Application of C Purlin Roll Forming Machine

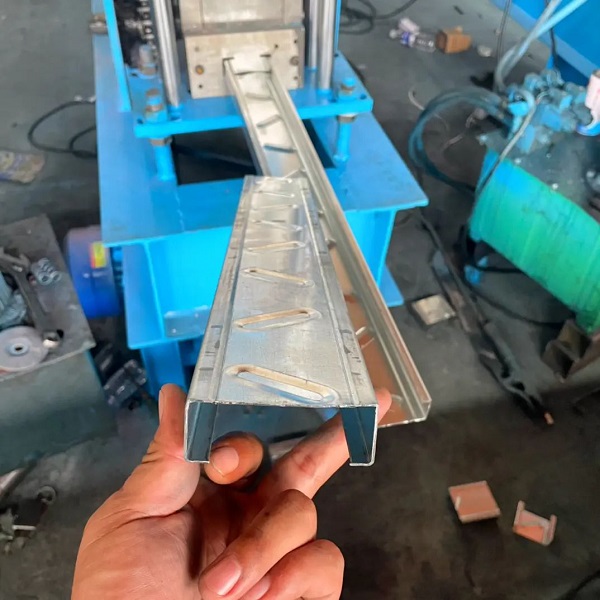

Construction industry: can be used as wall support, beams, roof trusses, columns, brackets, steel structures, etc.

Decoration engineering: can be used in construction and decoration engineering, such as door and window frames, guardrails, billboards, etc.

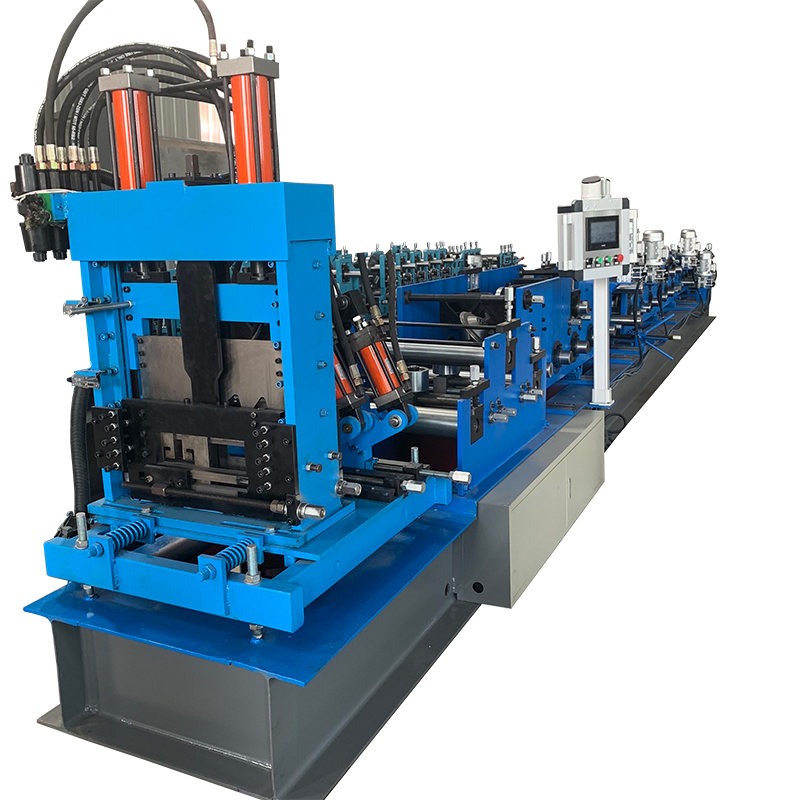

It is mainly composed of a passive loading rack, leveling device, punching device, post-forming cutting device, hydraulic station, computer control system, etc.

Features

Servo shear chasing system

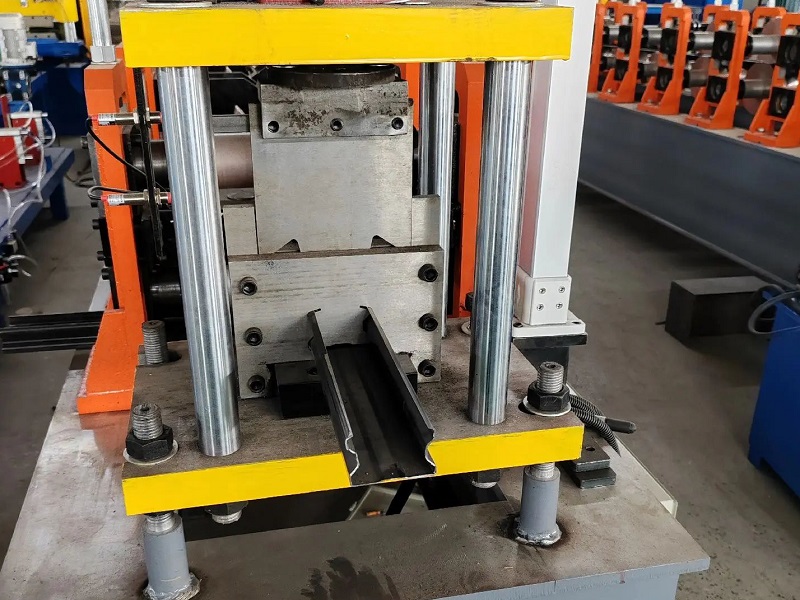

Servo shear chasing systemBuckle wheel assisted buckling C-beam machine through the buckled wheel-assisted buckling angle is more standard, and does not scratch the surface of the board.

PLC control

PLC controlAdopting fully automatic computer control, and automatic control, realizing production information management.

Buckle wheel auxiliary buckle

Buckle wheel auxiliary buckleConvenient maintenance with operation and maintenance, maintenance and mechanical debugging, easy-to-replace molds, etc.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.