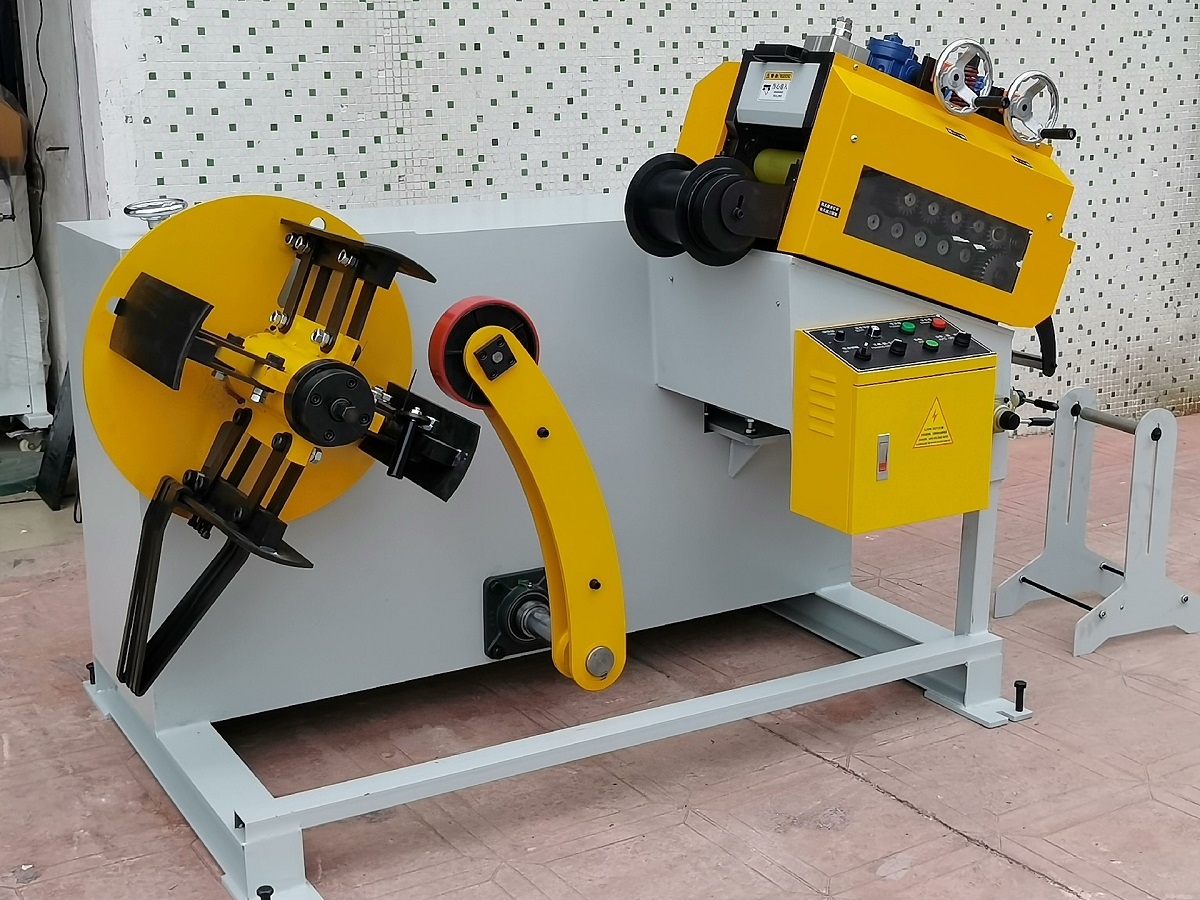

Key Features of 2-in-1 Decoiler and Straightener Machine

- High-Precision Straightening Performance: Equipped with 7 hardened rollers (4 upper, 3 lower) made from heat-treated, hard-chrome plated GCr15 alloy steel (HRC58–62) for excellent durability and scratch resistance.

- Stable & Independent Control System: Separate motor control cabinets with individual inverters ensure smooth operation and prevent interference.

- Reliable Drive Mechanism: Universal joint and gear transmission reduce wear and minimize the risk of damage from passive roller rotation.

- Quick & Easy Adjustment: Dial indicators enable fast leveling point identification and accurate straightening adjustments.

- Wide Material Compatibility: Suitable for HR, CR, stainless steel, aluminum, and galvanized steel coils.

- Durable & Rigid Construction: CNC-machined components ensure structural strength and long-term stability.

- Flexible Feeding Control: Automatic feeding synchronized with line speed for efficient operation.

- Easy Maintenance & Safety Features: optional press arm, protective covers, and safety sensors available.

Typical Application Line

- Step 1: Decoiler Straightener – loads and straightens coil

- Step 2: NC Servo Feeder – feeds coil into press

- Step 3: Power Press – performs stamping operation

Customizable Options

Available with hydraulic decoiler expansion, pneumatic press arm, AC motor with inverter, and various configurations to meet specific production needs.

Optional Parts

- Pneumatic press arm

- Hydraulic expansion mandrel

- AC motor + inverter

- Loop control system

- Remote control handle

Decoiler and Straightener Used widely in:

- LED parts

- Automotive stamping

- Electronics and appliance components

- General metal hardware production

Please fill out this form to submit a request for quote. One of our team members will review the details and be in touch within 12 business hours.