Customized Embossing Patterns

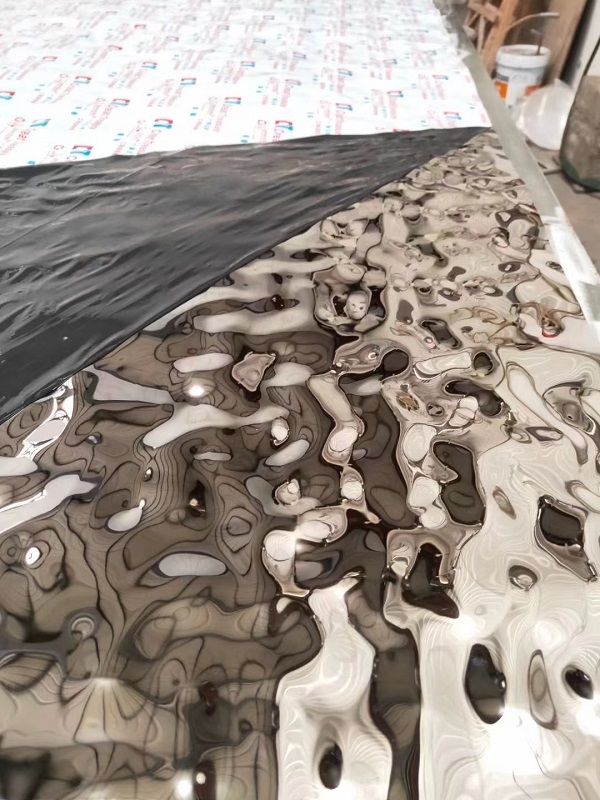

- Wavy Pattern

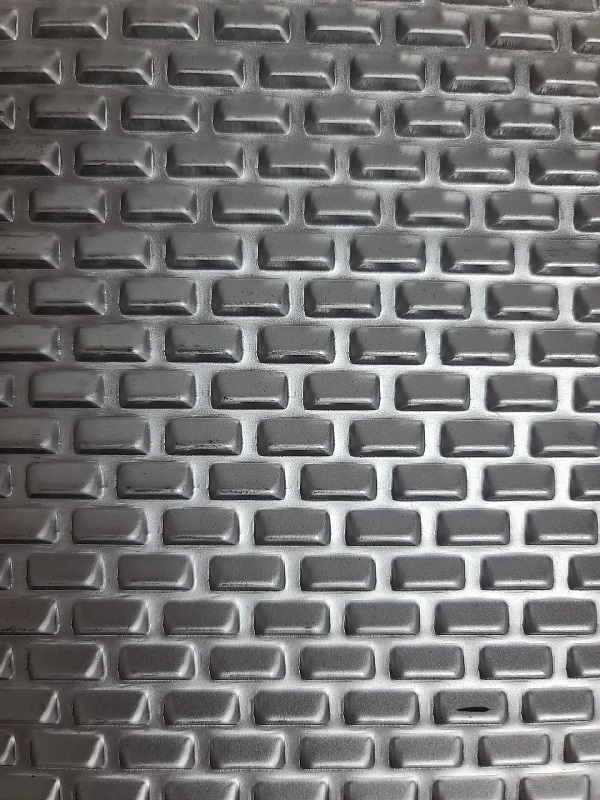

- Grid Pattern

- Diamond Pattern

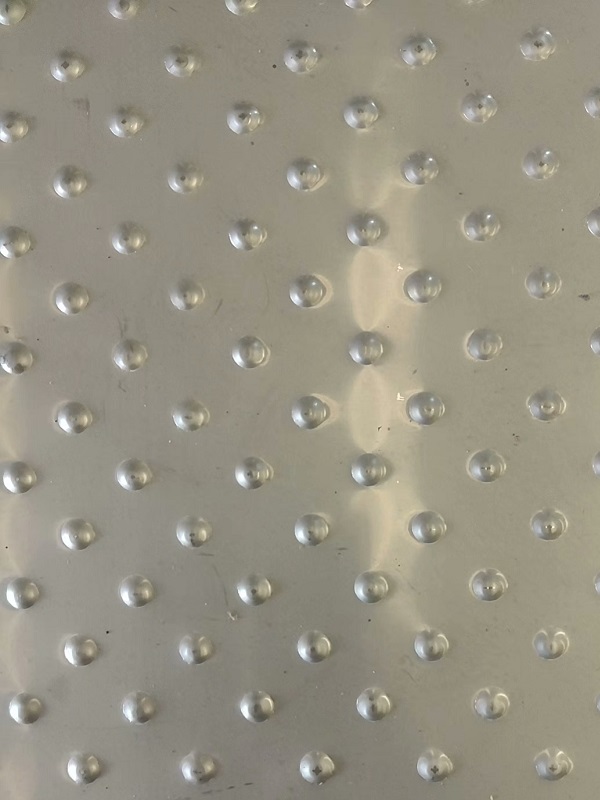

- Dot Pattern

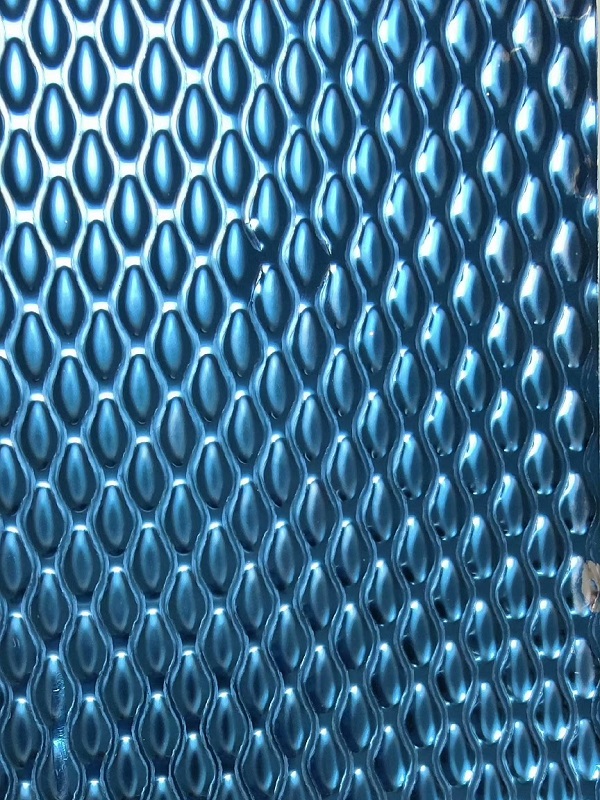

- Leaf Pattern

- Stripes Pattern

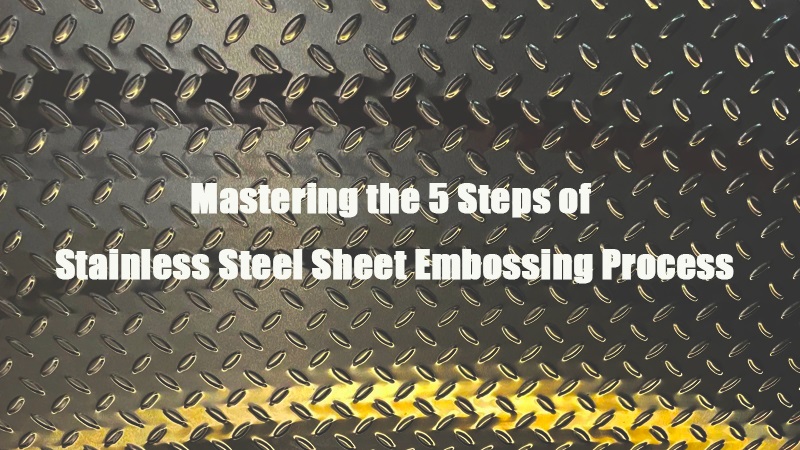

Metal Plate Embossing Machine Rolling Machine Production Line

380V/50HZ, 15KW power support, 1-60m/min variable frequency speed regulation

Siemens hydraulic system accurately adjusts embossing pressure

Sheet Metal Embossing Machine Production Line Composition:

- Automatic Uncoiler with Hydraulic Trolley: Automatically unloads metal coils.

- Automatic Embossing Machine: Equipped with customized embossing rollers, supports pressing various patterns.

- Automatic Recoiler with Hydraulic Trolley: Ensures the neatly recoiled metal sheets after embossing.

- Hydraulic Station: Provides stable hydraulic power required for the embossing system.

- Control Cabinet: Centralized control of all equipment operations, enhancing safety.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.