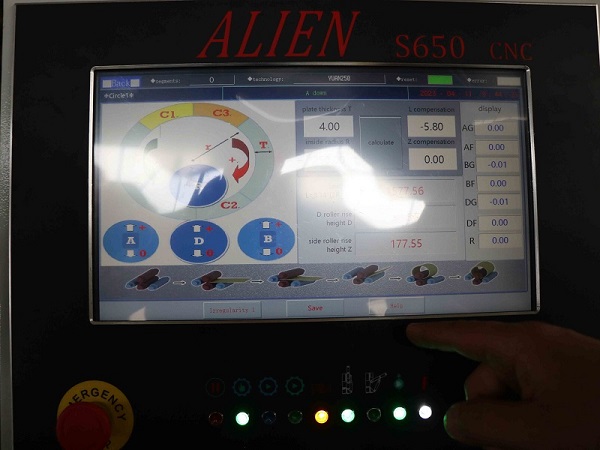

- Programmable Control: Features a PLC-controlled system for automated, precise operation with a touchscreen interface and digital display.

- Advanced Clamping System: Adjustable pressure via hydraulic station valve ensures no slippage during rolling, increasing productivity by 50–80%.

- High Precision Pre-Bending: Capable of rolling cylinders with diameters as small as 1.3x the upper roll diameter, minimizing straight edge after pre-bending.

- Permanent Lubrication System: Ensures maintenance-free bearing life with automatic lubrication and block alarm.

CNC 4 Roll Bending Machine-Applications

This machine is suitable for bending and forming metal sheets into cylindrical, arc-shaped, and conical workpieces.

- Manufacturing & Fabrication

- Boiler and Pressure Vessel Production

- Chemical Processing

- Non-metallic Structure Fabrication

- Machine Building Industry

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.