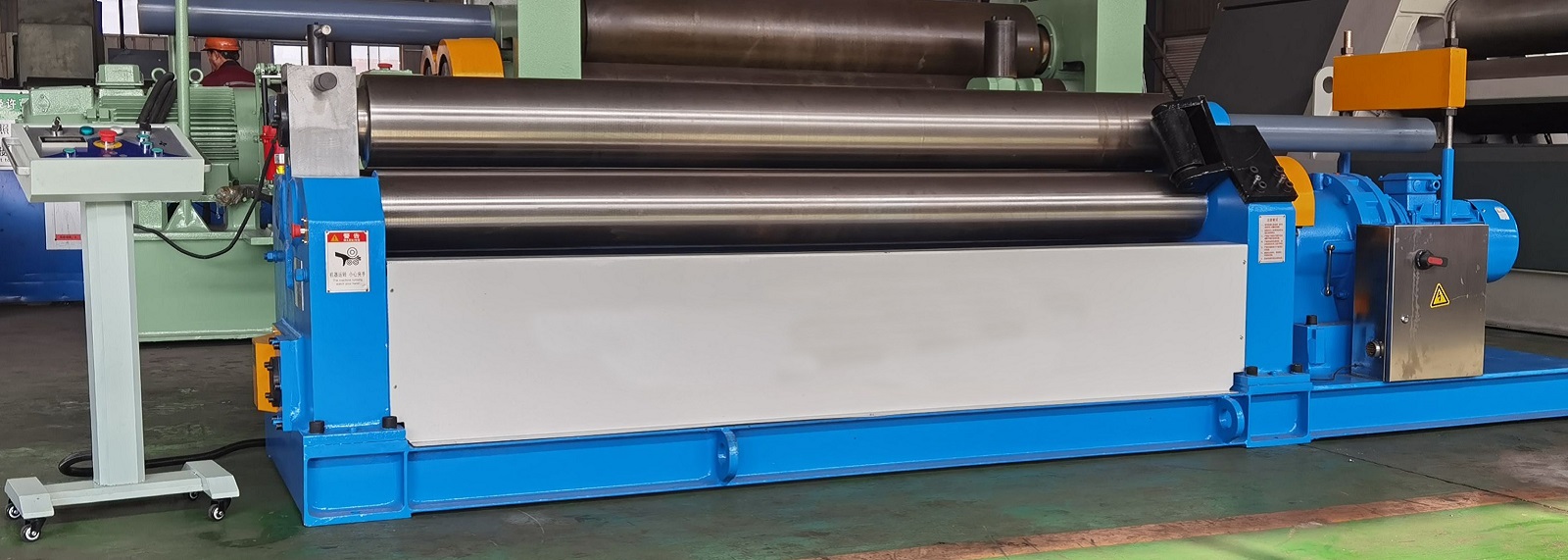

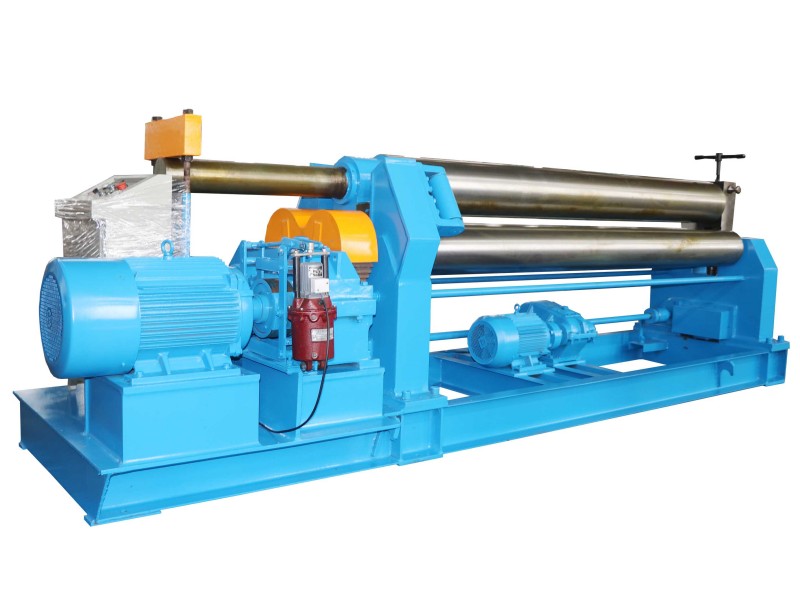

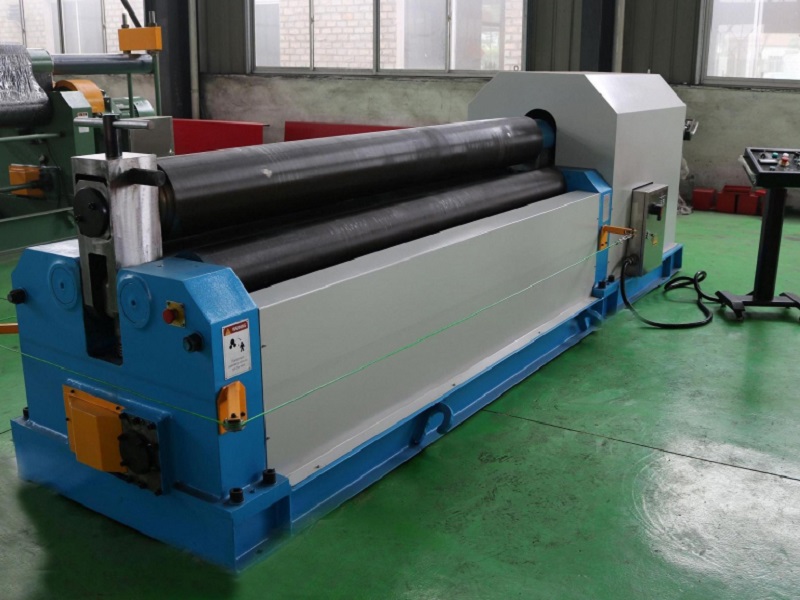

AEK-W11 Series CNC 3-Roller Symmetrical Plate Rolling Machine

- Easy Operation: The detachable console makes it easy for operators to control and achieve precise positioning, enhancing the accuracy and efficiency of plate rolling.

- Wide Application: Suitable for a variety of materials, including carbon steel, stainless steel, and aluminum alloys, making it ideal for industries requiring diverse bending needs, including circular, arc, and conical shapes.

- Durable Design: Hardened and surface-treated rolls allow for rolling of various material types, ensuring long-term reliability and performance.

- CNC Equipped: The first in its class to feature CNC capabilities for producing unit and serial parts with high precision.

Performance Highlights:

- Pre-Bending: Integrated pre-bending functionality ensures perfect edge control during the rolling process.

- Heavy Duty: Capable of handling large thicknesses with exceptional bending force, offering 15% more pre-bending power than 4-roll machines of similar capacity.

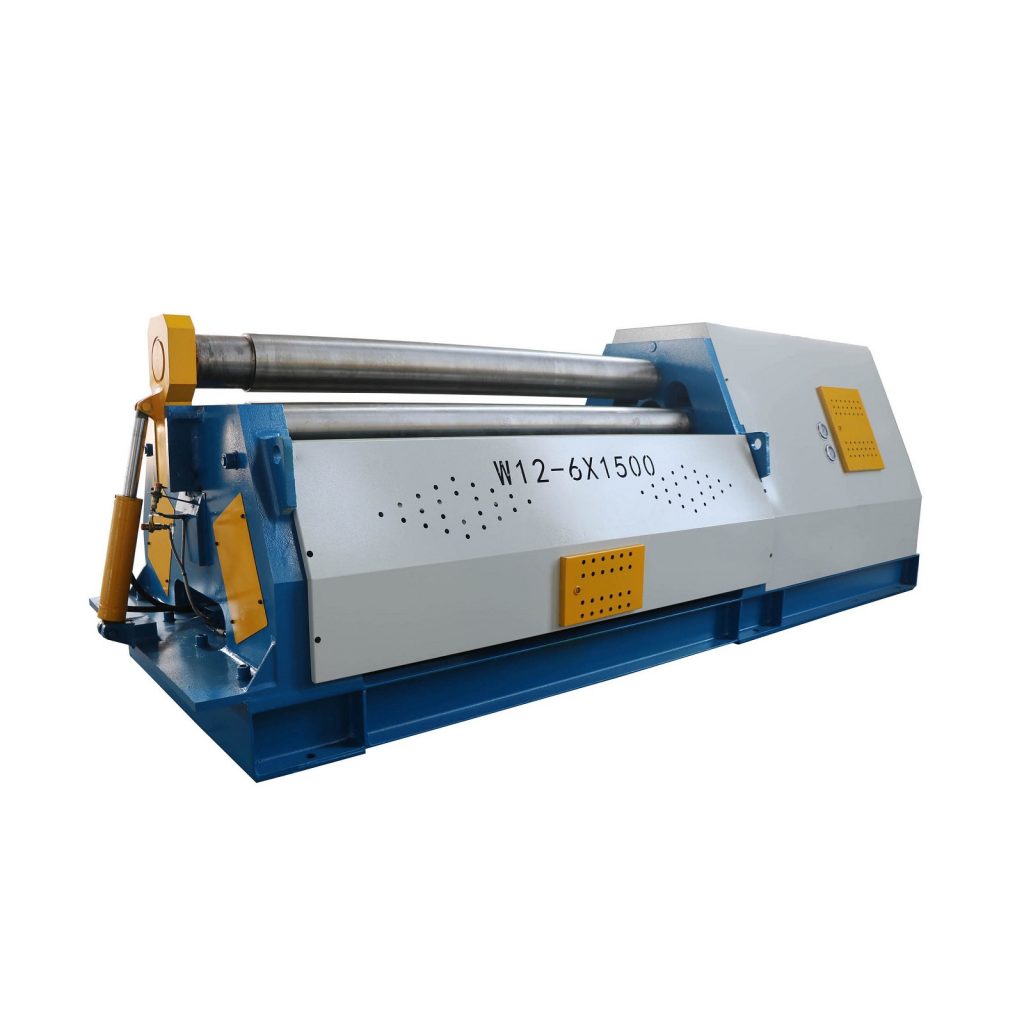

OEM Customization for AEK-W11 Series CNC Plate Rolling Machine

We offer OEM customization for the AEK-W11 Series CNC 3-Roller Plate Rolling Machine to meet your specific operational needs.

Features:

- Highly Productive and Accurate: Designed for optimal productivity and precision with minimal operational costs.

- Energy-Efficient: Operates with less energy while maintaining top-tier performance.

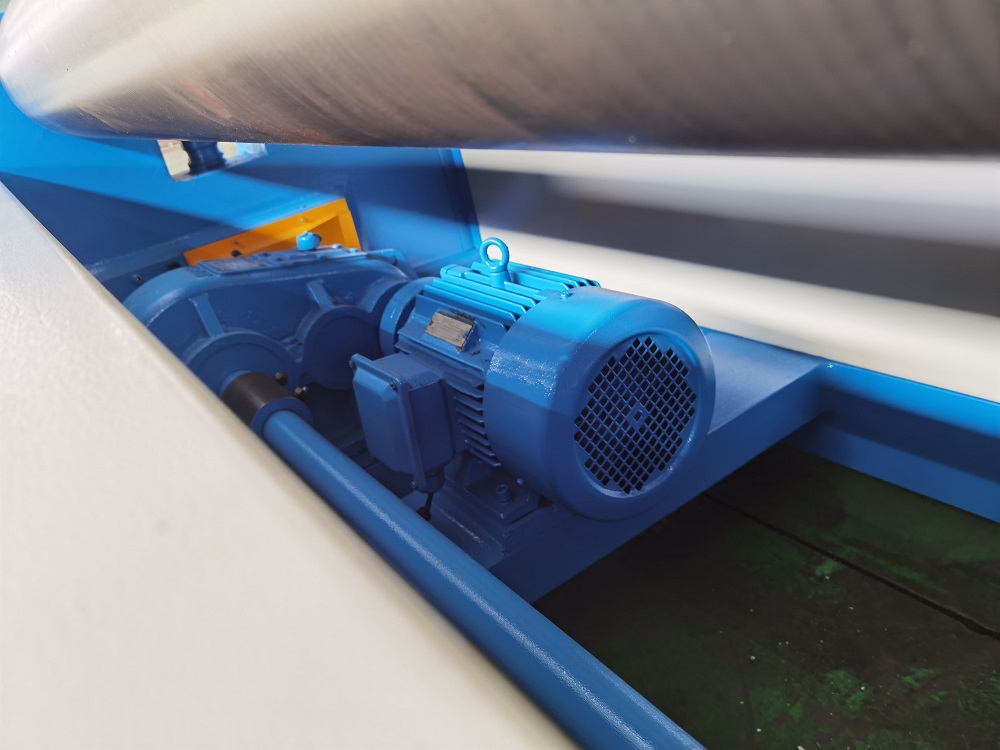

- Mechanical Drive: The two lower rollers serve as the driving rollers, while the upper roller is driven for efficient operation.

- Main Motor and Gearbox: Equipped with a powerful motor and gearbox for stable, consistent power output.

- Separate Control Panel: An easy-to-use control panel with a digital readout for simplified operation.

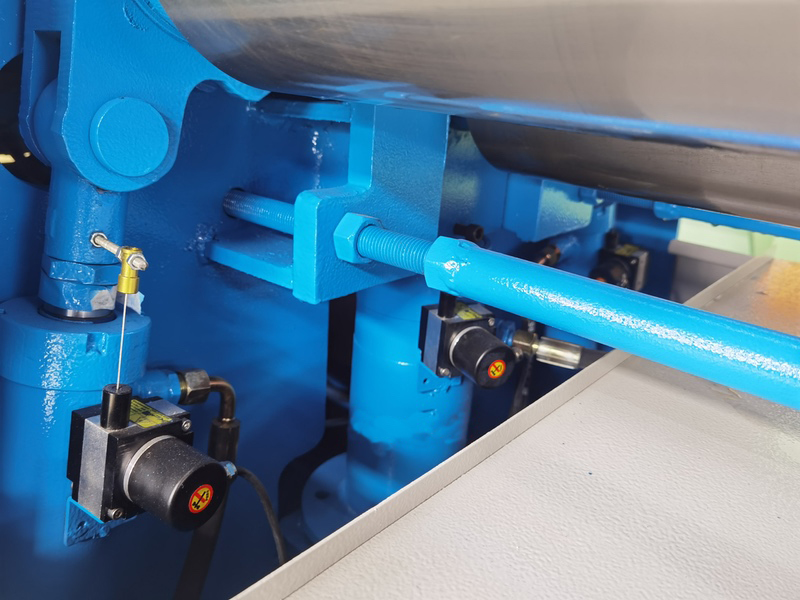

- Manual Drop End: Simple end-of-operation control for easy material handling.

- Durable Rolls: High-quality steel (45) rolls for improved durability and performance.

- Support Roller: Ensures even and precise rolling by compensating for any potential misalignment.

Optional Features:

- Cone Bending Device: This is used to produce conical shapes with ease.

- Hydraulic Reversal Frame: Provides additional flexibility for reversing the direction of the roll.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.