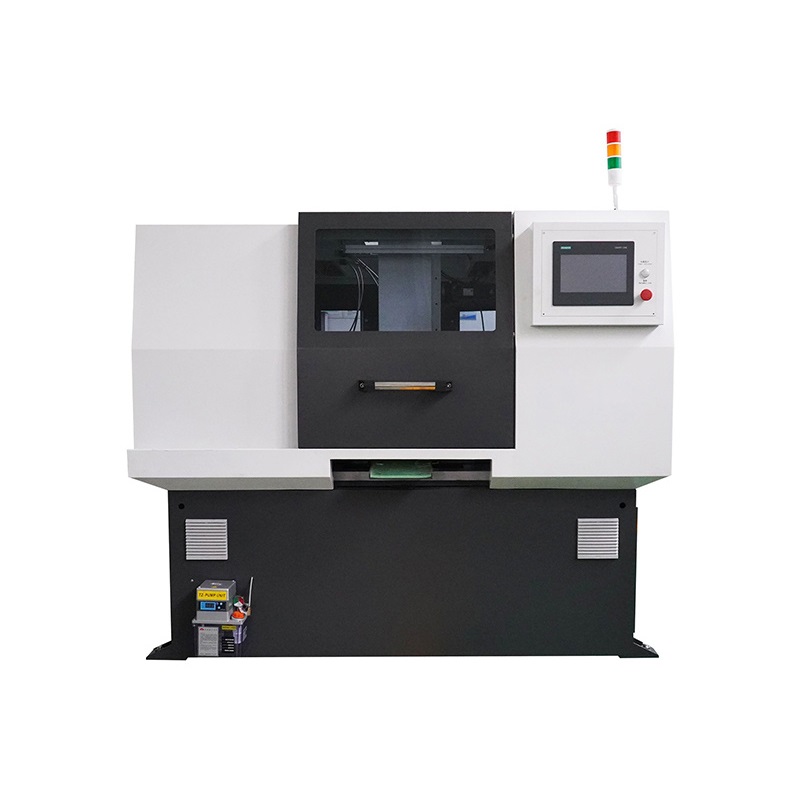

Automatic CNC Double Head Chamfering Machine Applicable Materials:

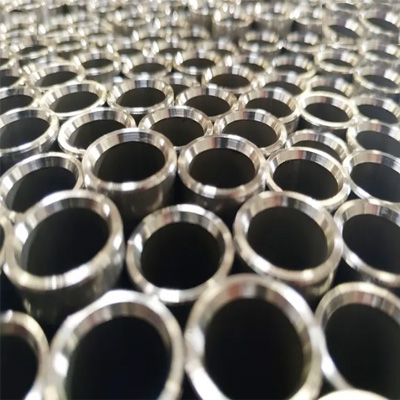

Compatible with various materials, including steel pipe, iron pipe, aluminum pipe, stainless steel pipe, and PVC pipe.

Features of the Automatic Double-Head Chamfering Machine:

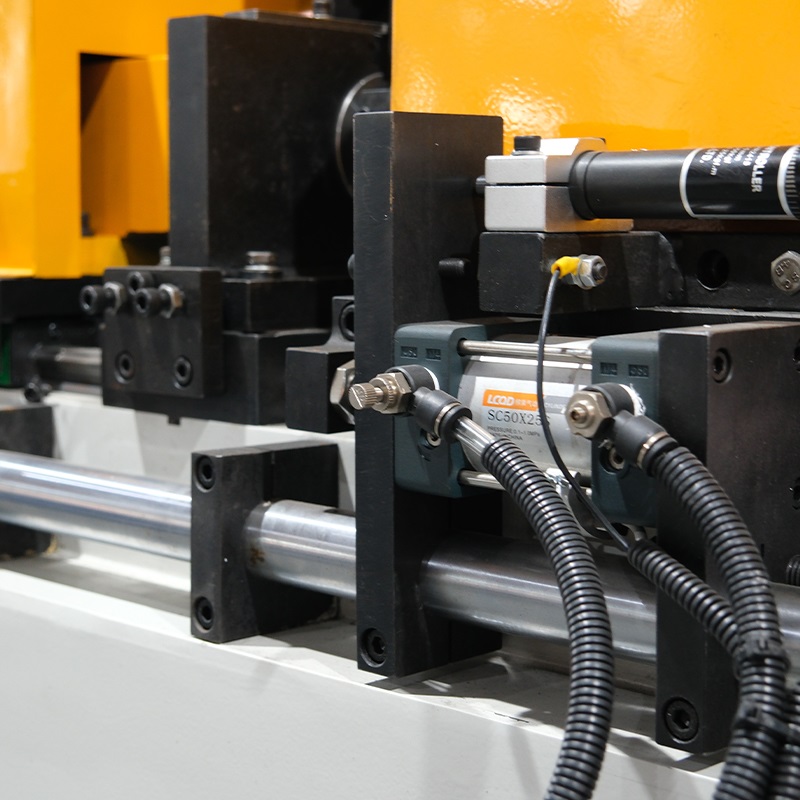

Control System:

- Equipped with an imported PLC (computer-controlled) main circuit for efficient operation.

- Servo motor-driven ball screw ensures high-precision feeding.

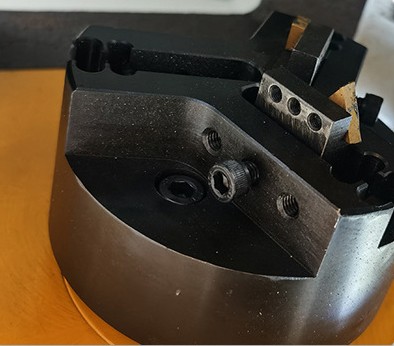

Clamping and Cutting Design:

- Features exquisitely designed clamping molds and cutting tools.

- Maintains the center accuracy of the processed object and cutter head.

- Capable of evenly completing the outer corner of the pipe end in one go.

Machining Accuracy:

- Ensures machining dimensional accuracy of ±1 mm for internal corners and end faces.

- Feed speed is adjustable (fast or slow), with a buffering function at the limit to enhance tool life and processing quality.

Key Advantages:

- Specially Designed Feeding Mechanism:

- Facilitates easy and time-saving type switching.

- Enhanced Blade Design:

- Features stable blade installation with super-strong blades.

- Customized hard alloy cutting tools extend tool life.

- Dual-Stage Feed Speed:

- Saves labor hours by enabling stage-adjustable slow feed for precise machining.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.