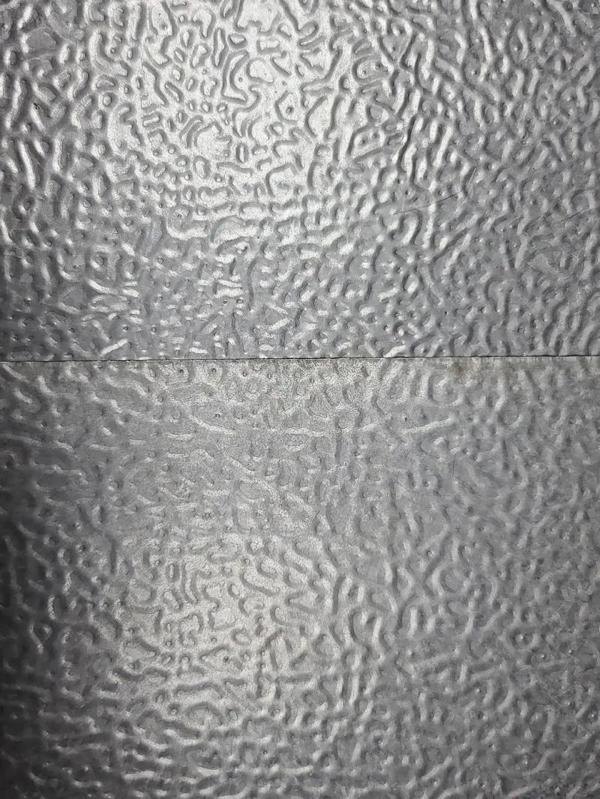

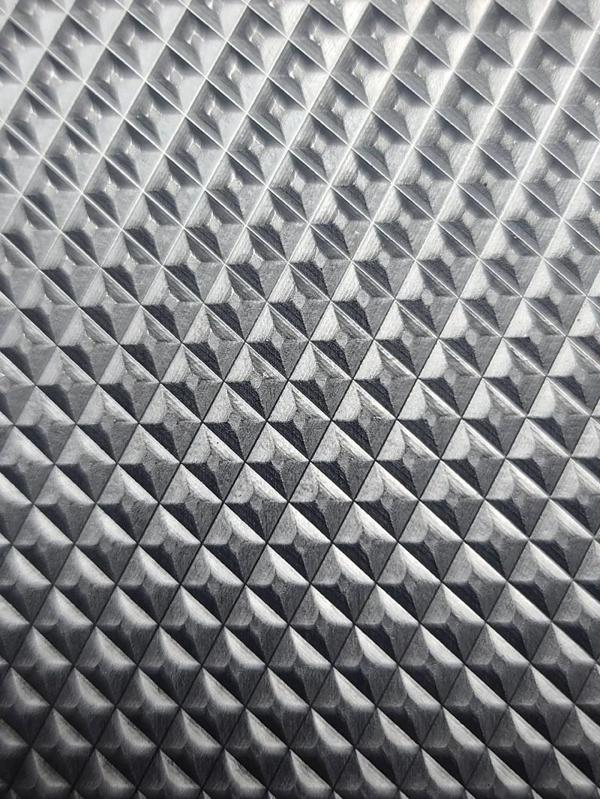

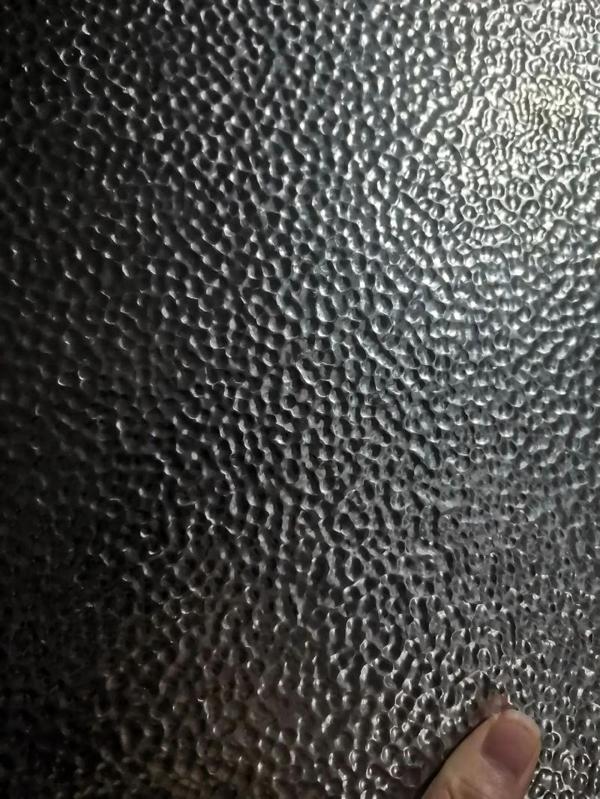

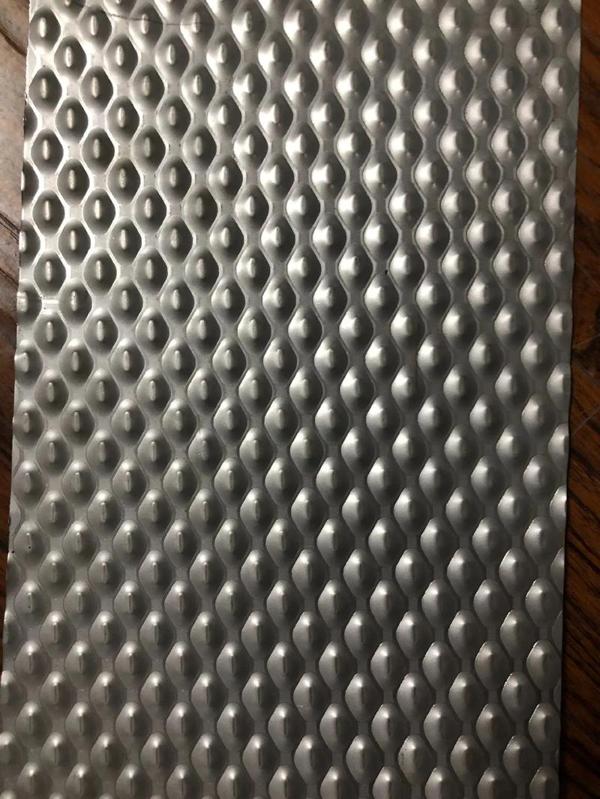

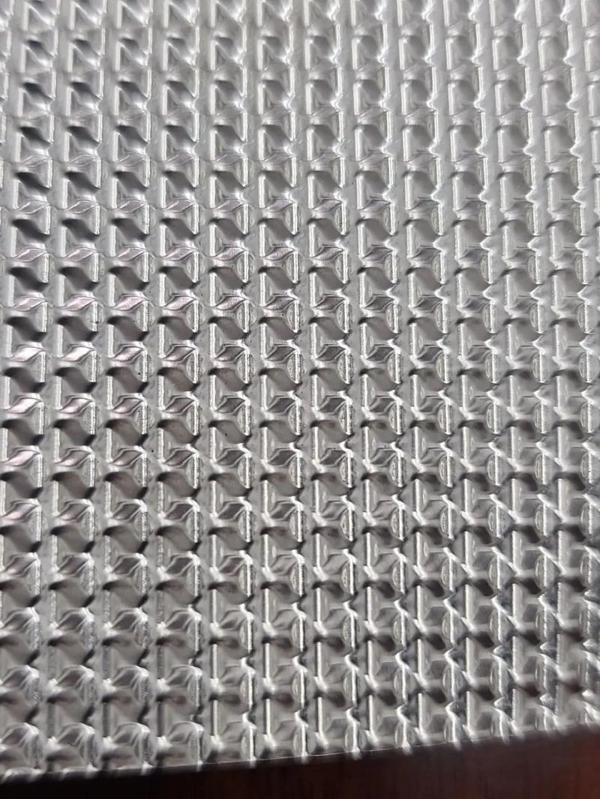

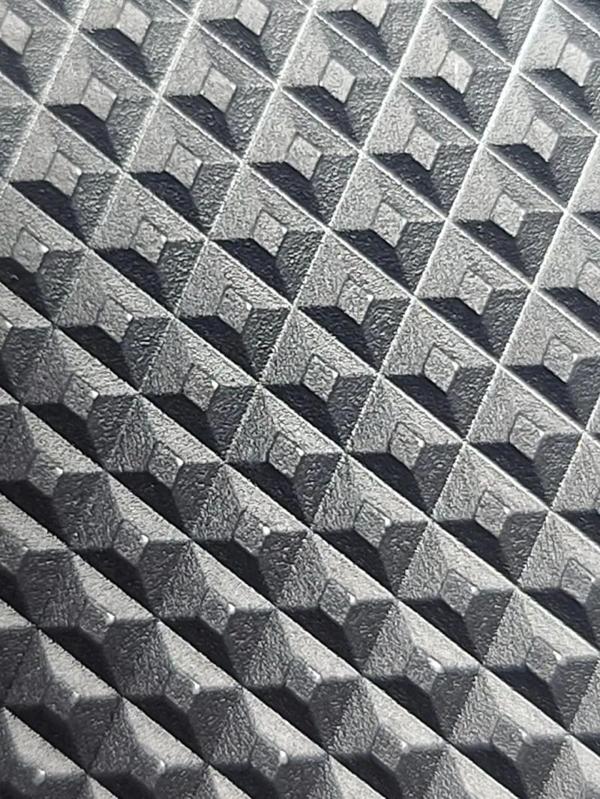

The principle of the metal embossing machine is the use of embossing machine will be placed on the metal plate between the two embossing mold rollers, under a certain pressure and temperature to make the surface of the material deformation of the technology, smooth steel plate in the machine rolled over into a concave-convex neat patterned plate.

- Precision Embossing: Customized patterns are available according to your needs, with adjustable pattern depths ranging from 1mm to 2mm.

- Durable construction: The integral forging of the roll structure ensures outstanding strength and longevity.

- Enhanced performance: Roll bodies are medium frequency hardened to HRC52-55.

- Robust Frame: The mill frame’s steel plate composite structural members provide a solid foundation for demanding operations.

- Variable speed control: Using variable frequency speed control allows for precise fine-tuning control of the embossing process.

- Flexible pressure regulation: A pressure regulator system for pressure reduction enables you to achieve the desired level of embossing detail.

- Separate control cabinet: The electrical control section is installed separately for increased safety and easy maintenance.

- ADJUSTABLE ROLLER GAP: The gap between the rollers can be easily adjusted to accommodate a variety of material thicknesses.

- Removable and Replaceable Flower Rollers: Allows for quick and easy pattern customization.

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.