$6300.00$6100.00

(Reference Price)

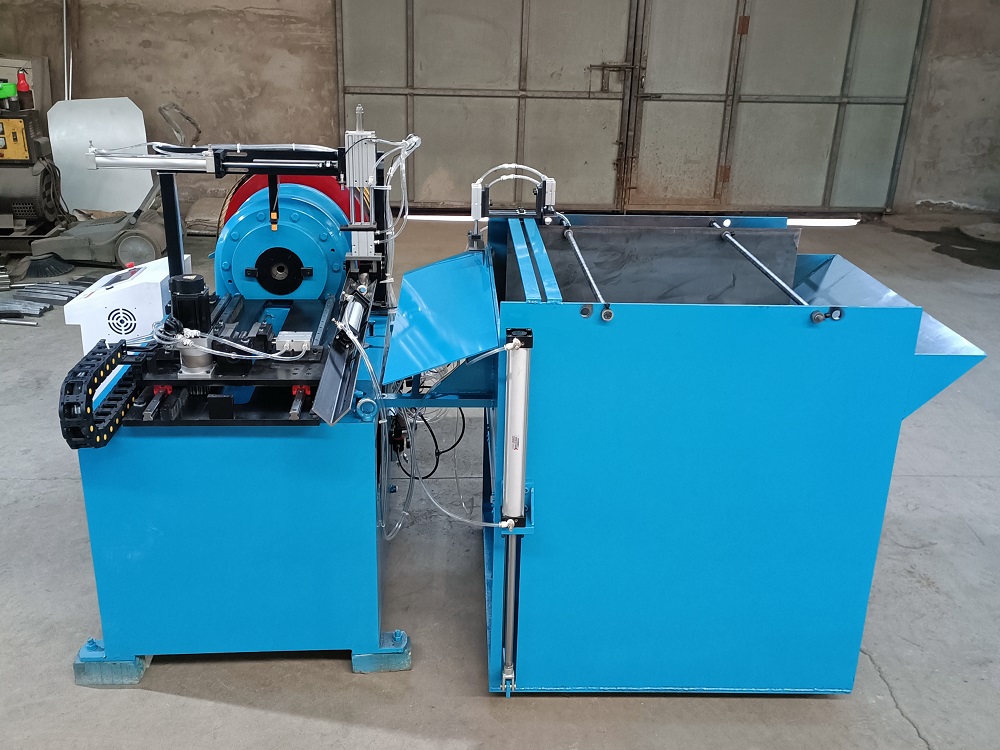

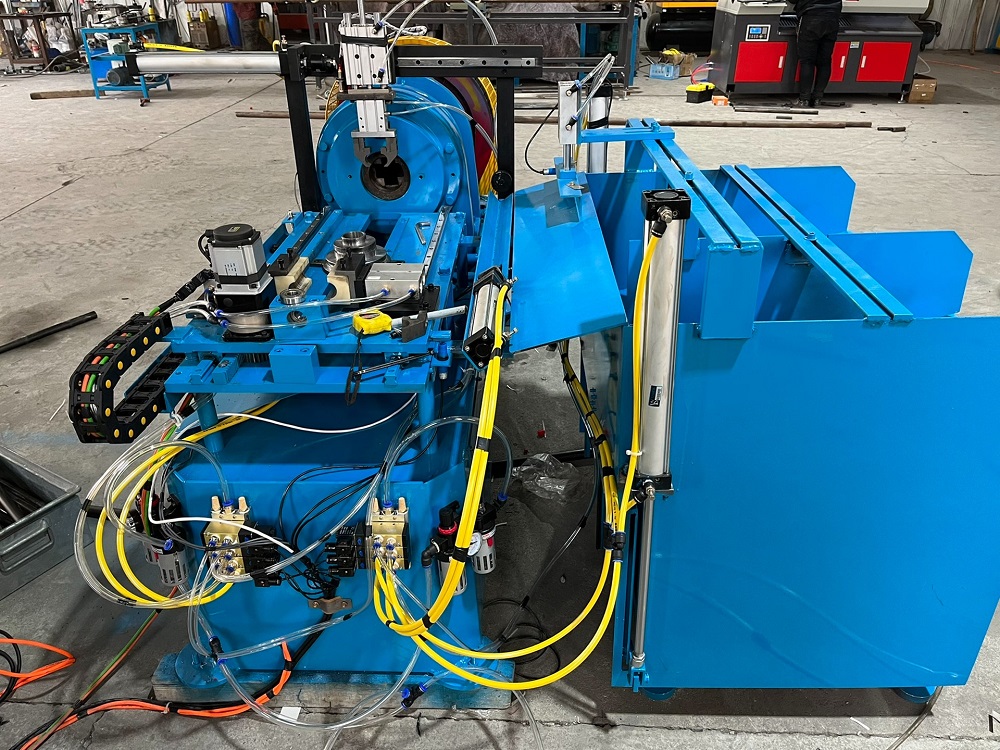

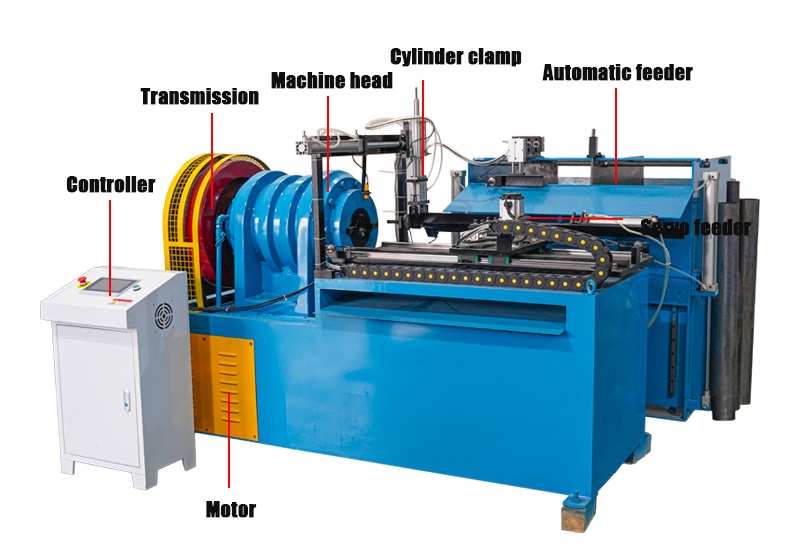

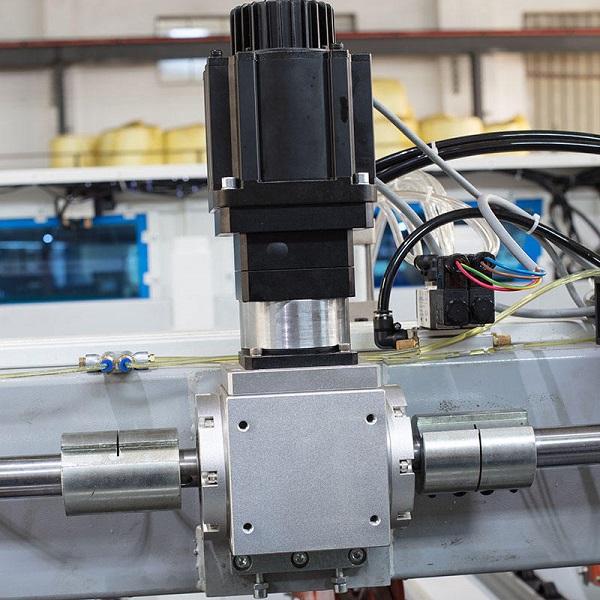

The ALEKVS Automatic CNC Pipe and Tube Tapering Machine efficiently processes metal tubes into precise conical shapes with smooth, scar-free surfaces and features automatic loading and unloading.

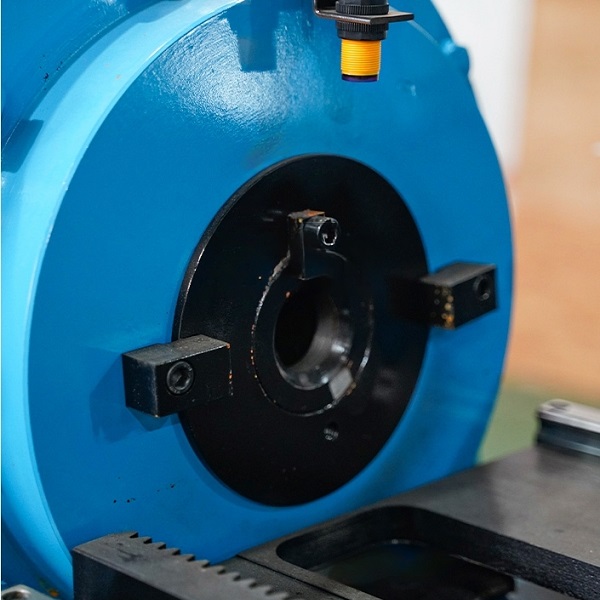

Easily interchangeable molds for processing various shapes, including convex, concave, long flat, square, V-shaped, open elbow, and flat elbow ends.

- Customizable Processing: Supports pipe thicknesses specified by the client, ensuring adaptability to diverse needs.

- Wide Range of Applications: Suitable for pipe fittings and connecting parts in various industries.

- Precision and Efficiency: Meets the requirements for accurate pipe tapering and diameter reduction across various industrial applications.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.