The double-head material rack is a new type of unwinding equipment specially developed to improve the efficiency of the stamping production line.

It also has the advantages of high-speed feeding and non-deformation feeding. It is particularly suitable for matching with S-type leveling machines, gear feeders, and high-speed punching machines to form a high-speed synchronous stamping production line, and is used for the stamping of motor stators and rotors and EI sheets.

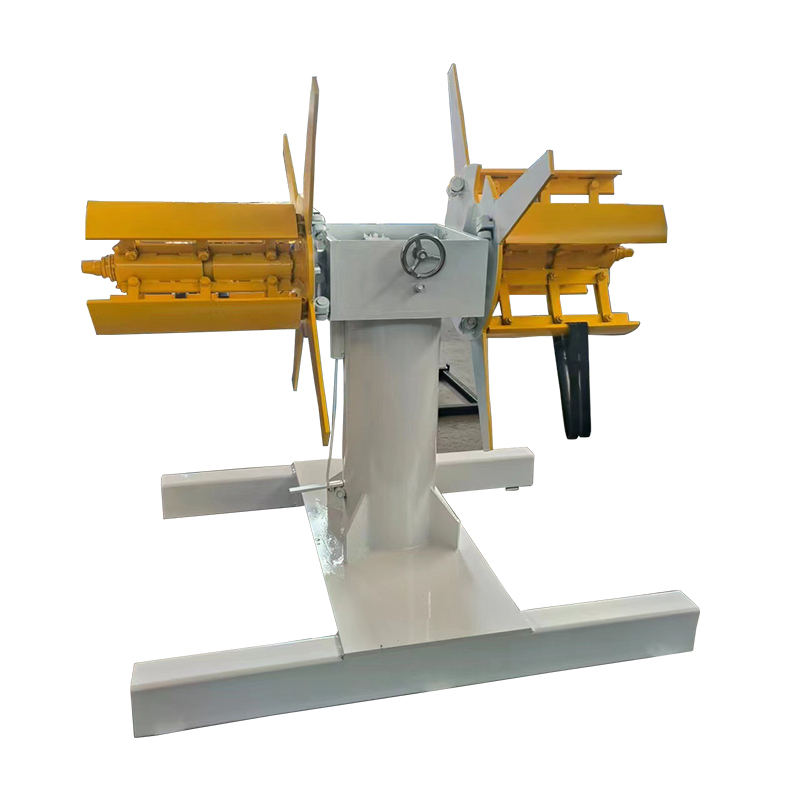

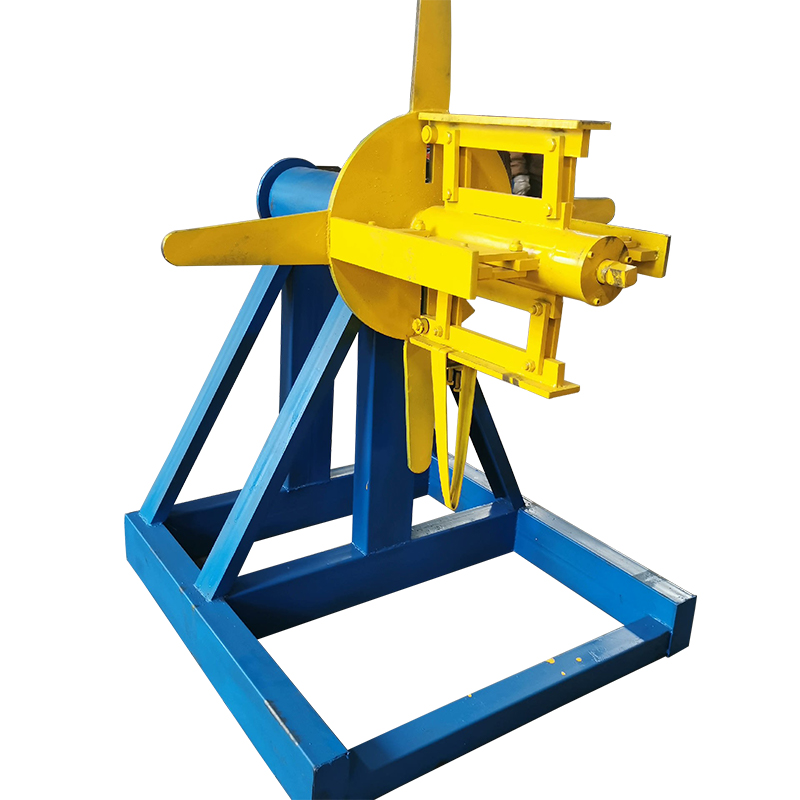

The double-head structure design can load two coils at the same time. When one coil is used up, you only need to turn around to change the coil. The coil change is fast, which improves production efficiency and keeps unwinding in sync with the production speed.

- Through the compression nut, hinged rod, sleeve, etc., the expansion and contraction of the support plate can be achieved, and the coil can be tightened and relaxed. The structure is simple and novel.

- With a damping device to control the unwinding speed, the unwinding is stable.

- Long wheelbase support, exquisite structure, large load, convenient loading, flexible use.

Double Head coil decoiler Machine Optional-Sensor bracket

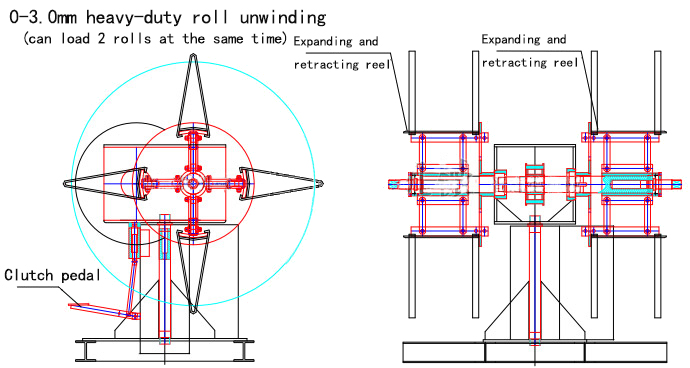

Schematic diagram

Double Head coil decoiler Machine Optional-support arm

1.Material pressing support arm 2.Material supporting support arm 3. Material blocking support arm

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.